Date: 2026-01-27

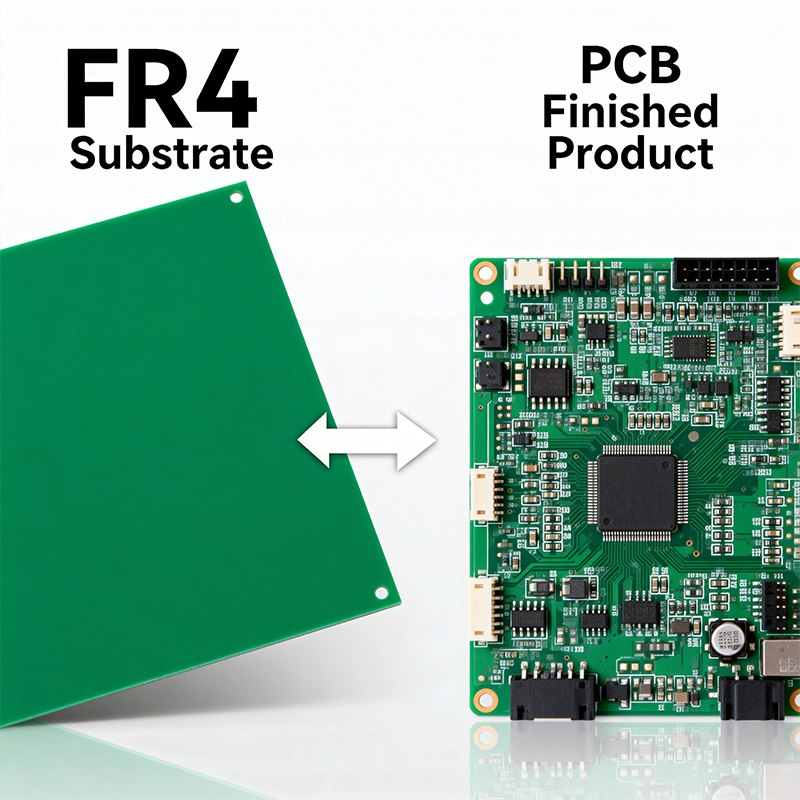

If you’ve ever worked with printed circuit boards (PCBs), you’ve definitely handled FR4. It’s by far the most common base material used in electronics. But what exactly is FR4, and why is it the go-to choice for so many manufacturers? Let’s break down its key properties in plain language.

First, What Does “FR4” Even Mean?

The name itself gives a couple of clues. “FR” stands for Flame Retardant, and the “4” indicates a specific woven glass fiber fabric combined with an epoxy resin binder. In simple terms, it’s a strong, fire-resistant composite material made of fiberglass cloth soaked in epoxy glue and then cured solid. Think of it as the “plywood” of the electronics world – a versatile, reliable, and affordable workhorse.

Key Properties That Matter for Electronics Manufacturing

Electrical Insulation (The Main Job)

This is the most critical property. FR4 is an excellent insulator, meaning it prevents electrical current from leaking between the copper traces on different layers. Its Dielectric Constant (Dk) and Dissipation Factor (Df) are stable enough for a vast range of applications, from simple power supplies to complex digital circuits.

Mechanical Strength & Rigidity

The woven fiberglass provides a robust, rigid structure – like the skeleton of the board. This gives the PCB the strength to withstand assembly processes, support heavy components, and resist warping during soldering (high temperatures). Its glass transition temperature (Tg) – the point where it starts to soften – is a key spec; standard FR4 has a Tg around 135°C, but higher grades (like FR4-Tg170) are available for lead-free soldering and tougher environments.

Flame Retardancy (Safety First)

The “FR” is not just a label. The material is formulated to self-extinguish, a crucial safety requirement for most commercial and consumer electronics to meet standards like UL94V-0. This means it won’t keep burning if exposed to a flame.

Thermal Performance

FR4 has decent, though not exceptional, thermal properties. It can handle the heat of standard soldering processes. However, for designs with very high power density, its relatively low thermal conductivity means heat might not spread away from hot spots quickly, which designers need to account for.

Moisture Resistance

It absorbs very little moisture from the air, which is vital. High moisture absorption could lead to issues like “popcorning” (delamination or cracks during soldering) or degraded electrical performance in humid conditions.

Machinability & Cost

It’s easy to drill, route, and process in PCB factories, which keeps manufacturing costs down. This excellent balance of performance and affordability is the core reason for its dominance.

Typical Applications (Where You’ll Find It)

Consumer electronics (routers, TVs, appliances)

Industrial control boards

Automotive electronics (non-critical modules)

Computer motherboards and expansion cards

LED lighting boards

When Might You Look Beyond Standard FR4?

FR4 is fantastic, but it has limits. You might consider other materials if your design requires:

Extremely High Frequencies (RF/Microwave): Materials with lower and more stable Dk/Df (like Rogers or PTFE-based substrates) are better for minimizing signal loss.

Very High Temperatures: Polyimide or ceramic-based substrates offer higher continuous operating temperatures.

Flexible Circuits: Obviously, you’d need a flexible material like polyimide (Kapton).

Maximum Thermal Management: Metal-core (IMS) or exotic ceramic substrates conduct heat far better.

In a nutshell, FR4 is the reliable, all-rounder material that makes the majority of electronics possible. Understanding its properties helps you design with its strengths in mind and know when it’s time to specify something more specialized.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..