Date: 2025-10-24

If you're designing compact electronics, you've likely faced this frustrating reality: your components keep getting smaller, but your circuit board remains a stubborn obstacle to true miniaturization. I've been there myself - staring at a CAD model, wondering how to fit everything into that tiny enclosure.

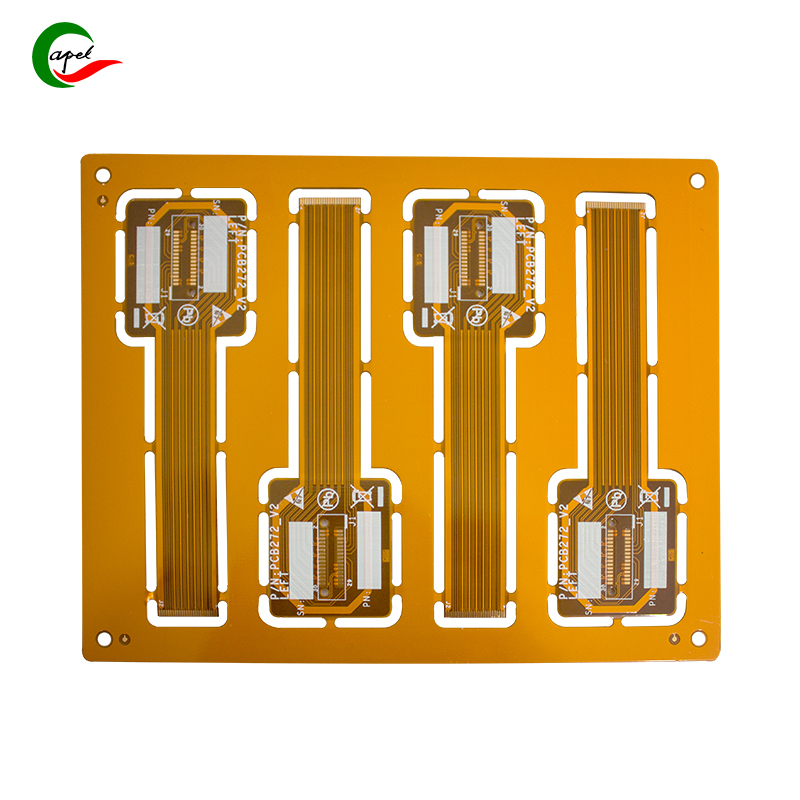

The breakthrough came when we stopped treating the circuit board as a rigid platform and started seeing it as a flexible interconnect system. Here's what I've learned about making flexible PCBs work in real-world applications.

Let's be honest about traditional PCBs - they're holding us back. In my work on wearable medical sensors, I consistently found rigid boards creating three major headaches:

First, they waste precious space. That 1.6mm thickness might not sound like much, but in a device that's only 8mm thick total, you're sacrificing 20% of your volume to the board itself.

Second, they break. I've seen too many field returns where subtle daily movements - the flex of a wrist, the impact of a drop - caused hairline cracks in rigid boards.

Third, they limit design creativity. When your circuit board must be flat, your product usually ends up boxy and generic-looking.

The transition to flexible circuits isn't just about bending - it's about rethinking electronic assembly. Here are the practical benefits I've documented:

Space efficiency that changes everything

We recently redesigned a fitness tracker using a 0.2mm flexible PCB instead of a 1.2mm rigid board. The result? We gained enough space to increase battery capacity by 30% without changing the external dimensions.

Reliability that surprises people

Properly designed flexible circuits can withstand bending cycles that would destroy rigid boards. One of our industrial sensors uses a flex circuit that survives 50,000 bend cycles - something impossible with FR-4.

Design freedom you have to experience

The best part? You're no longer constrained by flat surfaces. We've created circuits that wrap around batteries, snake through narrow channels, and conform to curved surfaces.

Through trial and error, I've developed some key principles for successful flexible PCB implementation:

Choose materials based on actual requirements

Don't automatically go for the thinnest option. For dynamic flexing applications, we use 50μm polyimide. For static applications where space is critical, we'll use 25μm.

Work with your manufacturer early

The biggest mistakes happen when engineers design in isolation. Bring your PCB supplier into the conversation during the schematic phase. They'll catch potential manufacturing issues before they become costly redesigns.

Test beyond the spec sheet

We always perform three critical tests that many overlook:

Thermal cycling with the board in its flexed position

Vibration testing while powered

Real-world mechanical fatigue testing

In a recent smartwatch project, moving to flexible PCBs allowed us to reduce the main board area by 40% while improving water resistance. The flexible connections between modules eliminated connector failure - previously our number one warranty issue.

For a miniature drone project, using a rigid-flex design let us place components in previously unusable spaces, reducing the overall weight by 15% - a massive improvement in flight time.

Switching to flexible PCBs requires changing your design mindset, but the payoff is substantial. You'll gain space, improve reliability, and unlock design options that simply aren't possible with rigid boards.

The key is starting with a clear understanding of your mechanical requirements and working closely with experienced manufacturing partners. Done right, flexible PCBs can transform your compact electronic designs from compromised to exceptional.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..