Date: 2025-08-03

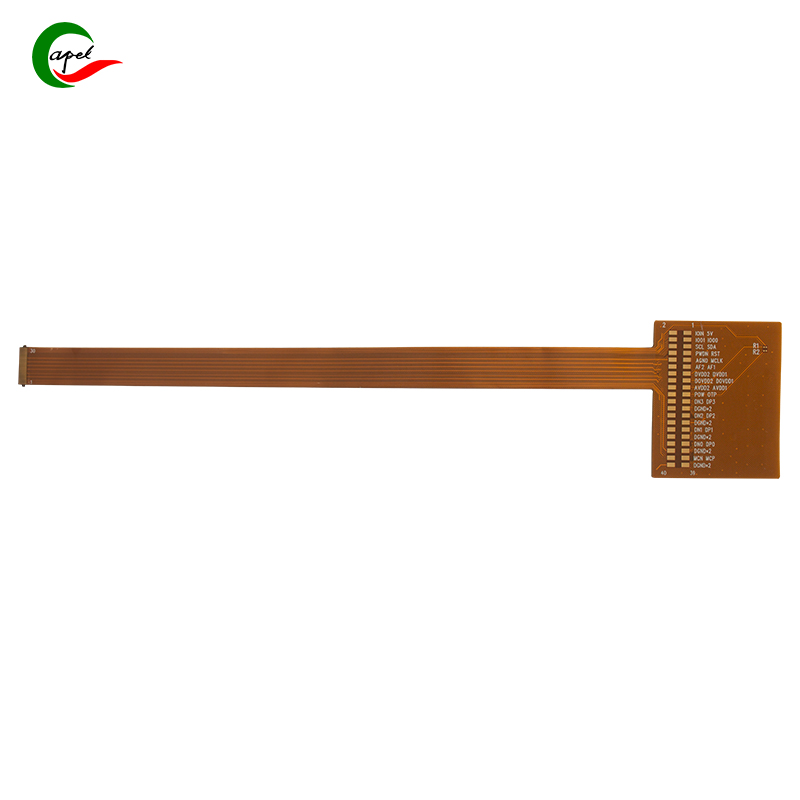

From Bulky to Bendable: How FPCs Are Changing Electronics Forever

Remember when phones were bricks, laptops weighed 10 pounds, and "wearable tech" meant a calculator watch? Those days are gone—thanks to flexible printed circuits (FPCs), the ultra-thin, bendable tech inside today’s most advanced devices.

But what makes FPCs so revolutionary? And why are they suddenly everywhere—from foldable phones to medical implants? Let’s break it down.

Traditional rigid PCBs worked fine for decades—until we demanded thinner, lighter, and more durable electronics. That’s where FPCs shine:

✅ Bend Without Breaking – Made with materials like polyimide (PI), FPCs can fold 100,000+ times (perfect for foldable phones).

✅ Save Space – A single FPC can replace multiple rigid boards, slashing device size by up to 50% (hello, AirPods!).

✅ Fit Anywhere – Engineers now design circuits that twist, curve, and flex—unlocking innovations like rollable TVs and smart clothing.

Samsung Galaxy Z Fold – Its hinge relies on ultra-durable FPCs that bend like a book.

Apple Watch – FPCs pack sensors into a band that moves with your wrist.

Stick-on Health Monitors – FPC-based patches track heart rate, glucose, and more—without bulky wires.

Implantable Devices – Pacemakers now use flexible circuits to survive years of heartbeats.

Self-Driving Cars – FPCs connect cameras and radar in tight spaces.

5G Smartphones – Next-gen FPCs (using LCP materials) boost signal speed with near-zero interference.

🔮Stretchable Electronics – Imagine a smart bandage that flexes with your skin.

🔮Eco-Friendly FPCs – Biodegradable circuits could reduce e-waste.

🔮AI + Flexible Tech – Foldable robots? Self-morphing gadgets? The possibilities are wild.

Flexible PCBs aren’t just a trend—they’re rewiring the future of tech. As devices get smaller, smarter, and more adaptable, FPCs will keep them running smoothly—no matter how much they bend.

Want to leverage FPCs for your next project? [Contact us] to build cutting-edge flexible circuits that outperform the competition.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..