Date: 2025-11-05

Let me walk you through how we turn a simple circuit board into something that can actually think and respond. It's like watching a skeleton grow organs and come to life.

Starting Point: The Bare Board - All Dressed Up with Nowhere to Go

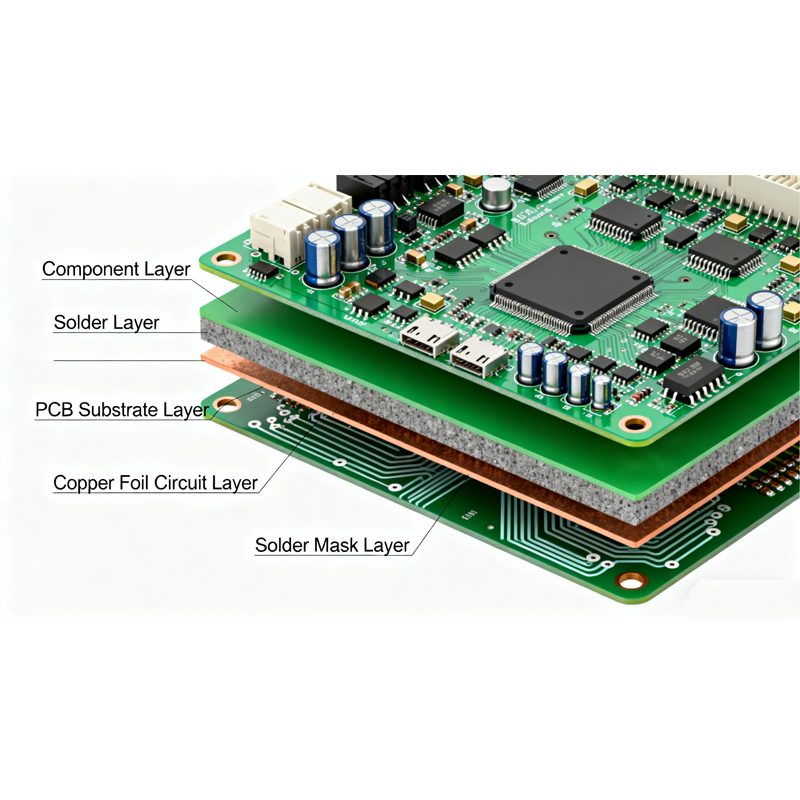

When we first make a PCB, it's just an empty platform. Think of it like a new house with all the wiring installed but no appliances or light switches. The board has:

The base material (usually that green fiberglass stuff)

Copper traces (like roads for electricity)

Holes and pads where components will go

But here's the thing - if you plug in this bare board, nothing happens. It's like having a car with no engine - looks nice but won't get you anywhere.

Step 1: Quality Check - Making Sure All the Parts Are Good

Before we start building, we check everything. You wouldn't want a doctor with broken hands doing your surgery, right? Same idea here.

We examine:

The bare boards for scratches or bad copper traces

All components - resistors, chips, sensors - to make sure they're the right type and not damaged

Why? Because one bad part can ruin the whole board

Step 2: Assembly - Putting All the Pieces in Place

This is where the magic starts. We take that empty board and start adding components.

First, we get everything organized:

We load components into tapes for our machines to use

We program our equipment with your board design

Then comes the assembly:

Our pick-and-place machines (think of them as super-precise robots) put tiny components like resistors and chips in exactly the right spots

For larger parts with wires, we either use special machines or have technicians insert them by hand

Now the board has all its parts, but they're not connected yet. It's like having all the car parts laid out but not bolted together.

Step 3: Soldering - Making Everything Stick Together

This is where we make permanent connections. We have two main methods:

For the small surface-mounted parts:

We run the boards through ovens that melt special solder paste

This creates strong electrical connections between components and the board

For the larger parts with wires:

We use wave soldering where boards pass over molten solder

The solder wicks up through the holes to make solid connections

Now electricity can flow between all the components. The board has gone from looking smart to actually being able to move electricity around.

Step 4: Testing - Making Sure Everything Works

Just because it looks good doesn't mean it works right. We put every board through rigorous testing:

Visual inspection:

We check for bad solder joints, missing parts, or components in wrong places

For chips with hidden connections, we use X-rays to see underneath

Functional testing:

We power up the board and see if it does what it's supposed to do

We might simulate real-world conditions - like testing a temperature sensor by actually changing the temperature around it

Repairs:

If we find problems, we fix them - replacing bad components, redoing solder joints

We don't ship anything that doesn't work perfectly

Step 5: The Final Touch - Making It Smart

This is the cool part - we program the brain of the board. For boards with microcontrollers, we load the software that tells them what to do.

For example, we might program a board to:

Read temperature from a sensor

Decide if it's too hot or too cold

Turn on a fan or heater accordingly

Then we clean off any manufacturing residue, package everything carefully, and ship it out.

The Big Picture

What started as a simple board with copper lines becomes something that can:

Sense its environment (through sensors)

Make decisions (through programmed chips)

Control other devices (through relays and outputs)

That empty board has become the smart heart of whatever device it's going into - whether that's a medical monitor, a smart home device, or industrial equipment.

The transformation isn't just about adding parts - it's about creating something that can interact with the world. And that's why what we do is equal parts science and magic.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..