Date: 2025-12-18

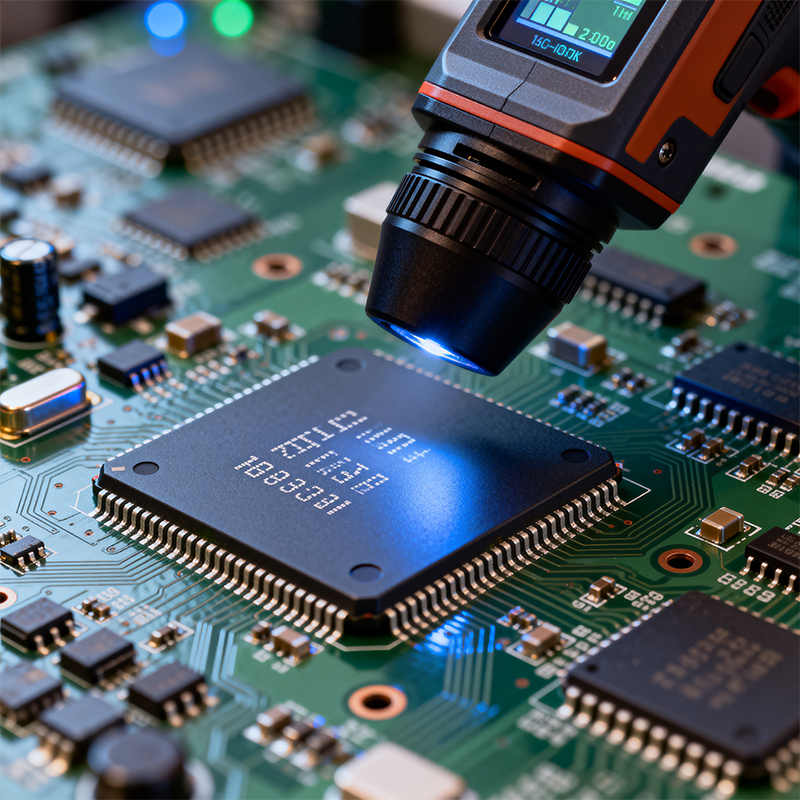

Let's be honest, have you ever stared at a tiny chip on a circuit board covered in cryptic codes like "STM32F407VET6" or "LM317T" and wondered, "What exactly is this thing?" That tiny code is its Electronic Component Identifier—the unique "name tag" or "fingerprint" that tells you everything you need to know to source, replace, and assemble it correctly.

For electronics manufacturers, especially those managing global supply chains, mastering component identification isn't just a technical detail; it's the foundation of procurement, production, and long-term product reliability. Misidentifying a single resistor can halt a production line or cause a field failure.

An Electronic Component Identifier is a standardized code—printed, laser-marked, or embedded—on an electronic component that uniquely specifies its manufacturer, type, and key electrical characteristics. It’s the critical link between the physical part on your board and the data in your Bill of Materials (BOM) and schematics.

Think of it as the VIN (Vehicle Identification Number) for electronic parts. Just as a VIN tells you a car's make, model, year, and factory, a component identifier reveals its "who, what, and how much."

The Marking Code (The "Name Tag"): This is the visible alphanumeric string on the component's body. Due to space limits on small parts, it's often a shortened or coded version.

Example: A chip marked AMS1117-3.3 is a 3.3V voltage regulator from AMS (Austria Micro Systems).

The Full Part Number (The "Official ID"): This is the complete, unambiguous number used in datasheets and procurement systems. The marking code typically points to this.

Example: The full part number might be AMS1117-3.3VTR. The suffix TR often indicates a tape-and-reel packaging format.

In PCBA manufacturing, guessing is not an option. Here’s why getting the identifier right is non-negotiable:

1. Ensuring Correct Procurement & Avoiding Counterfeits

The identifier is your primary key for sourcing. Using an incomplete or incorrect code can lead to:

Purchasing the wrong component (e.g., a 10kΩ resistor instead of a 1kΩ).

Buying from an unverified source, risking counterfeit or substandard parts that can fail in the field. Accurate identification allows you to cross-reference with manufacturer databases and authorized distributors.

2. Guaranteeing Manufacturing Quality & Yield

The pick-and-place machines on an SMT line are programmed using the component identifier. If the identifier in the machine's database doesn't match the physical part's footprint or electrical value, it can lead to:

Misplaced components.

Assembly errors.

Catastrophic failure during board testing or power-up.

3. Enabling Efficient Rework, Repair & Lifecycle Management

When a board fails or needs an upgrade, technicians rely on the identifiers to find exact replacements. This is vital for:

Long-term product support (especially in industrial, automotive, and medical fields).

Managing End-of-Life (EOL) and Last-Time-Buy (LTB) scenarios by accurately identifying which components need to be re-sourced.

4. Facilitating Troubleshooting & Failure Analysis

During debug, engineers trace signals through the schematic, which is linked to the component identifiers on the physical board. Correct identification is essential for isolating faulty components and understanding root causes of failures.

The real-world challenge is that identifiers are often miniaturized, abbreviated, or use manufacturer-specific coding systems. A code like C106DG or L15 requires cross-referencing with a datasheet or a reliable database to decode.

Integrated Circuits (ICs): Usually the most explicit (e.g., ATmega328P-PU for a Microchip microcontroller).

Resistors/Capacitors: Use alphanumeric or color-band codes for value and tolerance (e.g., 103 for a 10kΩ resistor, 106 for a 10µF capacitor).

Transistors/Diodes: Follow JEDEC or proprietary standards (e.g., 2N2222 for a common transistor, 1N4148 for a diode).

A professional assembler like Kaboer doesn't just read codes; we have systems to validate them. Here’s what a robust process looks like:

BOM Validation & Cross-Reference: Before procurement, our engineers scrutinize your BOM. We cross-reference provided part numbers with manufacturer databases to verify accuracy, suggest alternates for obsolete parts, and flag potential mismatches.

Incoming Component Verification: Upon receipt, key components are checked against purchase orders. We can verify markings and, for critical parts, use advanced tools to spot check authenticity.

SMT Programming Accuracy: Our pick-and-place machines are loaded with verified component libraries where the identifier links directly to the correct footprint, tape width, and placement parameters.

Traceability: For high-reliability builds, we can maintain lot-code traceability, linking the component identifiers on your finished board back to specific manufacturing batches.

At Kaboer, based in Shenzhen—the heart of global electronics sourcing—we deal with the reality of component identification every single day. We understand that the gap between a part number on a screen and the correct physical part on your board is where manufacturing risks are managed or multiplied.

Our value lies in applying rigorous processes to close that gap. From intelligent BOM review to disciplined warehouse management and precise machine programming, we ensure that the components specified in your design are the exact ones assembled. In a world of complex global supply chains and microscopic markings, this disciplined focus on the fundamentals is what delivers the reliability your product deserves.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..