How to Choose a Reliable FPC/PCB Supplier: 5 Key Factors to Focus On

Date: 2025-08-17

For engineers and manufacturers, a reliable FPC/PCB supplier isn’t just a vendor—they’re a partner that can make or break your project. A bad supplier might deliver boards with hidden defects (like thin traces or weak adhesion) that cause costly delays or product failures. A good one, though, provides consistent quality, on-time delivery, and support when issues arise. To avoid costly mistakes, here are the 5 critical factors to evaluate when picking an FPC/PCB supplier.

Quality isn’t optional for FPC/PCBs—especially in industries like medical, automotive, or aerospace. A reliable supplier must have third-party certifications that prove their processes meet global standards.

- Look for ISO 9001 (quality management) and IATF 16949 (automotive-specific quality)—these ensure the supplier follows strict quality control (QC) steps, from material sourcing to final testing.

- For medical devices, check for ISO 13485 (medical device quality) and compliance with regulations like the EU’s MDR or the U.S. FDA’s QSR—this means their boards are safe for use in patient-facing products.

- Ask for test reports: A trustworthy supplier will share data on trace thickness, adhesion strength, or impedance (for high-frequency PCBs) instead of just saying “our quality is good.” For example, if you need FPCs for a foldable phone, ask for bend test results (e.g., “10,000 folds at 180° with no trace cracks”).

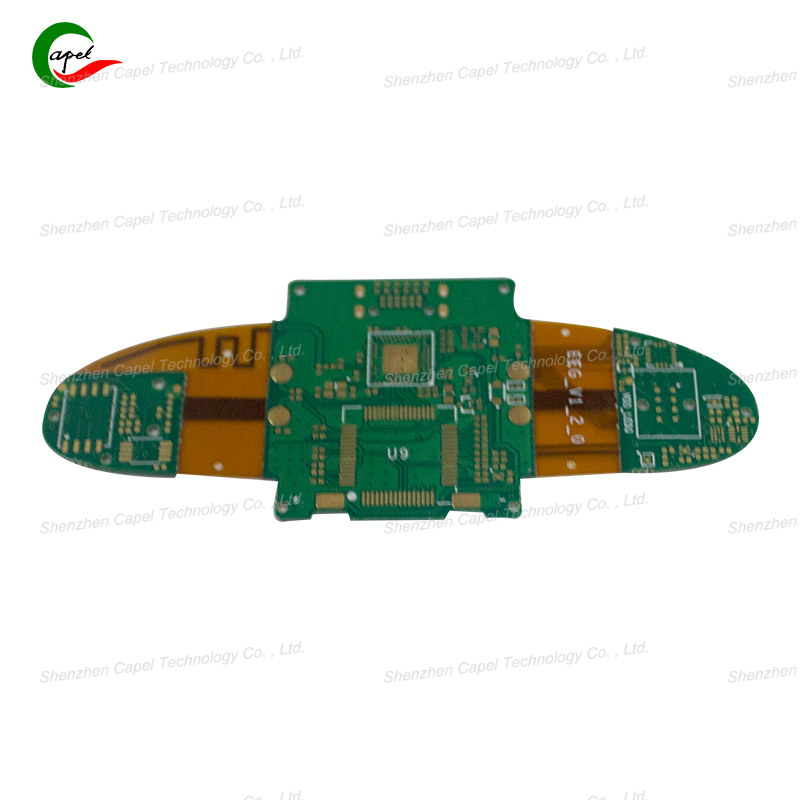

Not all suppliers can handle every FPC/PCB requirement. A supplier that makes basic rigid PCBs might struggle with complex rigid-flex designs or high-density FPCs.

- Clarify their technical limits: Ask, “What’s the minimum trace width you can etch?” (for FPCs, look for 0.075mm or smaller) or “How many layers can you do for rigid-flex PCBs?” (reliable suppliers handle 8–12 layers).

- Check for specialized equipment: For FPCs, they need automated lamination machines (to avoid bubble defects) and laser drills (for tiny vias). For high-frequency PCBs, look for impedance testing tools (like network analyzers) to ensure signal stability.

- Avoid “one-size-fits-all” suppliers: If you need FPCs for a wearable device (thin, flexible) and PCBs for an industrial sensor (heavy-duty), make sure the supplier has experience with both—don’t trust a supplier that only specializes in one type.

Delayed FPC/PCBs can stop your production line, leading to missed deadlines and lost revenue. A reliable supplier must have a stable supply chain and a track record of meeting delivery dates.

- Ask for their on-time delivery (OTD) rate: Aim for 95% or higher. A supplier with a 80% OTD rate will likely cause headaches.

- Check material sourcing: Do they have pre-approved material lists (PAML) with in-stock options (like standard PI films or FR-4)? Or do they rely on hard-to-source custom materials that cause delays?

- Plan for contingencies: Ask, “What happens if a material is out of stock?” A good supplier will have backup vendors or alternative materials (with your approval) to keep production on track.

Even the best designs need tweaks—and a reliable supplier should help, not just take orders.

- Look for engineering support: Will they review your FPC/PCB design before production? For example, a good supplier might flag a flex zone with a too-tight radius (which would cause cracks) and suggest a fix—saving you from a costly redesign later.

- Check post-delivery support: If you receive a batch with defects (e.g., delaminated layers), how quickly do they respond? A reliable supplier will investigate within 24 hours, offer a replacement batch, and share a root-cause analysis (RCA) to prevent future issues.

- Avoid suppliers that “ghost” you: If they take days to answer questions or ignore your design concerns, they’ll be even harder to work with when problems arise.

Low prices might seem appealing, but hidden costs (like setup fees for small batches or extra charges for testing) can quickly add up. A reliable supplier is transparent about pricing.

- Ask for a detailed quote: It should break down costs for materials, manufacturing, testing, and shipping—no vague “lump sum” numbers. For example, if they charge $500 for a setup fee, ask if it’s waived for repeat orders.

- Compare “total cost, not just unit cost”: A supplier with slightly higher unit prices but no hidden fees and faster delivery might be cheaper overall than a “low-cost” supplier that adds surcharges or causes delays.

Beware of unrealistic discounts: If a supplier’s price is 30% lower than competitors, they’re likely cutting corners on quality (e.g., using cheap adhesive for FPCs) which will cost you more in the long run.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.