Last quarter, I was tasked with soldering FPCs (Flexible Printed Circuits) to the screens of 100 smart watches for a client. I’d soldered rigid PCBs before, so I thought it’d be easy. I grabbed my 60W soldering iron, heated up the FPC’s connector tabs, and applied the solder. Two weeks later, the client called in a panic: 80% of the watches had stopped working. When we opened one, we found the problem—cold solder joints. The solder looked like it was stuck to the FPC, but it hadn’t properly bonded to the copper traces. “You treated the FPC like a rigid PCB,” our senior technician, Mei, said. “FPCs are delicate—too much heat, too little time, and you get cold joints that fail later.”

That mistake cost the company $2,000 in replacement parts and a week of rework. But it also taught me the hard way: FPC soldering isn’t just about melting solder—it’s about balancing heat, time, and pressure to create a strong bond. Over the next month, Mei showed me her tricks, and I went from ruining batches to soldering FPCs with zero failures. This guide is for anyone struggling with FPC soldering: no fancy tools, just practical steps to avoid cold joints and keep your FPCs from desoldering.

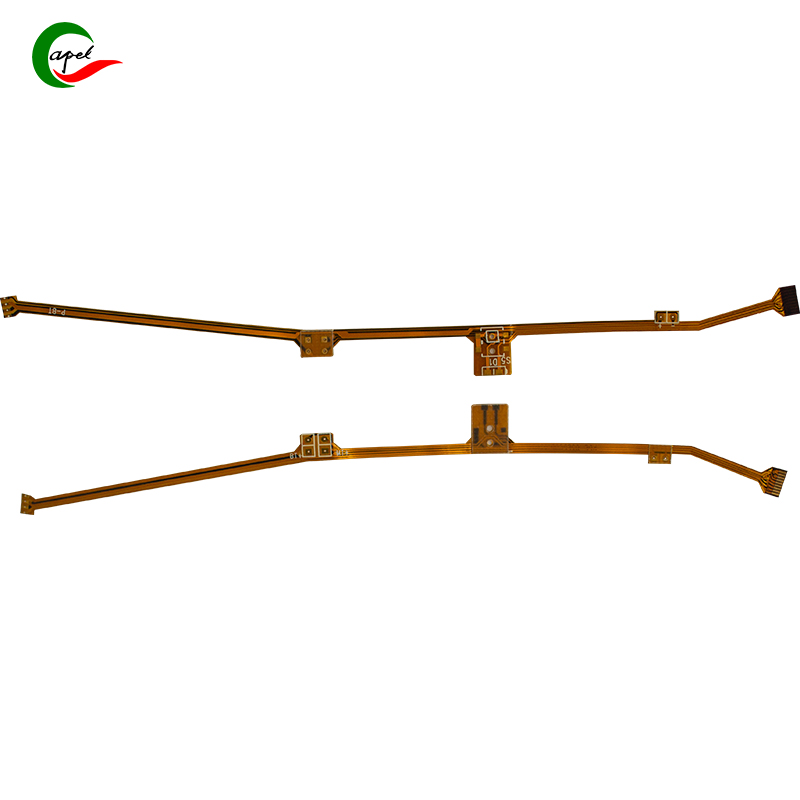

FPCs are made of thin PI film with tiny copper traces—nothing like the thick FR4 and large pads of rigid PCBs. This makes soldering tricky for three big reasons:

PI film (the flexible part of the FPC) can only handle temperatures up to 300°C for short periods. A 60W soldering iron (which heats to 400°C+) can melt the PI film in 5 seconds—ruining the FPC or creating weak joints.

“In my first batch, I used a 60W iron, and the PI film around the traces turned brown,” I said. Mei pointed out the damage: “The melted PI creates a barrier between the solder and the trace—so the solder never bonds properly. That’s why the joints failed.”

FPC traces are often 0.1mm wide—half the size of a rigid PCB pad. It’s easy to apply solder to the PI film instead of the trace, creating a “false joint” that looks good but isn’t connected.

“We found solder on the PI film in 60% of the failed watches,” Mei said. “You thought you were soldering the trace, but you were just gluing solder to the plastic. It fell off as soon as the watch was used.”

Even if you solder the FPC correctly, its flexibility can pull on the joint over time. If the joint is weak (from cold soldering), it will desolder or break when the FPC bends.

“A tester wore one of the watches for 3 days,” Mei said. “Every time they moved their wrist, the FPC bent, and the weak joint pulled apart. That’s why the watch stopped working.”

You don’t need expensive equipment to solder FPCs—just the right tools to control heat and precision. Here’s what I use now (all under $80):

-

Low-Wattage Soldering Iron (25–30W): A 25W iron heats to 280–320°C—safe for PI film and hot enough to melt solder. Avoid 60W+ irons—they’re too hot.

-

Fine-Tip Soldering Iron (0.5mm): A small tip lets you target tiny FPC traces without touching the PI film. I use a chisel-shaped tip (0.5mm wide) for better control.

-

Thin Solder (0.3–0.5mm Diameter): Thick solder (0.8mm+) is hard to apply to small traces. Thin solder lets you add just enough to make a joint.

-

Solder Flux (Rosin-Core or Liquid): Flux cleans the FPC traces and helps solder flow evenly. Use rosin-core solder (it has flux inside) for extra convenience.

-

Kapton Tape: Heat-resistant tape to hold the FPC in place and protect the PI film from accidental heat.

-

Magnifying Glass or Headlamp: FPC traces are small—you need to see exactly where you’re soldering. A headlamp frees up your hands.

-

Tweezers (Fine-Point): To hold the FPC steady without touching the traces.

Mei’s tip: “Invest in a temperature-controlled soldering iron if you can. It lets you set the heat to 280°C—no guesswork, no melted PI film.”

Follow these steps, and you’ll avoid cold joints, melted PI film, and desoldering. I use this process for every FPC I solder now:

-

Clean the Traces: Wipe the FPC’s solder pads with isopropyl alcohol (IPA) and a cotton swab. Dirt or oil on the traces will prevent solder from bonding.

-

Secure the FPC: Stick Kapton tape to the FPC’s PI film (not the traces!) to hold it flat on a workbench. If the FPC moves while soldering, you’ll miss the trace.

I used to skip cleaning the traces. The oil from my fingers created a barrier, and the solder wouldn’t stick. Now I clean every FPC—no exceptions.

-

Set the Temperature: If you have a temperature-controlled iron, set it to 280°C. If not, let a 25W iron heat up for 3–4 minutes (it will reach ~300°C—safe for PI film).

-

Tin the Tip: Melt a tiny amount of solder on the iron’s tip. This helps transfer heat to the trace and prevents the tip from sticking.

If the tip is dull, file it slightly to create a sharp edge. A sharp tip lets you target the trace without touching the PI film.

This is the most critical step—too much heat, and you melt the PI film; too little, and you get a cold joint.

-

Touch the Iron to the Trace: Place the tinned tip on the FPC trace for 1–2 seconds. You want to heat the trace, not the PI film.

-

Add Solder to the Trace (Not the Iron): Touch the end of the thin solder to the trace (not the iron tip) for 0.5–1 second. The solder will melt and flow onto the trace.

-

Remove the Solder First, Then the Iron: Pull the solder away first, then the iron. This ensures the solder stays on the trace.

-

Let It Cool: Wait 5–10 seconds for the joint to cool. Don’t touch it—hot solder can crack or pull away from the trace.

-

Shiny, smooth, and small (no blobs).

-

The solder covers the trace but doesn’t spread onto the PI film.

-

You can see the edge of the trace through the solder (no excess).

-

Dull, grainy, or lumpy (cold joint).

-

Solder spread onto the PI film (risk of melting).

-

No solder on the trace (missed the target).

A joint that looks good might still be weak. Test it with these two steps:

-

Visual Check: Use a magnifying glass to look for cracks, gaps, or solder on the PI film.

-

Tug Test: Gently pull the FPC with tweezers (not too hard!). A good joint won’t move or come loose. If it does, you have a cold joint—re-solder it.

I use a multimeter set to “continuity” to test the joint. Touch one probe to the soldered trace and the other to the FPC’s connector. If the multimeter beeps, the joint is good. If not, it’s a cold joint.

Even with practice, you might get a cold joint or a joint that desolders later. Here’s how to fix it without ruining the FPC:

-

Heat the Joint: Touch the iron to the cold joint for 1–2 seconds to reheat the solder.

-

Add a Tiny Bit of Solder: Touch the solder to the joint to refresh it. The new solder will mix with the old and create a strong bond.

-

Cool and Test: Let it cool, then test with the multimeter.

-

Clean the Trace: Use IPA to remove any old solder residue from the trace.

-

Apply Flux: Add a drop of liquid flux to the trace (flux helps the new solder stick).

-

Re-Solder: Follow the steps in Section 3.3—make sure to heat the trace first, then add solder.

-

Reinforce (Optional): If the FPC bends a lot, add a small piece of Kapton tape over the joint to reduce stress.

These are the mistakes I made most often—learn from them to keep your FPCs intact:

-

Using Too Much Heat: A 60W iron will melt PI film. Stick to 25–30W.

-

Heating the PI Film Instead of the Trace: Always target the trace—if the PI film turns brown, you’re too close.

-

Adding Too Much Solder: Blobs of solder can short nearby traces or melt the PI film. Use thin solder and add just enough.

-

Moving the FPC While Soldering: Secure the FPC with Kapton tape—movement leads to missed traces.

-

Skipping the Test: A cold joint might work for a day, but it will fail later. Always test with a multimeter.

Last month, I soldered 50 FPCs to smart watch screens using this process. Zero cold joints, zero melted PI film, and zero returns. The client sent an email saying: “These watches are holding up better than any we’ve had before. Whatever you changed—keep doing it.”

Mei smiled when she heard. “You didn’t just learn to solder FPCs,” she said. “You learned to respect them. That’s the key.”

I used to think FPC soldering was “impossible to get right”—that I’d always melt the PI film or make cold joints. But now I know it’s just about control: controlling the heat, controlling the solder, and taking the time to do it right.

For beginners, start with scrap FPCs. Practice soldering small traces until you can make a shiny joint every time. Don’t rush—speed comes with practice. And if you make a mistake, fix it instead of throwing away the FPC—most cold joints are easy to rework.

Next time you solder an FPC, remember: it’s not about being perfect. It’s about being careful. A strong joint will keep the FPC working for years— and that’s what makes all the practice worth it.