Date: 2025-10-24

If you're designing a foldable, a multi-screen laptop, or a next-gen automotive display, you already know the biggest challenge. It's not the processor or the screen technology. It's the internal wiring.

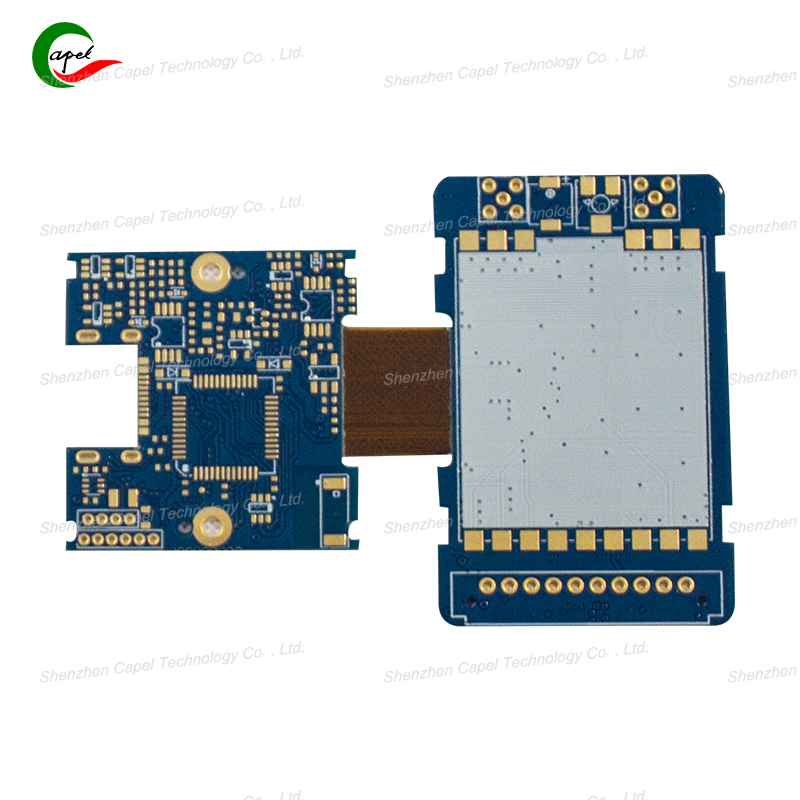

That nest of cables and board-to-board connectors is the root cause of your latency, reliability, and thickness issues. As a specialist in Rigid-Flex PCBs, we provide the escape route. We help you replace that clunky, failure-prone assembly with a single, integrated interconnect that is faster, tougher, and more space-efficient.

Let's be blunt about what traditional interconnects are costing your design:

The Lag: Every connector between your main board and display is a toll booth on a data highway. It adds milliseconds of delay, creating that infuriating stutter when a user switches screens. This isn't a software issue; it's a physical one.

The Bulk: In a world where every millimeter counts, a cable harness is your worst enemy. It forces thicker hinges and steals precious volume from your battery. We've seen designs where the wiring alone added over 1mm to the device's z-height.

The Reliability Time Bomb: Connectors loosen over time. Cables fatigue with every fold, twist, and vibration. These aren't potential failures; they are probable failures. They lead to intermittent black screens and become your number one cause of warranty returns.

We don't just sell boards; we sell a more elegant way to build. Here’s how our Rigid-Flex PCBs directly solve the issues above:

We Eliminate the Lag by Eliminating the Bottlenecks.

By creating a unified circuit from your main board to your displays, we remove the connectors that cause signal degradation. The result? We consistently achieve sub-3ms signal transmission in multi-screen setups. That's the difference between a "good enough" prototype and a "wow" product that feels seamless.

We Give You Back Your Space.

A flexible circuit is incredibly thin. We can route a critical display link through a 0.5mm hinge gap that a cable could never fit through. One of our clients, a laptop manufacturer, used this reclaimed space to increase their battery capacity by 15% without changing their industrial design. That's a powerful market advantage.

We Build Inherently More Reliable Products.

Without connectors to shake loose, and with flex circuits rated for 200,000+ dynamic bends, the entire device becomes more robust. For an automotive client, switching to our Rigid-Flex solution dropped screen-related field failures by over 70%. That's not just a spec—it's peace of mind.

A successful Rigid-Flex project isn't magic; it's about collaboration. Here's the simple framework we use with our clients:

Involve Us Early. The biggest mistakes happen when the interconnect is an afterthought. Send us your early mechanical drawings and block diagrams. The sooner we're involved, the more value we can add.

Define the Bend. Tell us exactly how and where the board will flex. Is it a daily fold? A one-time install bend? This determines everything from material selection to copper type.

Be Clear on Your Signal Needs. What's your data rate? Is EMI a major concern? This guides our stack-up and shielding recommendations.

We'll handle the complex part: selecting the right materials (be it standard PI or high-performance LCP), designing stress-resistant transitions, and manufacturing to the tightest tolerances with 100% electrical testing.

Don't just take our word for it. The results our clients see speak for themselves:

A foldable phone maker reduced their hinge thickness by 1.2mm using our solution.

An automotive tier-1 supplier qualified our boards for a 10-year vehicle lifespan.

A tablet manufacturer cut their assembly time by 25% by eliminating multiple connectors.

Your multi-screen design deserves a foundation that matches its ambition. Ditch the cables and let's build something better.

Ready to design out the compromises? Contact our engineering team for a confidential design review.

related link:

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..