Flexible PCBs are indispensable in modern electronics, but their unique design exposes them to specific challenges during operation. Recognizing these issues is key to maintaining their performance.

Every flexible PCB has a critical "safe bend radius"—exceeding it risks irreversible harm. The polyimide substrate, while flexible, can crack under excessive pressure, and thin copper traces may snap. This is especially problematic in devices with repeated motion, like foldable phones or robotic components, where constant flexing in the same area accelerates wear. Even minor over-bending can cause intermittent issues: think flickering screens in tablets or unresponsive buttons in wearables.

Delamination occurs when layers peel apart, often due to weak adhesion between materials. Poor manufacturing (e.g., uneven lamination) or moisture intrusion are common triggers. In high-humidity environments—such as industrial facilities or outdoor gear—water seeps between layers, weakening adhesives. This disrupts electrical signals, a critical flaw in devices like medical monitors, where reliable data transmission can be life-saving.

Exposed copper traces are prone to corrosion. The protective solder mask can chip or wear away from friction, chemical exposure (e.g., oils in car engines), or extreme temperatures, leaving metal vulnerable. When copper reacts with moisture or industrial fluids, it forms oxide layers that act as insulators, increasing resistance. This can cause sensor lag in automotive systems or failed connections in kitchen appliances.

In high-frequency applications—like 5G modems or radar systems—flexible PCBs struggle with consistent signal flow. Their thin traces and flexible substrates often fail to maintain stable impedance, especially with sharp bends or uneven routing. This leads to "signal bounce" or cross-talk, which can make a radar miss obstacles or a smartphone drop calls.

Extreme temperature swings damage flexible PCBs over time. While polyimide withstands high heat, rapid shifts (e.g., from -40°F to 200°F in a car engine bay) make the substrate brittle. Adhesives soften in heat and harden in cold, speeding up delamination. Over time, this can crack solder joints or traces, causing malfunctions in critical systems like engine control modules.

With careful design (e.g., avoiding sharp bends) and protective measures (e.g., moisture-resistant coatings), these issues are manageable. Understanding their vulnerabilities ensures flexible PCBs continue to deliver on their promise of flexibility and reliability.

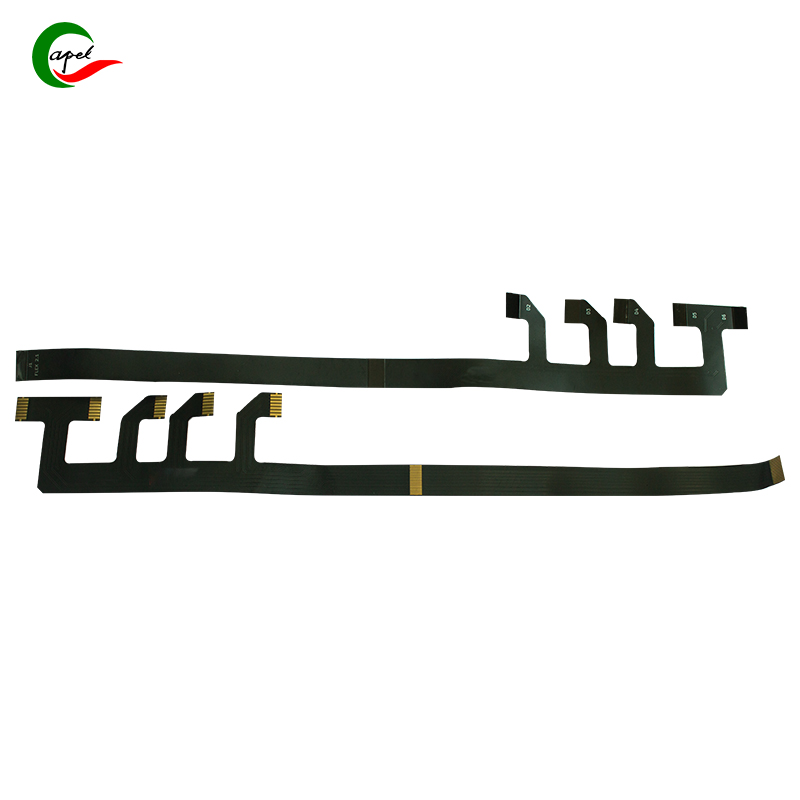

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.