Date: 2026-01-08

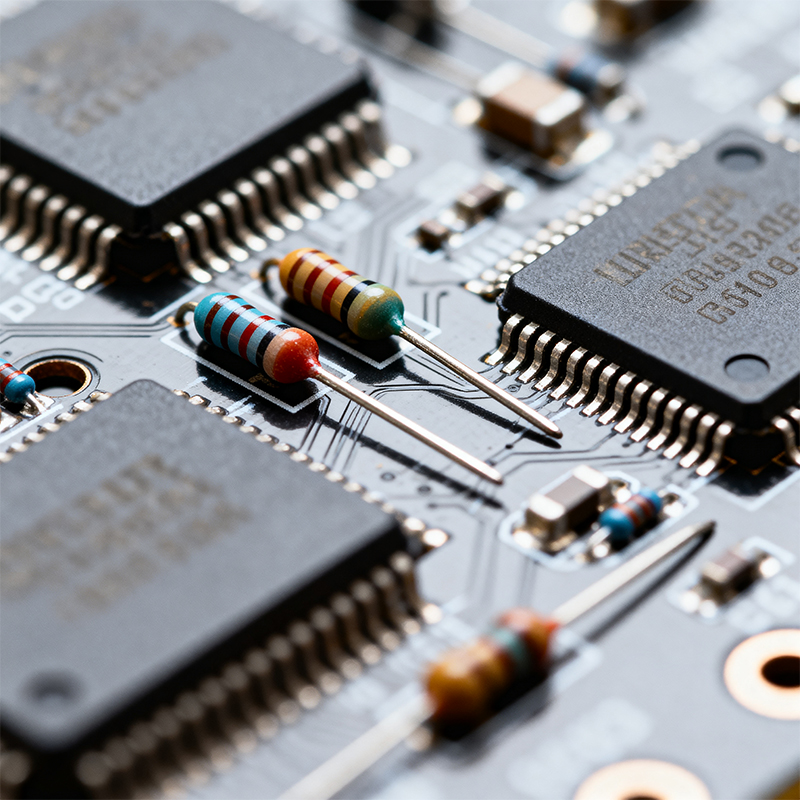

Any circuit board, if it only had the copper traces, would just be an inert piece of laminate. What gives it functionality are the various components soldered onto it.

Think of the circuit board as a plot of land with all the roads already laid out. The components are the buildings constructed on that land—factories, power stations, signal towers. They work together to make the whole system function.

There are many types of components, but they generally fall into a few main categories:

Integrated Circuits (Chips)

These are the “brains” or “command centers” on the board. From simple logic chips to complex microprocessors, they handle information processing, execute commands, and control other components.

Resistors and Capacitors

These are the most common “basic components,” found on almost every board. Resistors act like faucets, controlling current flow. Capacitors are like tiny reservoirs, storing charge temporarily and filtering out noise. They are small and inexpensive but critical for stable circuit operation.

Inductors and Transformers

These deal with magnetic energy. Inductors resist changes in current and are often used in filtering. Transformers can step voltage up or down.

Connectors and Interface Components

These are the “gateways” for the board to communicate with the outside world. USB ports, power jacks, and pin headers are common examples. They need to be mechanically robust to withstand repeated mating cycles.

Special-Function Components

Depending on the application, there might also be sensors (for temperature, light, pressure), relays (controlling high current with a small signal), displays, buzzers, and more.

In the manufacturing environment of Shenzhen, we handle projects from around the globe daily. When it comes to board components, several common yet important situations arise:

“Correct on Paper” Doesn’t Always Mean “Works Well in Practice”

A design might call for a “10uF capacitor,” but dozens of options exist from different brands, series, and sizes. Some are better for high temperatures, others for high-frequency applications, some have longer lifespans. The choice often depends on the product’s actual end-use environment.

Supply Chain Reliability

A complex board might use over a hundred different components. A shortage or price spike for any single one can delay the entire project or inflate costs. An experienced manufacturing partner will often suggest having one or two alternative parts ready or pre-assessing supply risks for critical components.

Details in Design for Manufacturability

Component selection affects not just function but also production. For instance, choosing two resistors with nearly identical sizes but different packages might force the pick-and-place machine to change nozzles frequently, reducing efficiency. Some special packages may require more complex soldering processes.

Testing and Validation Needs

Not every component works perfectly once soldered. Before mass production, a pilot run is often necessary to validate how well the chosen parts match the design and perform under real operating conditions.

For electronics manufacturers managing multiple products, component-related matters can become quite complex. A systematic approach is often more effective than solving individual problems:

Build an Internal Knowledge Base: Document which parts performed well in past projects, which were problematic, and which suppliers were reliable. This helps teams make faster decisions in future projects.

Deep Collaboration with Your Manufacturing Partner: An experienced PCBA manufacturer (like Kaboer in Shenzhen) can provide valuable input beyond assembly—on part selection, supplier evaluation, and alternative solutions. Because we interact with a vast array of components and suppliers daily, we see a broader industry picture.

Consider Long-Term Lifecycle: If your product will be manufactured or serviced for many years, consider the long-term availability of key components. Choosing parts with long lifecycles or easy-to-find substitutes can prevent many future headaches.

Ultimately, the components on a circuit board are not just functional parts; they are carriers of product reliability, cost, and supply chain stability. Investing time to understand these “residents on the board” often saves significant time and resources later in the product development cycle.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..