Common Materials and Applications in the Flexible PCB Industry

Date: 2025-08-09

- Substrates: Polyimide (PI) stands as the industry standard, prized for its ability to handle temperatures up to 300°C while maintaining flexibility—critical for high-heat environments like automotive engine bays or industrial machinery. Its chemical resistance also makes it ideal for medical devices exposed to sterilization fluids. PET (polyethylene terephthalate) offers a budget-friendly alternative, though it struggles with extreme heat, finding use in low-power gadgets like remote controls or basic sensors.

- Conductors: Copper remains the primary choice, with two common forms: rolled copper (for superior flexibility in repeatedly bent devices like foldable phones) and electrodeposited copper (better for fine, dense circuits in wearables). For harsh environments—such as marine equipment or outdoor sensors—gold-plated copper adds a protective layer, resisting corrosion from salt, moisture, or chemicals.

- Adhesives & Cover Layers: Epoxy adhesives bond substrate layers, striking a balance between flexibility and structural strength. In high-performance scenarios—like aerospace electronics—adhesive-free designs reduce thickness and improve heat dissipation. Cover layers, often made from PI or PET, shield copper traces from physical damage and dust, ensuring long-term reliability in daily-use devices.

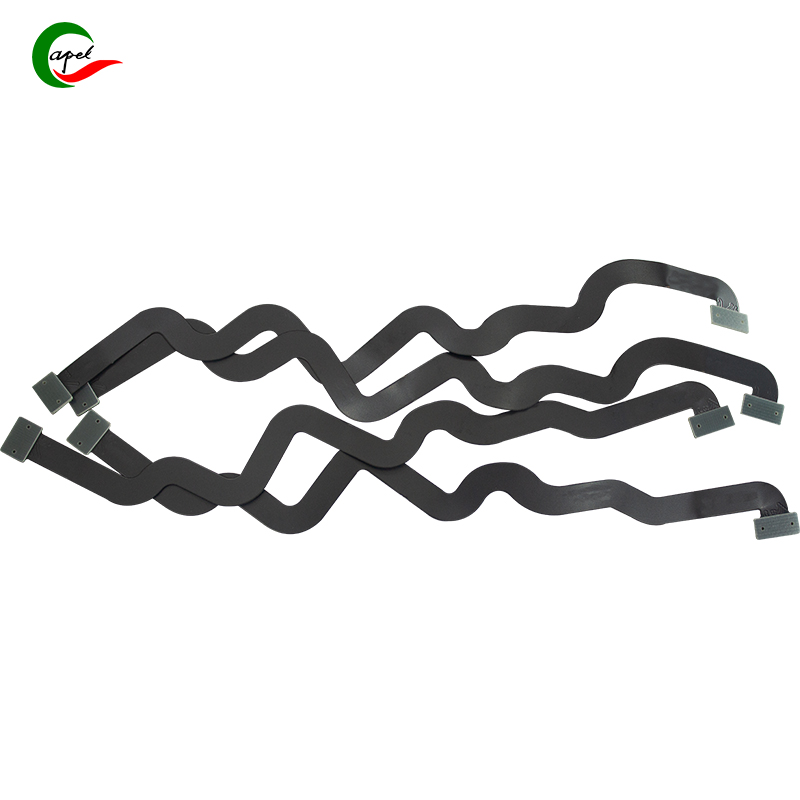

- Consumer Electronics: From smartphones (where they connect curved screens to motherboards) to wireless earbuds (fitting tiny circuits into compact casings), flexible PCBs enable sleek, portable designs. They’re also key in smartwatches, routing signals between touchscreens, heart rate monitors, and batteries without adding bulk.

- Automotive Systems: Modern cars depend on them for infotainment (linking touchscreens to speakers and GPS modules) and safety features like ADAS—where they tuck into tight spaces behind bumpers to connect radar and cameras. In electric vehicles, they manage battery packs, monitoring cell health and balancing charge across hundreds of cells.

- Medical Devices: Their small size and flexibility make them indispensable in pacemakers (fitting into chest cavities) and portable monitors (withstanding frequent movement). Endoscopes use them to transmit images from tiny cameras, while surgical robots rely on flexible PCBs for precise, vibration-resistant signal routing.

- Aerospace & Defense: Lightweight and durable, they power avionics in commercial planes (managing navigation systems) and satellites (withstanding extreme temperature swings in space). Military gear, like night-vision goggles, uses them to maintain connectivity in rugged, high-impact environments.

By combining these materials, flexible PCBs continue to drive innovation, enabling the compact, high-performance devices that define modern life.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.