Last quarter, my team was designing a portable industrial sensor. We needed a rigid-flex PCB to save space (the sensor had to fit in a palm-sized case) and handle minor bending. When we got the first quote from our manufacturer, we froze: $12 per PCB for a 500-unit order. Our budget was only $8 per unit. “This is impossible,” our project manager, Mia, said, slamming the quote on the table. “If we can’t cut costs, we’ll have to switch back to a bulkier rigid PCB—and the sensor won’t fit the case.”

We thought rigid-flex PCBs were just “expensive by nature,” but the manufacturer’s engineer, Carlos, helped us see otherwise. “Most teams overdesign rigid-flex PCBs—adding unnecessary layers or complex features that drive up costs,” he said. Over the next three weeks, we simplified the design, adjusted materials, and renegotiated the order. The final quote? $7.80 per unit—under budget, and the sensor still fit perfectly.

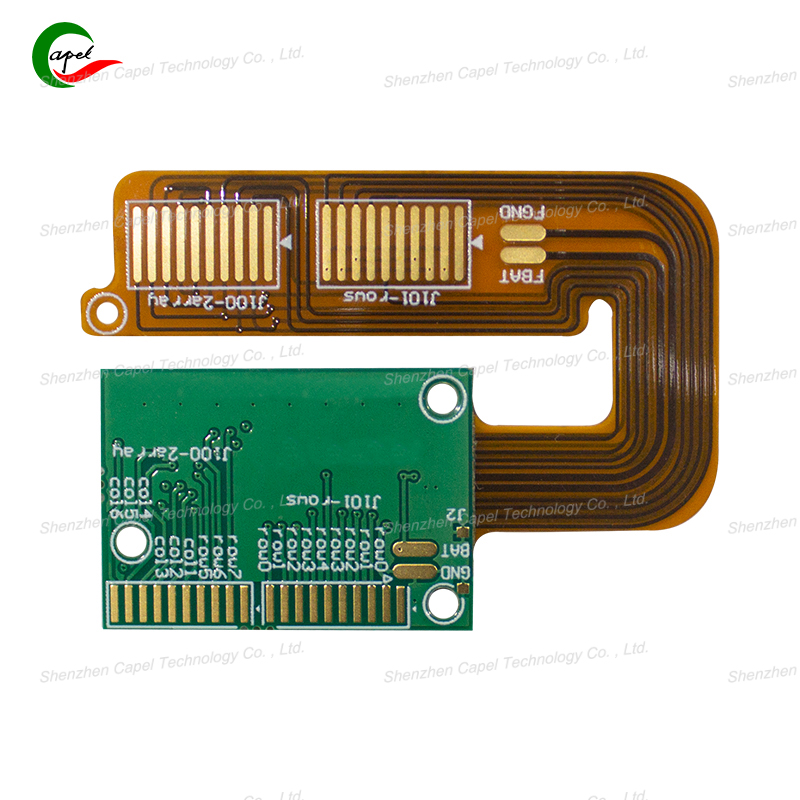

That experience taught us: rigid-flex PCB cost doesn’t have to be a barrier. The key is to optimize for what you need, not what’s “standard.” The changes we made saved us 35% on costs—and they’ll help you get the best value for your rigid-flex project.

Rigid-flex PCBs are pricier than rigid PCBs, but most of the extra cost comes from avoidable design choices—not the technology itself. Here are the three biggest cost drivers we found:

Many teams use 4+ layers for rigid-flex PCBs, assuming they need the extra strength. But most small devices (sensors, wearables) only need 2 layers. Each extra layer adds 20–30% to the cost—because it requires more materials, more lamination steps, and more labor.

“In our first design, we used 4 layers ‘just in case,’” Mia said. “Carlos pointed out we only needed 2 layers: one for signals, one for ground. Cutting to 2 layers alone saved us $2 per PCB.”

It’s easy to default to “industrial-grade” materials (like high-temperature PI film or gold plating) even if your device doesn’t need them. These materials cost 50–100% more than standard options—and they’re often unnecessary for consumer or low-stress industrial devices.

“We initially specified gold-plated traces for ‘durability,’” said our electrical engineer, Raj. “But our sensor only needs to last 3 years, and it’s not exposed to harsh chemicals. Switching to tin plating cut material costs by 30%.”

Rigid-flex PCB manufacturers have high setup costs (for lamination presses and laser cutters). If you order fewer than 100 units, you’ll pay a premium to cover those setup costs. Ordering 500+ units often triggers volume discounts—sometimes 15–20% off.

“Our first order was 200 units,” Mia said. “Carlos told us increasing it to 500 would get us a volume discount. Even though we didn’t need 500 right away, the cost per unit dropped from $10 to $8.50—and we could store the extra PCBs for future production.”

Optimizing cost isn’t about “cheapening out”—it’s about matching the design to your device’s needs. Here are the changes that helped us cut costs by 35%:

The number of layers is the single biggest cost driver for rigid-flex PCBs. Start with the minimum layers required for your design, and only add more if you must.

- We went from 4 layers to 2 layers. We rearranged the signal and ground traces to fit on 2 layers—no loss in performance, but a big cost cut.

- We avoided “blind/buried vias” (holes that only go through some layers). These require extra drilling steps and add $0.50–$1 per PCB. We used standard through-hole vias instead.

Layer-related costs dropped by 25%. “We tested the 2-layer PCB in the sensor— it worked just as well as the 4-layer version,” Raj said.

Ask your engineer: Can we rearrange traces to fit on fewer layers? Most of the time, the answer is yes—especially for simple devices.

Use standard materials unless your device has strict requirements (e.g., high heat, chemical exposure). Here’s how to balance quality and cost:

- PI Film: We switched from high-temperature Kapton VT (for -60°C to 200°C) to standard Kapton HN (for -20°C to 150°C). Our sensor operates at 0–60°C, so HN works perfectly—and it’s 25% cheaper.

- Plating: We changed from gold (for corrosion resistance) to tin (standard for low-stress use). Tin is cheaper and works for our 3-year lifespan.

- Adhesive: We used standard epoxy adhesive instead of “high-flex” adhesive. Our sensor only bends occasionally, so standard adhesive is strong enough.

Material costs dropped by 30%. “We tested the standard materials in our lab—they met all our performance requirements,” Raj said.

Make a “requirements list” for materials. For example: Operating temp: 0–60°C, lifespan: 3 years, no chemical exposure. Use this list to reject unnecessary premium options.

If you can, order more units to get volume discounts. Even if you don’t need all the PCBs immediately, storing them is cheaper than paying a premium for small orders.

- We increased our order from 200 to 500 units. The manufacturer gave us a 15% volume discount—cutting the cost per unit from $10 to $8.50.

- We negotiated “blanket orders”: We committed to buying 1,000 units over 6 months, and the manufacturer locked in the $7.80 per unit price for all orders. This protected us from future price hikes.

Volume discounts saved us $2.20 per unit. “Storing 300 extra PCBs was easy—they take up very little space,” Mia said.

Ask your manufacturer about “moq flexibility” (minimum order quantity). Many will lower the MOQ or offer discounts if you commit to future orders.

Complex flexible sections (e.g., sharp bends, irregular cuts) require custom laser cutting and extra testing—adding 15–20% to the cost. Simplifying the shape of the flexible section cuts labor and setup costs.

- We changed the flexible section from an irregular “U-shape” to a simple rectangular strip. The U-shape required custom laser programming; the rectangle used a standard template.

- We increased the bend radius from 0.5mm to 1mm. Sharp bends (≤0.5mm) need extra reinforcement (like FR4 stiffeners) to avoid cracking. A 1mm radius eliminated the need for stiffeners—saving $0.30 per PCB.

Flexible section costs dropped by 18%. “The rectangular strip fits the sensor just as well as the U-shape,” Raj said.

Use “standard bend radii” (1mm or larger) and simple shapes (rectangles, straight lines) for flexible sections. Your manufacturer likely has templates for these—saving time and money.

One of the biggest benefits of rigid-flex PCBs is that they replace multiple rigid PCBs connected by wires. But many teams still use extra components (like connectors) that add assembly cost. Instead, design the rigid-flex PCB to integrate functions—reducing the number of parts you need to assemble.

- We integrated the sensor connector directly into the rigid section of the PCB. Previously, we planned to use a separate connector (costing $0.70 per unit) and solder it to the PCB. Integrating it eliminated the extra part and assembly step.

- We added mounting holes to the rigid section. This meant we didn’t need a separate bracket to attach the PCB to the sensor case—saving $0.50 per unit on brackets.

Assembly costs dropped by 22%. “We used to need 3 extra parts—now we need zero,” Mia said. “The PCB fits the case and connects the sensor in one piece.”

Ask: Can the rigid-flex PCB replace any extra parts (connectors, brackets)? Integrating these functions cuts both part costs and assembly time.

After making these 5 changes, we not only hit our cost target but also improved the sensor’s performance:

The sensor launched last month, and it’s selling well—thanks to its compact size. “Customers love that it fits in their pocket,” Mia said. “If we’d stuck with the rigid PCB, we would have missed that key feature. Optimizing the rigid-flex cost let us have both: a small design and a tight budget.”

Our budget scare taught us that rigid-flex PCBs don’t have to be expensive—you just need to avoid overdesigning. Every cost driver we fixed (extra layers, premium materials, small orders) was a choice we made—not a requirement. By focusing on what our sensor needed (2 layers, standard materials, simple flexible shape), we cut costs without sacrificing performance.

For your next rigid-flex project, start with this question: What does my device actually need to work? Then build the design around those needs—not around “standard” or “safe” choices. The savings might surprise you—and you’ll get a PCB that’s perfectly tailored to your device, not just a one-size-fits-all expensive option.

Rigid-flex PCBs are about balance: saving space, improving reliability, and keeping costs in check. With the right optimizations, you can have all three—and that’s the real value of rigid-flex technology.