Date: 2025-08-03

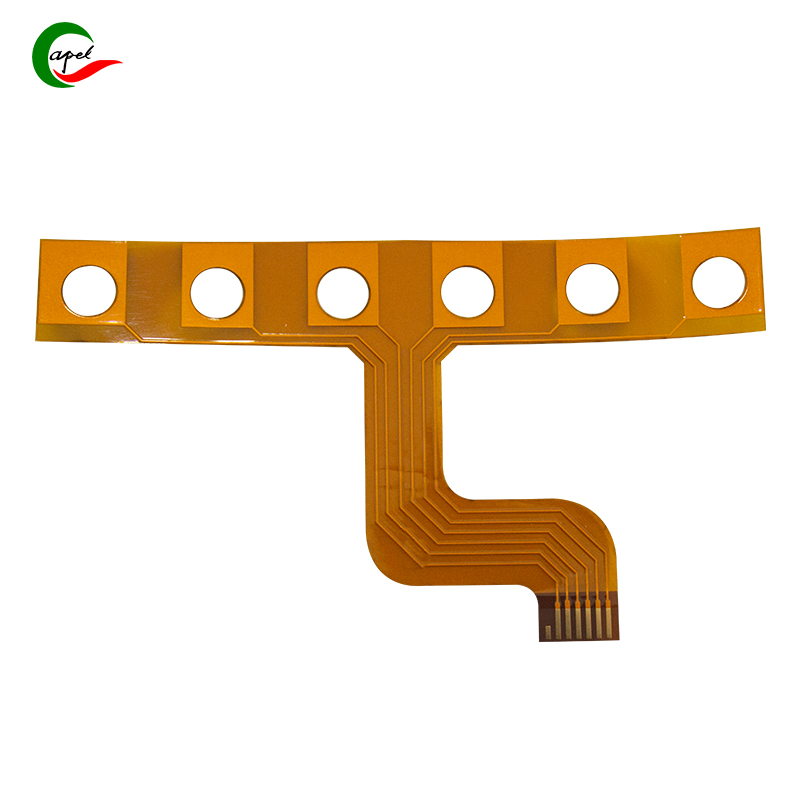

Every time you unfold your smartphone or check your smartwatch, you're relying on engineering marvels thinner than a human hair. Flexible printed circuits (FPCs) with line widths under 50 microns (that's 0.05mm!) make today's sleekest gadgets possible. But here's the shocking truth: producing these microscopic circuits is harder than building a Swiss watch. A single dust particle or 5-micron error can ruin an entire batch. So how do manufacturers achieve this microscopic precision at scale? Let's pull back the curtain.

Working at the Edge of Physics

Copper traces thinner than spider silk (9μm)

Tolerances tighter than surgical instruments (±2μm)

Cleaner than hospital operating rooms (Class 1000 cleanrooms)

The Enemies of Precision

Dust particles (a single speck can cause shorts)

Temperature fluctuations (1°C change alters etching)

Material imperfections (even atomic-level defects matter)

Why This Matters to You

30% of early smartwatch failures traced to FPC defects

Foldable phone returns drop 50% with better line control

Medical implants demand zero-defect circuits

Copper Thinner Than Your Expectations

Rolled copper foil at 6μm thickness (vs standard 18μm)

Smoother than electrolytic copper - reduces etching errors by 40%

Flawless Plastic Backbones

Polyimide films with laser-measured flatness

Adhesiveless bonding eliminates microscopic bumps

Real-World Impact:

Apple Watch's ECG sensors use 25μm traces made possible by these materials

Laser Direct Imaging (LDI)

UV lasers "draw" circuits with 1μm accuracy

Eliminates mask alignment errors

5x more precise than traditional methods

Liquid Photoresist Magic

Flows like nano-scale paint into perfect layers

Cures with edges sharper than a razor

Enables 20μm lines with 1:1 spacing

Manufacturing Reality:

Samsung's foldable phones require this precision for their hinge circuits

Acid Etching Science

Cupric chloride baths at precisely 28°C

Computer-controlled spray nozzles (0.1mm wide)

Dual-stage process prevents over-etching

Why It Matters

A 2μm over-etch can increase resistance by 15%

Under-etching causes 60% of fine-line short circuits

AI-Powered Microscopes

5μm/pixel cameras scan every square millimeter

Machine learning spots defects human eyes miss

3D lasers measure edge roughness down to 1μm

SEM Spot Checks

Electron microscopes verify cross-sections

Catches hidden threats like grain exposure

Only 1 in 10,000 panels fails final inspection

10μm Lines Coming (for next-gen AR glasses)

Self-Healing Circuits (repairing minor defects automatically)

AI Process Control (predicting errors before they happen)

That seamless fold in your phone? The reliable heartbeat monitor in your watch? They exist because teams of materials scientists, optical engineers, and manufacturing experts treat every micron as precious. In the invisible world of fine-line FPCs, precision isn't just about measurements—it's about making technology we can trust with our daily lives.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..