Date: 2026-02-07

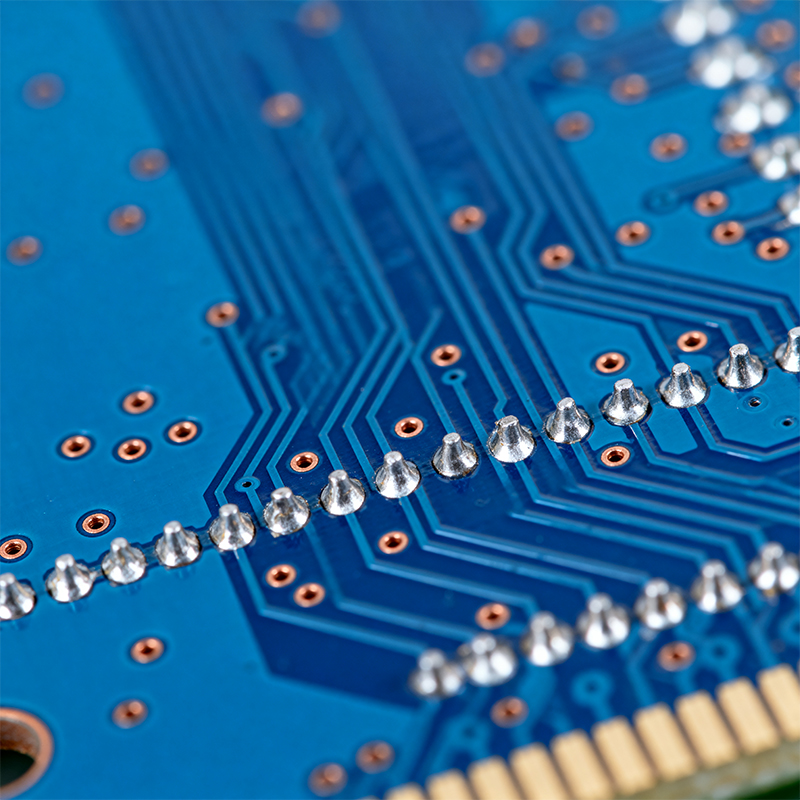

On a high-end server motherboard, the heads of over two hundred screws sit perfectly flush with the golden PCB surface—this flawless finish is made possible by the precise control of counterboring technology at the junction of mechanics and electronics.

When examining a sophisticated circuit board, you might notice that some screw holes are different. They aren’t just simple through-holes but feature a stepped, larger opening, allowing the screw head to sit entirely below the board's surface. This engineered feature is called a counterbore.

Far more than an aesthetic trick, the counterbore is a critical junction point in electronic device manufacturing. It seamlessly connects mechanical structures to circuit functionality, enabling slimmer designs, modular assembly, and reliable integration. In PCB designs that involve metal frames or heatsink mounting, over 70% utilize this essential technique.

Imagine a standard through-hole as a straight pipe. A counterbore is like that pipe with an enlarged “garage” at its entrance. This recess has a larger diameter and precise depth, designed specifically to house a screw head or nut, keeping its top surface level with the PCB.

The core purpose is to resolve spatial conflicts and enable flush mounting. A protruding screw head can prevent PCBs from stacking closely (as in backplane systems), cause interference inside an enclosure, or simply look unprofessional. The counterbore elegantly solves these issues.

A standard counterbore consists of two parts:

The Pilot Hole: The smaller, lower section where the screw shank passes through.

The Counterbore Recess: The enlarged upper section that houses the screw head. Its dimensions are dictated by standard screw head specifications (e.g., ISO, ANSI).

Counterbores are primarily defined by their location:

Standard Counterbore: Machined on the top or bottom layer of the PCB for a screw driven from that side.

Back Counterbore (or Spotface): Created on the bottom layer to accommodate a nut or bolt end inserted from the top, used for single-sided access or space constraints.

Design is governed by strict standards to ensure compatibility with common screw types like 82° Flat Head or 90° Countersunk screws, in both metric (e.g., M3) and imperial (e.g., #4-40) sizes.

A critical design rule: The depth of the counterbore must never break into the pilot hole. A full thickness of board material must remain between them to preserve structural integrity and clamping force.

Creating precise counterbores requires specialized processes:

CNC Milling: Offers the highest precision and flexibility, using a programmed micro end mill to create custom recesses. Ideal for prototypes and complex designs.

Specialized Drill/Counterbore Tools: A more cost-effective method for volume production, using a stepped tool to form the hole and recess in one operation.

The main challenges are chip evacuation and burr control. Effective methods like high-pressure air blast and post-machining deburring are essential to ensure clean, smooth holes.

Why use them? The benefits are tangible:

Maximizes Space: Enables ultra-tight PCB stacking, crucial for high-density systems like servers.

Enhances Safety & Aesthetics: Eliminates sharp protrusions that can damage components or wiring.

Improves Airflow: A flat surface reduces turbulence in cooled enclosures, aiding thermal management.

Facilitates Automation: Provides a smooth surface for automated assembly and testing equipment.

What are the costs? Important considerations include:

Increased Expense: Adds a machining step, raising PCB manufacturing cost and time.

Potential Weak Point: Locally reduces the board's cross-sectional area, which must be evaluated in high-stress applications.

Design Complexity: Requires precise definition in design files, increasing effort and potential for error.

Board Thickness Limits: May not be feasible on very thin PCBs (e.g., < 0.8mm).

This technology is vital in fields with extreme demands:

High-Density Computing: Blade servers and network switches rely on them for secure, compact PCB stacking.

Consumer & Industrial Electronics: Used in laptops and industrial controllers to secure PCBs within tight enclosures.

Thermal & EMI Management: Essential for securing large heatsinks and shielding cans flush to the board.

High-Reliability Sectors: In aerospace and automotive electronics, they help prevent vibration-induced loosening.

As devices get thinner, counterbore technology evolves:

Smarter Design Integration: Tighter links between PCB and mechanical CAD tools could allow automatic generation of machining data from 3D models.

Advanced Alternatives: Technologies like blind press-in nuts may offer stronger, cleaner connections for some applications.

Extreme Precision: The push for miniaturization will drive machining tolerances from hundredths of a millimeter toward the micron scale.

The counterbore, a small but critical feature, perfectly bridges the abstract world of circuit design and the physical world of mechanical assembly. It embodies an essential engineering principle: ultimate reliability is built on the precise execution of every detail. Mastering such fundamental techniques allows manufacturers to build more robust, compact, and professional electronic devices.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..