To become a qualified Flexible PCB (FPCB) manufacturer, the core lies in building "end-to-end capabilities encompassing reliable technology, controllable quality, adaptive production capacity, and professional services." This requires not only meeting high industry standards such as IPC-6012F and IPC-A-600F but also accurately addressing customized needs across consumer electronics, automotive, medical, and other scenarios. With deep expertise in FPCB manufacturing, Caboer adheres to six core pillars, translating "qualification" into tangible, verifiable brand strength:

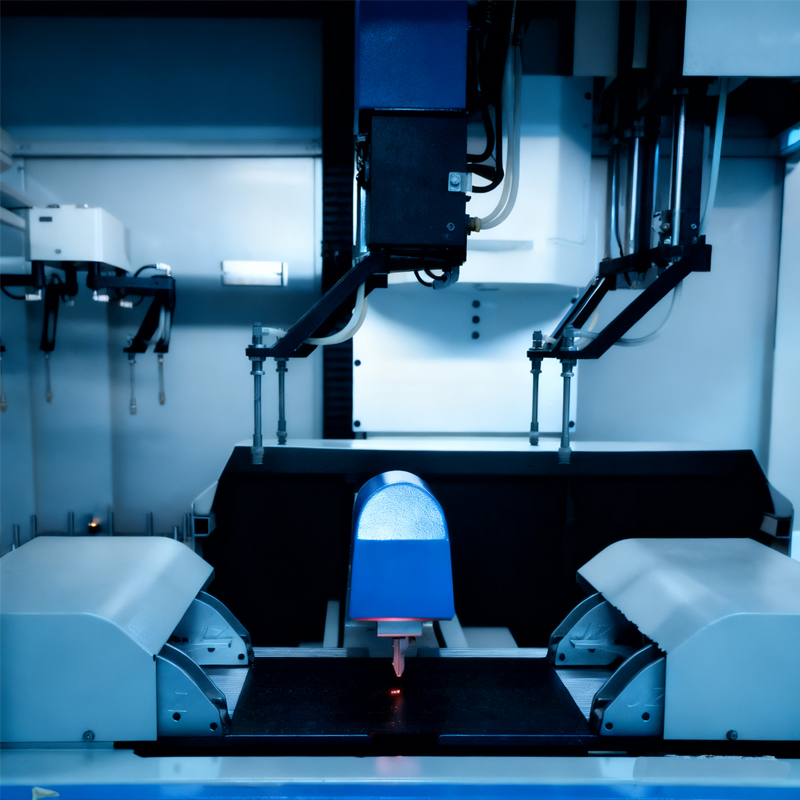

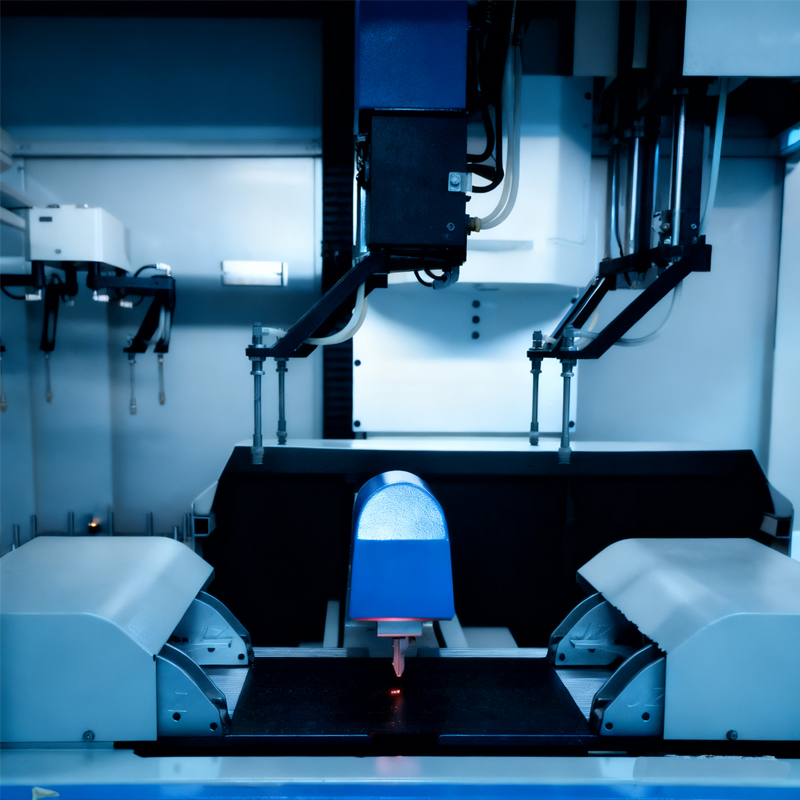

The precision and reliability of FPCB manufacturing start with in-depth mastery of core technologies and advanced equipment—non-negotiables that Caboer strictly upholds:

Caboer has fully optimized three critical links: circuit formation (photolithography + etching), interlayer interconnection (lamination + via metallization), and flexibility assurance (material selection + bending life optimization). Key achievements include:

-

Routine line width/line spacing ≤20μm (as low as 10μm for precision scenarios);

-

Interlayer alignment deviation controlled within ±3μm;

-

Dynamic bending life ≥1 million cycles for high-end electronic devices.

Additionally, Caboer flexibly supports production processes such as single/double/multi-layer FPCB (up to 20 layers), adhesive/adhesiveless structures, and rigid-flex PCBs, seamlessly adapting to diverse flexibility and density requirements.

Rejecting "workshop-style production," Caboer is fully equipped with industry-leading precision equipment:

-

Circuit Formation: LDI laser direct imaging machines (alignment accuracy ±2μm) and acid etching lines with undercut control for precise circuit patterning;

-

Interlayer Processing: Vacuum autoclaves (vacuum degree ≤10Pa) and UV laser drilling machines (hole diameter ≥50μm, position accuracy ±5μm) to ensure tight interlayer bonding and via precision;

-

Inspection Equipment: AOI (Automatic Optical Inspection) machines (resolution ≥10μm), 100% coverage flying probe testers, X-ray interlayer inspectors, and bending life testers—enabling full-cycle precision control from production to delivery.

Caboer maintains a strict qualified supplier list, sourcing core materials (PI/PET base films, RACu/EDCu foils, adhesives) exclusively from global renowned brands such as DuPont, Toray, and Nan Ya. All incoming materials undergo 100% inspection for key indicators (thickness tolerance, temperature resistance, adhesion) to eliminate defects at the source. Leveraging extensive scenario-specific experience, Caboer provides tailored material recommendations:

FPCBs are widely used in precision electronics, so "zero-defect quality" is Caboer’s core pursuit. A full-cycle quality control (QMS) system is implemented from raw materials to finished products:

-

Incoming Quality Control (IQC): 100% inspection of base films, copper foils, and auxiliary materials; unqualified materials are rejected to eliminate source risks;

-

In-Process Quality Control (IPQC): First-article inspection and scheduled patrols at critical processes (photolithography, etching, lamination, drilling); real-time recording of process parameters (temperature, pressure, time) to avoid batch defects;

-

Final Quality Control (FQC): 100% electrical testing (continuity/insulation/impedance), 100% visual inspection (AOI + manual recheck), and sampling reliability tests (thermal cycling, damp heat, bending);

-

Full-Cycle Traceability: Each batch is assigned a unique traceability code, enabling tracking of raw material batches, production equipment, operators, and test data—facilitating rapid issue localization.

Caboer holds ISO9001 (Quality Management System) and ISO14001 (Environmental Management System) certifications. For automotive electronics, it has obtained IATF16949 certification; for medical devices, ISO13485 certification. All products comply with RoHS and REACH environmental standards, providing compliant, reliable delivery guarantees for global customers.

Balancing "customization flexibility" and "mass production stability" is Caboer’s core service capability:

Caboer operates multiple modular production lines, enabling quick switching between small-batch customization (≤1000 pieces) and mass production (≥100,000 pieces). It accommodates both high-end custom orders and large-scale production, eliminating the pain point of "being unable to handle large orders or unwilling to accept small ones." A 20%-30% production capacity buffer is reserved to handle urgent orders or peak demand.

-

Prototype Lead Time: 3-5 working days for standard single/double-layer FPCBs; 5-7 working days for multi-layer FPCBs—shortening customer R&D cycles;

-

Mass Production Lead Time: 15-25 working days for batches ≥10,000 pieces (including scheduling, production, inspection, and packaging);

-

Supply Chain Collaboration: Emergency supply agreements and safety stock with core material suppliers to avoid delivery delays due to material shortages.

The FPCB industry is dominated by customization. Caboer acts not just as a manufacturer but as a "technical partner" to customers:

A professional Design for Manufacturability (DFM) engineering team provides free FPCB design optimization suggestions (wiring rationality, laminated structure, bending area reinforcement) to avoid "production difficulties or product failure caused by poor design." Detailed DFM reports are issued, specifying manufacturability parameters (minimum line width, hole diameter, pad size).

-

Parameter Customization: Adjustable line width/line spacing, layer count, thickness, surface finish (ENIG/tin plating/OSP), and forming shape (irregular cutting);

-

Scenario-Specific Customization: Specialized R&D for high-temperature (≥150℃), high-bending (1 million cycles), and biocompatible (medical) requirements—accompanied by comprehensive reliability test reports (salt spray, damp heat, bending life).

A dedicated after-sales team ensures 24-hour response and 48-hour solution provision for customer feedback (e.g., performance issues, delivery delays). For confirmed production-related issues, free replacement/refund is offered, along with rectification reports to prevent recurrence.

Caboer strictly protects customer design drawings and intellectual property, abides by industry patents, and upholds business integrity. It adopts halogen-free materials and low-VOC processes, with wastewater and waste gas treated to meet emission standards—achieving green production in line with national environmental policies.

Recognizing the rapid technological iteration in the FPCB industry, Caboer allocates 5%-10% of annual revenue to R&D, focusing on three key areas:

-

Process Optimization: Pursuing 5μm/5μm precision wiring and reducing production costs;

-

New Material Application: Testing advanced PI base films and eco-friendly adhesives to enhance bending life and temperature resistance;

-

Scenario Expansion: Specialized R&D of high-reliability FPCBs for autonomous driving, wearable medical devices, and aerospace—leading industry technological trends.

-

Process Engineers: Proficient in full-cycle FPCB processes, capable of resolving technical issues (uneven etching, interlayer bubbles, via conductivity);

-

Quality Engineers: Deeply familiar with IPC standards, able to develop custom inspection plans and accurately assess product qualification;

-

Sales Engineers: Combining technical expertise and market insight to accurately convey customer needs and coordinate internal resources for seamless demand-production alignment.

-

New Employee Training: Mandatory training in processes, quality, and safety—only qualified employees are allowed to work;

-

Regular Skill Enhancement: Routine training on new technologies and standards (e.g., IPC-6012F updates, advanced equipment operation) to ensure the team’s technical capabilities keep pace with the industry.

-

Technology: Stable production of high-precision, high-reliability FPCBs for diverse scenarios;

-

Quality: ≥99.5% product qualification rate through authoritative certifications and full-cycle control;

-

Service: End-to-end support from design optimization to after-sales—becoming a trusted technical partner;

-

Capacity: Flexible adaptation to small/large orders with timely delivery;

-

Long-Term Vision: Compliant operation, sustained R&D, and alignment with industry evolution.

Caboer firmly believes that a qualified FPCB manufacturer is not just "capable of production" but a long-term win-win partner that enables customers to "deliver with confidence, cooperate with ease, and use with peace of mind." With end-to-end capabilities, Caboer empowers the flexible innovation of global electronic devices.