For manufacturers building complex devices—from medical wearables to automotive sensors—choosing between rigid-flex PCBs and traditional rigid PCBs isn’t just a technical decision; it’s a financial one. Traditional PCBs are cheaper upfront, but rigid-flex boards often deliver long-term savings by cutting assembly time, reducing component costs, and lowering failure rates. To help manufacturers weigh the tradeoffs, we break down the cost differences, hidden savings, and scenarios where each option makes the most financial sense.

Traditional PCBs: The biggest advantage here is lower initial cost. Standard rigid PCBs use widely available materials (FR-4, basic copper foil) and simple manufacturing processes (etching, single-layer lamination). For a low-complexity project—like a basic IoT sensor—a 10,000-unit order of traditional PCBs might cost $0.50–$1.00 per board.

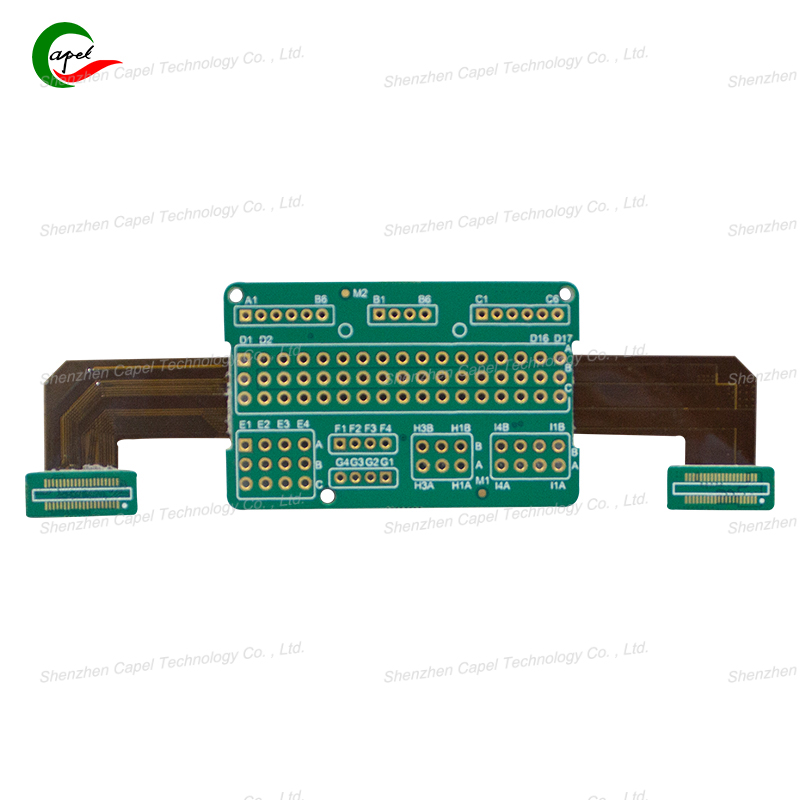

Rigid-Flex PCBs: Upfront costs are 20–50% higher. They require specialized materials (polyimide for flex zones, high-temp adhesives) and extra manufacturing steps (precision lamination of rigid/flex layers, transition zone testing). The same 10,000-unit order for rigid-flex could cost $0.70–$1.50 per board.

But here’s the catch: For small-batch orders (e.g., 500 units of a medical device), the gap narrows. Traditional PCBs often need custom tooling for connectors or wiring harnesses, adding $500–$1,000 in setup fees. Rigid-flex PCBs, which integrate flex and rigid sections in one piece, skip these extra tools—so the total upfront cost difference might drop to just 10–15%.

Traditional PCBs: Assembling devices with multiple rigid PCBs requires extra steps: soldering wires or connectors to link boards, adding brackets to hold them in place, and manually aligning components. For a device with 3 separate rigid PCBs (e.g., a smartwatch with a display board, sensor board, and battery board), assembly takes 2–3 minutes per unit—adding $0.30–$0.50 in labor costs per device.

Rigid-Flex PCBs: They eliminate most of these steps. A single rigid-flex board replaces 2–3 traditional PCBs and the wires/connectors between them. Assembly time drops to 30–60 seconds per unit, cutting labor costs by 50–70%. For that 10,000-unit smartwatch order, rigid-flex saves $3,000–$3,500 in assembly labor alone.

Real example: A consumer electronics manufacturer switched from 2 traditional PCBs to 1 rigid-flex board for their wireless earbuds. Assembly time fell from 1.5 minutes to 40 seconds per unit, and they eliminated $2,800 in connector costs for a 5,000-unit run.

Traditional PCBs: The more connectors and wires you add, the higher the failure rate. Wires can fray, connectors can loosen, and misaligned boards can short-circuit. For a car infotainment system using 4 traditional PCBs, the failure rate might be 3–5% within the first year—each failure costs $20–$50 to repair under warranty. For 10,000 units, that’s $6,000–$25,000 in warranty costs.

Rigid-Flex PCBs: Fewer moving parts mean fewer failures. The flex zones act as built-in “wires” that don’t fray, and the one-piece design eliminates connector-related issues. Failure rates for rigid-flex in the same infotainment system drop to 0.5–1%, cutting warranty costs to $1,000–$5,000 for 10,000 units.

Critical for high-stakes industries: In medical devices (e.g., glucose monitors), a traditional PCB failure could lead to recall costs—easily $100,000+. Rigid-flex’s lower failure rate makes it a financial safeguard here.

When you add up upfront, assembly, and failure costs, the TCO tells the real story:

- Simple devices (e.g., basic remote controls): Traditional PCBs are cheaper. TCO for 10,000 units: ~$8,000 (vs. $11,000 for rigid-flex).

- Moderately complex devices (e.g., smartwatches): Rigid-flex breaks even at ~5,000 units and saves money after that. TCO for 10,000 units: ~$12,000 (vs. $15,000 for traditional PCBs).

Highly complex devices (e.g., automotive ADAS modules): Rigid-flex is a no-brainer. TCO for 10,000 units: ~$20,000 (vs. $35,000 for traditional PCBs)—thanks to massive assembly and warranty savings.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.