Date: 2026-01-08

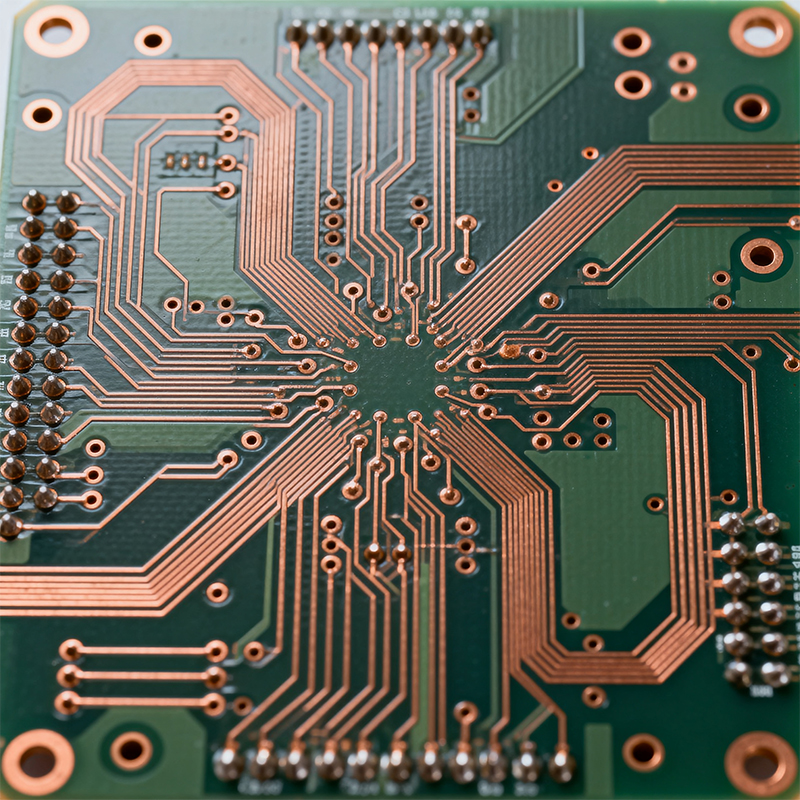

If you open up almost any electronic device—a phone, a computer, even a TV remote—you’ll see a green (or sometimes another color) board covered in fine lines and small metal dots. That board is what we call a circuit board.

Think of it as the master plan and foundation for a modern city. The copper traces on the board are the planned “roads” (circuits), responsible for carrying electrical signals precisely from one point to another. The solder pads of various sizes are the “building lots” reserved for all the electronic components—chips, capacitors, resistors.

A circuit board doesn’t start out looking like this. Its creation begins with an engineer’s design file and goes through a process that turns the virtual into the physical:

Design: An engineer uses software to draw the circuit connections, deciding where the “roads” go and where the “lots” are.

Fabrication: A factory takes the design files and uses chemical processes to etch the copper traces onto an insulating substrate (usually fiberglass), drilling the tiny holes needed for components and for connecting layers.

Finishing: The board is coated with a solder mask (that green paint) to protect the traces, and then white text and symbols (silkscreen) are printed on to help identify where components go.

Testing: The board is checked to ensure all connections are correct—no shorts, no open circuits.

At this point, a bare circuit board (PCB) is complete. But it still can’t do anything—it’s missing its “inhabitants.”

This is a crucial distinction: a bare circuit board (PCB) and an assembled circuit board (PCBA) are two very different things.

A circuit board (PCB) is like a blank city map with only the roads and empty lots drawn on it. It’s static and passive.

A circuit board (PCBA) is that same map with skyscrapers (chips installed), infrastructure (resistors, capacitors installed), and a functioning city. It’s dynamic and functional.

When you need to source “circuit boards” for your product, what you actually need are the assembled PCBAs. This assembly step requires professional equipment (like SMT pick-and-place machines) and precise processes (like reflow soldering) to ensure thousands of tiny components are placed accurately and bonded securely.

As your design moves from the screen to production, a few things are worth paying attention to when selecting a manufacturing partner:

Do They Understand Your Needs? A good partner will want to understand what your board will be used for and any special requirements for reliability or lifespan, not just provide a quote.

Is Their Process Control Reliable? Traces on boards are getting thinner, components smaller. A manufacturer’s ability to control soldering precision and consistency directly impacts the final product’s yield and long-term stability.

Is Communication Direct and Clear? During production, design tweaks and confirmations are common. If a manufacturer owns its factory (like Kaboer in Shenzhen), communication paths are often shorter and responses faster because your questions go directly to the production team, avoiding the confusion that can happen when messages are relayed through multiple layers.

The circuit board is the physical foundation of modern electronics. Its quality fundamentally determines the performance and reliability of the final product. Whether you’re designing your own or looking for a manufacturing partner, taking some time to understand what goes into that “board” is always a worthwhile investment.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..