In the realm of electronics manufacturing, Flexible Printed Circuits (FPC) play a pivotal role, serving as the connective lifeline in a myriad of devices from smartphones to medical equipment. Their flexibility, lightweight design, and space - saving capabilities make them indispensable. However, not all FPCs are created equal. As someone deeply involved in the industry, knowing how to distinguish high - quality FPCs from subpar ones is crucial. Here’s a comprehensive guide tailored to help you make informed judgments.

The first step in assessing an FPC’s quality is a thorough visual check, as many flaws can be spotted with the naked eye or a basic magnifying tool.

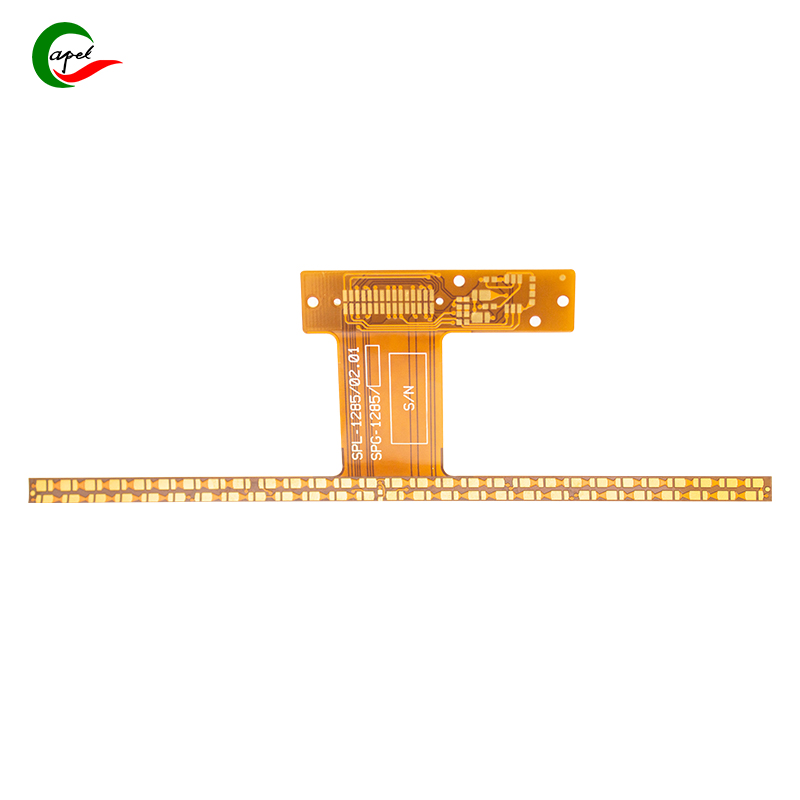

Take a close look at the copper traces. These are the conductive pathways that enable the flow of electricity. High - quality FPCs have copper traces that are uniform in width and thickness. There should be no signs of thinning, thickening, or irregular edges. If you notice any of these issues, it could indicate poor manufacturing processes, which may lead to electrical resistance problems or even short circuits down the line.

Next, examine the substrate material. The substrate is the base on which the copper traces are printed. It should have a smooth surface without any bubbles, wrinkles, or cracks. Bubbles can form when the adhesive between the copper and substrate is not applied properly, compromising the structural integrity and potentially causing delamination over time. Wrinkles and cracks, on the other hand, can weaken the FPC and make it more prone to damage during installation or use.

Don’t forget to check the solder mask. The solder mask is a protective layer that covers the copper traces, preventing solder from bridging between them. A good solder mask should be evenly applied, with sharp edges and no gaps. Uneven application or gaps can result in solder shorts, which are a common cause of device failure.

One of the key advantages of FPCs is their flexibility, so testing this property is essential. Gently bend the FPC in different directions, simulating the conditions it will encounter in real - world use. A high - quality FPC should bend smoothly without any cracking or peeling of the layers.

To test durability, you can perform a repeated bending test. Bend the FPC back and forth a certain number of times (depending on the application requirements) and then check for any signs of damage, such as broken copper traces or delamination. A quality FPC should withstand a reasonable number of bending cycles without failing.

The electrical performance of an FPC is critical to its functionality. You can use a multimeter to check for continuity between different points on the circuit. This ensures that the copper traces are not broken and that the connections are intact.

Another important aspect is insulation resistance. Using an insulation resistance tester, measure the resistance between the copper traces and the substrate or between different copper traces that should be insulated. A high insulation resistance indicates good insulation, reducing the risk of electrical leakage.

For high - frequency applications, it’s necessary to check the impedance of the FPC. Impedance mismatch can cause signal loss and distortion. Specialized impedance testing equipment can be used to verify that the FPC meets the required impedance specifications.

The manufacturing processes have a significant impact on the quality of an FPC. Look for signs of precise manufacturing, such as clean cuts on the edges of the FPC and accurate alignment of the layers.

The quality of the adhesive used to bond the layers together is also important. Poor - quality adhesive can lead to delamination, especially under harsh environmental conditions (such as high temperature and humidity).

In addition, check for the presence of any contaminants, such as dust or particles, on the surface of the FPC or between the layers. Contaminants can cause short circuits or affect the adhesion of the layers.

Reputable manufacturers adhere to strict industry standards and obtain relevant certifications. Look for FPCs that comply with standards such as IPC (Association Connecting Electronics Industries) specifications. These standards cover various aspects of FPC manufacturing, including materials, design, and testing, ensuring a certain level of quality.

Certifications such as ISO 9001 (Quality Management System) and ISO 14001 (Environmental Management System) also indicate that the manufacturer has a robust quality management system in place and is committed to environmental responsibility.

In conclusion, identifying the quality of FPC flexible circuit boards requires a combination of visual inspection, testing of flexibility and durability, checking electrical performance, evaluating manufacturing processes, and considering certifications. By following these steps, you can make more informed decisions when selecting FPCs for your applications, ensuring the reliability and performance of your electronic devices.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.