Date: 2025-11-05

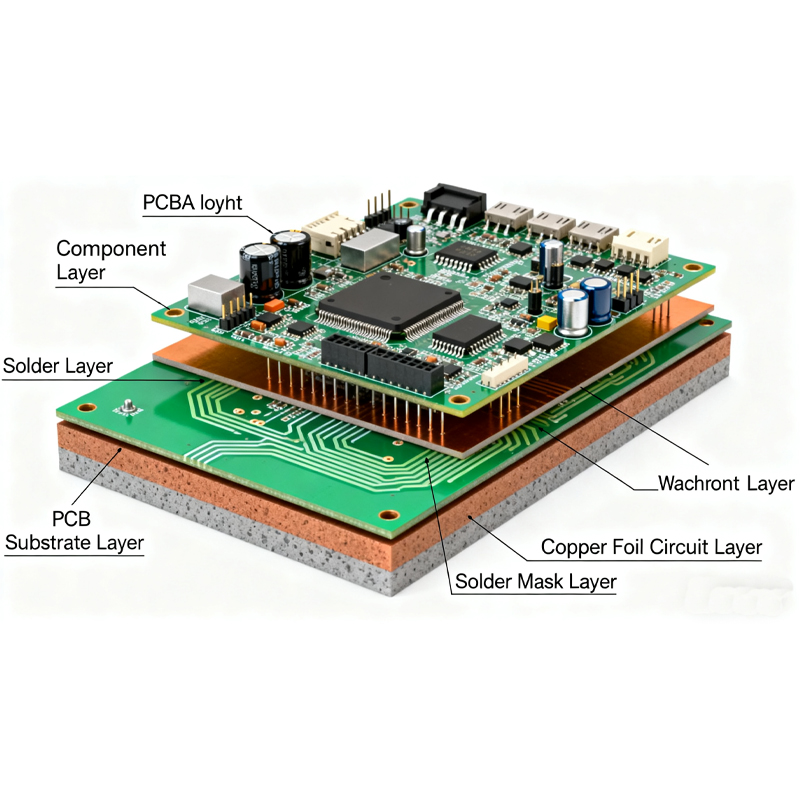

Let me break down why there's such a huge price gap between bare circuit boards and fully assembled ones. I've been in this business long enough to see customers' eyes pop when they get quotes for both.

The Parts Make All the Difference

Think of it like building a car:

A PCB is just the frame and body

A PCBA is the complete car with engine, seats, and everything

The bare board itself is cheap - we're talking basic materials like fiberglass and copper. Even fancy boards with multiple layers don't break the bank compared to what comes next.

The real cost comes from all those tiny components we stick on the board. A simple resistor costs almost nothing (we're talking fractions of a cent), but when you need hundreds per board, it adds up. Then there are chips - some of those little black squares can cost more than the rest of the components combined. I've seen single chips that cost more than my first car.

The Manufacturing Process Gets Complicated

Making bare boards is pretty straightforward - we etch copper, drill holes, and add protective coating. It's like printing on really expensive paper.

But assembling components? That's where things get pricey. We need million-dollar machines that place components with laser precision. We need special ovens that melt solder just right. And we need skilled technicians to handle the tricky stuff.

For small batches, the setup costs can be brutal. Programming the machines, loading components, quality checks - these take time whether we're making ten boards or ten thousand.

Testing: Where We Separate the Working from the Scrap

With bare boards, we basically just check if the copper lines connect properly. It's quick and cheap.

With assembled boards? We need to make sure every single component works and is properly connected. We use X-rays to look under chips, run power through the boards, and simulate real-world conditions. This equipment isn't cheap, and the testing takes time - which means money.

The Supply Chain Headache

Here's something most people don't think about: when you order bare boards, we're dealing with pretty stable materials. Copper and fiberglass prices don't jump around too much.

But with components? It's a rollercoaster. One month a chip costs $2, the next month it's $20 because of some factory fire in another country. We've had to tell customers their boards now cost twice as much because some tiny component became impossible to find.

Volume Changes Everything

If you want a thousand bare boards, the price per board drops like a rock. The machines love running the same thing over and over.

But with assembled boards, even big orders have limits. You might need 200 different components, and each has its own minimum order quantity. Changing from one board design to another means stopping the line and resetting everything - that downtime costs money.

Real Examples From Our Shop

Last week we quoted two customers:

Customer A wanted 10 bare boards: $12 each

Customer B wanted the same boards but assembled: $145 each

Why the huge difference? Customer B's boards needed a special processor that alone cost $85. Plus setup fees, testing, and all those little resistors and capacitors that add up.

Another customer ordered 500 assembled boards last month. Their cost per board was about $35, while the bare boards would have been about $4 each. The gap shrinks with volume, but never disappears.

The Bottom Line

When you're paying for an assembled board, you're not just paying for the materials. You're paying for:

All those components (especially any chips)

Expensive equipment and skilled labor

Thorough testing to ensure it works

The risk of component shortages and price jumps

The complexity of managing hundreds of different parts

A bare board is like buying flour and eggs. An assembled board is like buying a wedding cake - the ingredients are just the start of the cost.

That's why that little "A" in PCBA makes such a big difference in price. You're moving from a simple manufacturing process to a complex assembly operation that has to work perfectly every time.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..