Date: 2025-12-22

Electronics Manufacturing Services represent a comprehensive suite of solutions provided by specialized companies to handle the entire product realization journey for original equipment manufacturers (OEMs). EMS providers transform electronic designs into finished, tested, and ready-to-ship products through a vertically integrated approach that typically includes:

Design & Engineering Support: DFM/DFT analysis, prototyping, and design optimization

Supply Chain Management: Global component sourcing, procurement, and inventory management

Advanced Manufacturing: PCB fabrication, SMT assembly, through-hole assembly, box build

Testing & Quality Assurance: In-circuit testing, functional testing, environmental stress screening

After-Market Services: Repair, refurbishment, and end-of-life management

The rise of EMS providers reflects fundamental shifts in global electronics production. Rather than maintaining capital-intensive manufacturing facilities, OEMs increasingly partner with specialized manufacturers to gain:

Cost Efficiency and Capital Optimization: By outsourcing manufacturing, companies avoid massive investments in factory infrastructure, equipment, and specialized labor training, converting fixed costs into variable ones.

Access to Advanced Technology and Expertise: EMS providers continuously invest in state-of-the-art equipment and process expertise across multiple technologies, from conventional SMT to advanced packaging like SiP and microelectronics.

Supply Chain Resilience and Risk Mitigation: Professional EMS firms have established networks with global component suppliers, alternative sourcing strategies, and sophisticated inventory management systems to navigate volatile markets.

Accelerated Time-to-Market: An integrated EMS partner can seamlessly transition products from prototyping through volume production, eliminating handoff delays between different vendors.

Focus on Core Competencies: OEMs can concentrate resources on design innovation, marketing, and customer relationships while relying on manufacturing experts for production excellence.

When selecting an electronics manufacturing services provider, brands should assess capabilities across several critical dimensions:

The most valuable EMS partners engage early in the product development cycle. Key capabilities include:

Design for Manufacturing (DFM) Analysis: Identifying and resolving potential production issues before tooling begins

Design for Test (DFT) Implementation: Ensuring products can be efficiently and thoroughly validated

New Product Introduction (NPI) Process: Structured methodology for transitioning designs from prototype to production

Failure Analysis and Root Cause Investigation: Technical expertise to diagnose and resolve field issues

Evaluate both technological breadth and depth:

SMT Capabilities: Precision handling of components from 01005 size to complex BGAs, with appropriate inspection systems (SPI, AOI, X-ray)

Mixed Technology Assembly: Ability to combine SMT, through-hole, press-fit, and conformal coating processes

Box Build/System Integration: Final assembly, cabling, and mechanical integration capabilities

Scalability: Infrastructure to support both low-volume/high-mix and high-volume production

In today's environment, supply chain competence is non-negotiable:

Component Sourcing Networks: Established relationships with authorized distributors and direct manufacturer partnerships

Counterfeit Mitigation: Rigorous component verification and traceability processes

Inventory Management: Strategic safety stock programs and just-in-time delivery capabilities

Alternate Sourcing Strategies: Qualification of equivalent components to mitigate shortages

Certifications: ISO 9001, IATF 16949 (automotive), ISO 13485 (medical), AS9100 (aerospace)

Process Control: Statistical process control, continuous improvement programs

Traceability: Component-level tracking through full assembly history

Industry Standards: Adherence to IPC standards for workmanship and reliability

Lean Manufacturing Principles: Waste reduction and efficiency optimization

Digital Transformation: Industry 4.0 integration, data analytics, and smart factory capabilities

Sustainability Initiatives: Environmental compliance (RoHS, REACH), energy efficiency, and circular economy practices

Electronics manufacturing services providers are navigating several complex industry dynamics:

Supply Chain Volatility: Component shortages, extended lead times, and allocation challenges have become persistent issues requiring sophisticated mitigation strategies.

Geopolitical Considerations: Tariffs, trade policies, and regionalization of supply chains are forcing reevaluation of manufacturing footprints and sourcing strategies.

Technological Complexity: Increasing miniaturization, higher-speed designs, and advanced packaging technologies demand continuous process innovation and equipment upgrades.

Sustainability Requirements: Growing regulatory and consumer pressure for environmentally responsible manufacturing, including carbon footprint reduction and circular economy implementation.

Labor Market Dynamics: Attracting and retaining skilled technicians and engineers in competitive global markets.

Leading electronics manufacturing services providers are implementing digital transformation initiatives:

Smart Factory Implementation: IoT-enabled equipment providing real-time production data and predictive maintenance capabilities.

Digital Twin Technology: Virtual representations of manufacturing processes for optimization and simulation before physical implementation.

Advanced Analytics: Machine learning applications for quality prediction, yield optimization, and process improvement.

Supply Chain Visibility: Blockchain and other technologies for enhanced traceability and transparency across complex global networks.

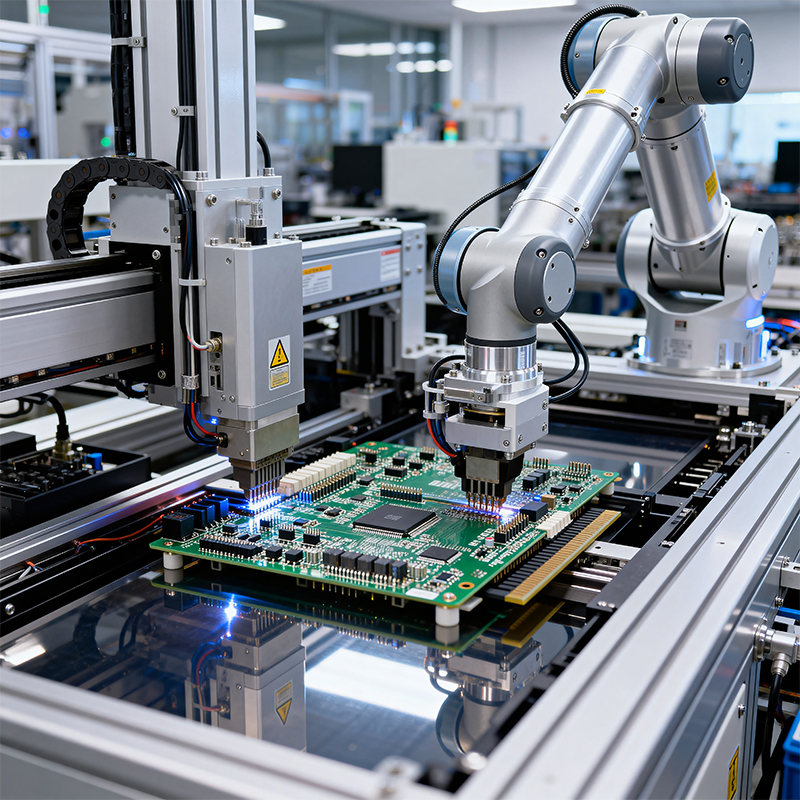

Automation and Robotics: Increasing implementation of collaborative robots and automated material handling systems.

In this complex landscape, Kaboer delivers comprehensive electronics manufacturing services from our advanced facility in Shenzhen, China. Our approach is built on integrating deep technical expertise with operational excellence to serve global electronics brands.

End-to-End Product Realization: We manage the complete journey from initial design review through volume production and after-market support. Our services include:

Engineering Services: DFM/DFT analysis, prototyping, and testing protocol development

Supply Chain Solutions: Component sourcing, procurement, and inventory management with rigorous quality verification

Advanced Manufacturing: State-of-the-art SMT lines, through-hole assembly, conformal coating, and final system integration

Quality Assurance: Comprehensive testing from in-circuit to functional validation, with full traceability documentation

Industry-Specific Expertise: We have developed specialized knowledge and processes for:

Consumer Electronics: High-volume manufacturing with rigorous cost optimization

Industrial IoT: Robust designs for challenging environments with extended lifecycle requirements

Telecommunications: High-speed and RF design manufacturing with signal integrity focus

Automotive Electronics: Adherence to IATF 16949 standards and automotive-grade reliability requirements

Operational Excellence Framework: Our manufacturing approach incorporates:

Lean Principles: Continuous improvement programs focused on waste reduction and efficiency enhancement

Quality Management: ISO 9001 certified systems with statistical process control and rigorous corrective action processes

Technology Investment: Regular upgrades to manufacturing equipment and inspection technologies

Talent Development: Comprehensive training programs for technical staff and engineers

Global Partnership Mindset: We structure engagements as true collaborations, with:

Transparent Communication: Regular reporting, shared metrics, and aligned objectives

Flexible Engagement Models: Support for turnkey, consignment, or hybrid business models

Cultural Alignment: Experience working with international teams across time zones and languages

Risk Sharing: Collaborative approach to navigating supply chain and market challenges

Electronics manufacturing services will continue evolving in response to several key trends:

Increased Regionalization: Growing emphasis on regional supply chains and manufacturing footprints to improve resilience and reduce logistical risks.

Advanced Automation: Wider adoption of AI-driven quality systems, autonomous material handling, and adaptive manufacturing processes.

Sustainability Integration: Deeper implementation of circular economy principles, carbon-neutral manufacturing, and sustainable material usage.

Service Expansion: EMS providers offering more comprehensive services including product design, software integration, and after-market support.

Digital Thread Implementation: Complete digital integration from design through manufacturing to field performance data.

Selecting the right electronics manufacturing services partner is one of the most consequential decisions an electronics company makes. The ideal provider should offer:

Technical Alignment: Capabilities matched to your specific product requirements and industry standards.

Cultural Compatibility: Communication style and business approach that aligns with your organization.

Strategic Vision: Forward-looking perspective on technology, sustainability, and market evolution.

Proven Track Record: Demonstrated success with similar products and industries.

Financial Stability: Strong balance sheet and long-term viability as a manufacturing partner.

Modern electronics manufacturing services represent far more than simple production outsourcing. They encompass a strategic partnership that integrates design expertise, supply chain mastery, manufacturing excellence, and quality assurance into a cohesive framework for product success.

In an increasingly complex global landscape, the right EMS partnership provides not just manufacturing capacity, but competitive advantage through accelerated innovation, improved quality, reduced risk, and optimized total cost. Companies that effectively leverage these partnerships can focus their resources on core competencies while accessing world-class manufacturing capabilities.

For electronics brands seeking to navigate today's challenges while building tomorrow's innovations, a strategic approach to electronics manufacturing services selection and partnership development represents one of the most impactful investments in future success.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..