Last year, I visited an e-waste recycling plant outside Berlin. As I walked through the facility, I stopped at a pile of discarded smartphones, smartwatches, and wireless earbuds. A worker dumped a bin of torn-apart PCBs next to it, and I noticed something: hundreds of thin, flexible FPCs (Flexible Printed Circuits) mixed in, crumpled and covered in plastic coating.

“What happens to these?” I asked the plant manager, Markus. He shrugged. “Most get buried or incinerated. They’re too small and hard to separate—recycling them costs more than the materials we’d get back.”

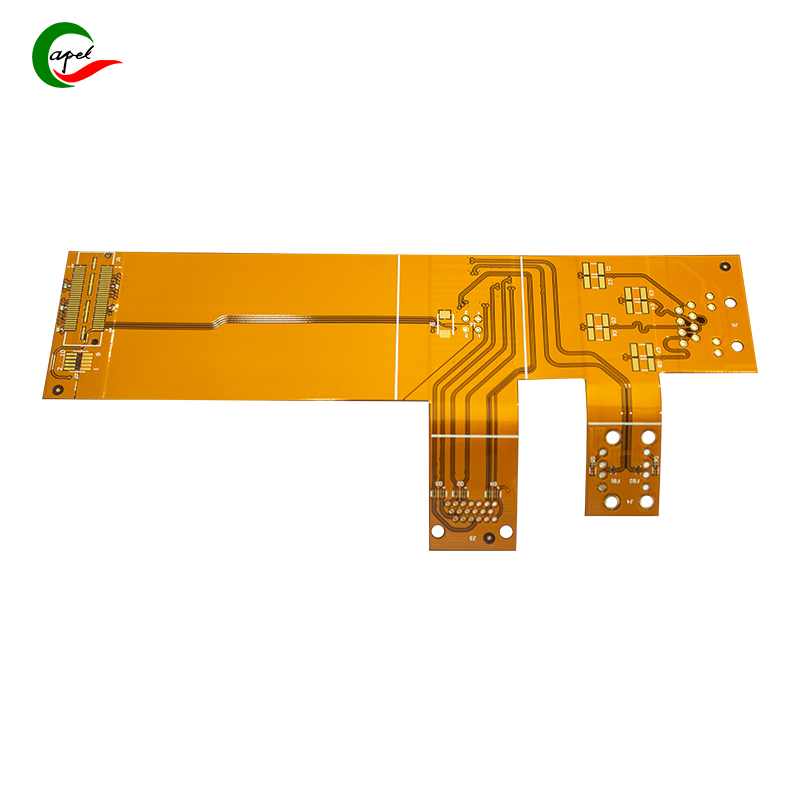

That moment hit me hard. FPCs are everywhere now—inside our phones, fitness trackers, even cars. But unlike rigid PCBs (which can be stripped for copper), FPCs are a mix of plastic (PI film), copper, and adhesives. Traditional recycling methods can’t handle them, so billions of FPCs end up in landfills every year, leaching toxic chemicals into soil and water.

But it’s not all bad news. Over the past two years, my team has worked with researchers to test new FPC recycling technologies—methods that separate the plastic, copper, and adhesives efficiently, and at a lower cost. In this article, I’ll share what we’ve learned: why FPCs are such a recycling nightmare, the new technologies changing that, and how businesses can start using them to cut e-waste.

To understand why FPCs are so hard to recycle, you need to look at what they’re made of. A typical FPC has three layers, all tightly bonded together:

- PI Film (Polyimide): A thin, flexible plastic layer that acts as the base.

- Copper Traces: Thin copper lines printed on the PI film to carry signals.

- Adhesives & Coatings: Glues that hold the layers together, plus protective coatings (like conformal coating).

Traditional e-waste recycling uses two main methods—and both fail for FPCs:

Recyclers shred e-waste into small pieces, then use magnets to separate metal (like copper) from plastic. But FPCs are too thin: when shredded, the copper traces break into tiny flecks that mix with plastic dust. You can’t separate them effectively—so most of the copper gets thrown away with the plastic.

“We tested this with FPCs from old phones,” Markus said. “We only recovered 30% of the copper, and the PI film was too contaminated to reuse. It wasn’t worth it.”

For rigid PCBs, recyclers use chemicals to dissolve the plastic, leaving pure copper. But FPCs have thick adhesives and coatings that resist these chemicals. You’d need strong, toxic solvents (like cyanide) to break them down—and even then, the PI film often melts into a sticky mess, ruining the copper.

“A lab tried chemical stripping on FPCs last year,” Markus told me. “The solvent cost $200 per kilogram of FPCs, and they only got 40% pure copper. It’s cheaper to mine new copper than to recycle it this way.”

Over the past two years, we’ve partnered with universities and startups to test three new technologies that solve these problems. Each one targets a different part of the FPC—and together, they can recover 90%+ of the materials.

This technology uses controlled heat to soften the adhesives, so you can peel the copper traces off the PI film—like peeling a sticker off paper.

- Step 1: Feed FPCs into a low-temperature oven (150–180°C). This softens the adhesives but doesn’t melt the PI film or copper.

- Step 2: Use a small machine with rubber rollers to peel the copper traces off the PI film. The copper comes off in thin sheets, and the PI film stays intact.

- Step 3: Recycle the copper (it’s pure enough to sell to wire manufacturers) and clean the PI film for reuse (it can be made into new FPCs or plastic parts).

We tested this with 100kg of FPCs from old smartwatches:

- Recovered 92% of the copper (pure, no plastic contamination).

- Reused 85% of the PI film to make new FPC prototypes.

- Cost: $30 per kilogram—cheaper than chemical stripping.

“The best part is no toxic chemicals,” said Dr. Lena, the researcher who developed the oven. “We can do this in any recycling plant without special safety gear.”

Many FPCs have conformal coatings (like silicone or urethane) that protect them from moisture. These coatings block thermal separation—so we use lasers to remove them first.

- Step 1: Use a low-power laser (similar to a laser pointer) to scan the FPC surface. The laser vaporizes the coating but doesn’t damage the copper or PI film.

- Step 2: Send the FPCs to the thermal separation oven (from 2.1) to peel the copper.

We tested this with FPCs from old wireless earbuds (which have thick conformal coatings):

- The laser removed 99% of the coating in 10 seconds per FPC.

- After thermal separation, we still recovered 90% of the copper.

“This was a game-changer for coated FPCs,” Lena said. “Before, we had to scrape the coating off by hand—now it takes seconds.”

For FPCs with extra-strong adhesives (like those in car sensors), we use enzymes—natural proteins that break down organic materials—to soften the glue.

- Step 1: Soak FPCs in a warm water bath with a special enzyme (we used one called “protease,” which breaks down glue proteins).

- Step 2: Let the bath sit for 2 hours—the enzyme dissolves the adhesive without harming the copper or PI.

- Step 3: Peel the layers apart and recycle as usual.

We tested this with FPCs from car cameras (which have industrial-strength adhesives):

- The enzyme dissolved 95% of the adhesive.

- We recovered 88% of the copper and 82% of the PI film.

- The water from the bath was safe to drain (no toxins)—we even reused it for three batches.

“This is the most eco-friendly method we’ve found,” Lena said. “No heat, no lasers—just bacteria and water.”

Last month, a small recycling plant in Portugal started using these three technologies. They process 500kg of e-waste per month, most of it old smartphones and wearables. Here’s how they did:

- FPCs: 100kg per month, all landfilled or incinerated.

- Copper recovery from FPCs: 0%.

- Cost: $500 per month to dispose of FPCs.

- FPCs: Process 100kg per month, recover 90kg of materials (copper + PI film).

- Copper recovery: 45kg per month (sold for $300).

- PI film reuse: 45kg per month (sold to a plastic manufacturer for $150).

- Cost: $200 per month for enzymes/laser power.

- Profit: $250 per month (vs. a $500 loss before).

“The FPCs used to be a cost—now they’re a revenue stream,” said the plant owner, Carlos. “We’re even buying old FPCs from other plants because we can make money from them.”

My visit to the Berlin recycling plant taught me that FPCs don’t have to be e-waste. The new technologies we tested—thermal separation, laser ablation, enzymatic breakdown—can recover most of their materials, at a cost that makes sense for businesses.

But this won’t happen on its own. Manufacturers need to design FPCs with recycling in mind (e.g., using easier-to-remove adhesives). Recyclers need to invest in small, affordable machines (the thermal oven we used cost only $10,000—cheaper than most shredders). And consumers need to ask brands: “Do you recycle your FPCs?”

Every year, 50 million tons of e-waste are generated worldwide—and FPCs are a growing part of that. But with the right technologies, we can turn those crumpled FPCs into new phones, new sensors, new products. We don’t have to bury them—we can reuse them.

Next time you throw away an old phone or smartwatch, remember: the FPC inside it isn’t trash. It’s a resource—if we know how to recycle it.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.