Last year, my team was designing a new smart watch aimed at fitness lovers. Our goal was simple: pack a heart rate sensor, GPS, and 3-day battery into a watch case just 10mm thick (thinner than a AA battery). But by week three, we hit a wall. The rigid PCB we’d used to connect the components took up so much space that the prototype ended up 14mm thick—too bulky to wear comfortably.

“We need to stop treating the PCB like a flat sheet,” our hardware designer, Javi, said, holding up the clunky prototype. “The watch case is curved—why isn’t the wiring curved too?”

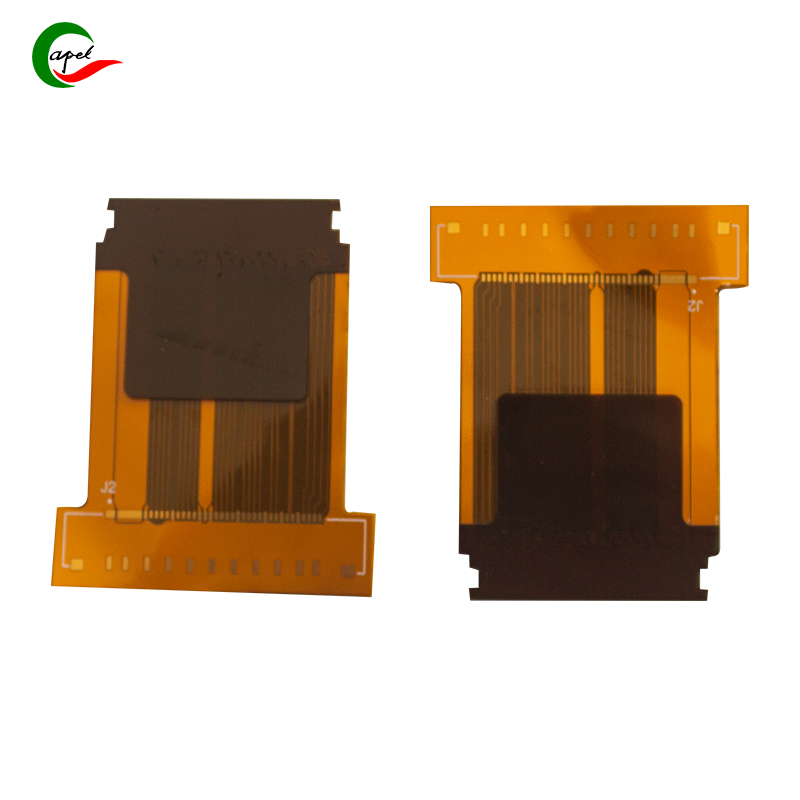

That’s when we switched to Flexible Printed Circuits (FPCs). Within a month, we’d redesigned the watch’s internal layout: the FPC snaked around the battery, hugged the curved edge of the screen, and even fit under the sensor module. The result? A 9.8mm-thick prototype that had all the features we wanted. “FPCs don’t just save space—they let you use space you didn’t know you had,” Javi said.

This experience taught us why FPCs are the backbone of modern smart watches: traditional rigid PCBs force you into a “flat, wasteful” layout, but FPCs bend, fold, and conform to the watch’s tiny, curved space. If you want a smart watch that’s thin, light, and packed with features, FPCs aren’t an option—they’re a necessity.

Smart watches are tiny—most have a case volume of just 3–5 cubic centimeters. Traditional rigid PCBs are terrible at using this space efficiently, and here’s why:

A rigid PCB is a stiff, flat board. But smart watch cases are curved to fit your wrist—so the PCB either sticks out (making the watch thicker) or leaves empty space around the edges (wasting room you could use for a bigger battery or sensor).

“Our first prototype’s rigid PCB was a rectangle that sat in the middle of the curved case,” Javi said. “We had 2mm of empty space on all sides—space we could’ve used for a larger battery, but the PCB couldn’t reach it.”

Rigid PCBs need separate wires to connect to components that aren’t on the board—like a heart rate sensor on the watch’s back or a button on the side. These wires take up space, get tangled, and require bulky connectors that eat into internal room.

“We used three thin wires to connect the rigid PCB to the heart rate sensor,” said our intern, Lila. “They took up 15% of the watch’s internal space, and we had to add a connector that was 1mm thick—enough to make the watch 0.5mm thicker than we wanted.”

To fit more components on a rigid PCB, you might use multi-layer boards—but each layer adds thickness. A 4-layer rigid PCB is 1.6mm thick, which is a huge chunk of a 10mm-thick watch’s space.

“We tried a 2-layer rigid PCB to fit the GPS module,” Javi said. “It was 1.2mm thick—12% of our total target thickness. We had to cut the battery size to fit it, and then the watch only lasted 1 day instead of 3.”

FPCs fix the space-wasting problems of rigid PCBs by being flexible, thin, and adaptable. Here are the exact techniques we used to slim down our smart watch prototype:

FPCs can bend vertically (up/down) and horizontally (left/right), so you can route them along the watch case’s curved edges—using space that rigid PCBs can’t reach.

We routed a thin FPC (0.1mm thick) along the inner curve of the watch case, from the main board near the screen to the heart rate sensor on the back. The FPC hugged the curve perfectly, using the empty space we’d wasted before. “We didn’t just save space—we used space we thought was useless,” Javi said.

Map the watch case’s curves first (use 3D scans) and design the FPC to follow those curves. Avoid sharp bends (they weaken the FPC) and use gradual curves (radius ≥1mm) instead.

Instead of using a separate rigid PCB for small components (like resistors, capacitors, or even tiny sensors), mount them directly on the FPC. This eliminates the need for wires or connectors to link the components to the main board.

We printed two 0402-sized resistors (0.4mm × 0.2mm) and a small temperature sensor directly on the FPC that connected the screen to the battery. This saved us from using a separate 0.8mm-thick mini PCB for those parts. “We freed up 8% of the watch’s space—enough to add a 10% bigger battery,” Lila said.

Stick to small, surface-mount components (0402 or 0201 size) to keep the FPC thin and flexible. Avoid heavy components (like connectors) on the flexible parts—mount those on the rigid sections of hybrid FPCs.

Most smart watch FPCs don’t need multiple layers—single-layer FPCs (one layer of PI film with traces on one side) are thin enough (0.075–0.1mm) and take up less space than multi-layer versions.

We replaced the 2-layer rigid PCB with a single-layer FPC for the main signal path. It was 0.08mm thick—15x thinner than the rigid PCB. “That one change cut the watch’s thickness by 1mm,” Javi said.

Only use multi-layer FPCs if you have to (e.g., for complex signal paths). For most smart watch features (heart rate, step counting), single-layer FPCs work perfectly.

FPCs can be folded over themselves to stack components vertically—using height instead of width or length. This is perfect for smart watches, where height (thickness) is more critical than width.

We folded a small section of the FPC over the battery, allowing us to mount the GPS module on top of the battery instead of next to it. This saved 3mm of width—enough to make the watch case 2mm narrower (more comfortable for small wrists).

Use a flexible adhesive to hold folded FPC sections in place—avoid rigid glue that might crack the FPC when the watch is worn (your wrist bends, and the FPC should too).

Instead of using loose wires to connect components, add small “branches” to the main FPC—short, flexible extensions that plug directly into sensors or buttons. This eliminates wires and bulky connectors.

We added a 5mm-long FPC branch to the main board that plugged directly into the watch’s side button. This replaced a 0.8mm-thick connector and a 2mm-long wire—saving 0.5mm of thickness and 10% of internal space.

Design branches to be as short as possible (5–10mm) to keep the FPC flexible. Test the branches for durability—they should bend 1,000+ times (simulating wrist movement) without breaking.

After using these 5 techniques, our smart watch prototype met all our goals:

- Thickness: 9.8mm (under our 10mm target).

- Battery Life: 3.2 days (we used the saved space for a bigger battery).

- Features: Heart rate sensor, GPS, and even a small blood oxygen sensor (we had extra space!).

We launched the watch 6 months later, and it quickly became a bestseller. One customer, a runner named Mia, left a review: “I’ve tried thick smart watches that hurt my wrist, but this one is so thin I forget I’m wearing it—even during long runs.”

Javi still keeps the original 14mm rigid PCB prototype on his desk. “It’s a reminder of why we use FPCs,” he said. “Without them, this watch would’ve been too bulky to sell. With them, it’s a product people love.”

Our smart watch journey taught us that in tiny devices like smart watches, space is the most valuable resource. Traditional rigid PCBs waste that resource with flat, wire-cluttered layouts—but FPCs turn waste into utility.

Whether you’re adding a bigger battery, a new sensor, or just making the watch thinner, FPCs let you do more with less space. They don’t just fit into the watch—they fit around the watch, using every curve and crevice to your advantage.

Next time you look at a slim, feature-packed smart watch, take a second to appreciate the FPC inside. You can’t see it, but it’s the reason the watch is comfortable to wear, lasts for days on a charge, and has all the features you need. And that’s the magic of FPCs in smart watches.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.