Picture this: A batch of wireless earbuds ships to customers, only for 20% of them to stop working after two weeks. Or a medical monitor fails mid-operation because its internal PCB loses connection. These disasters aren’t just costly—they ruin brand trust. The root cause? Skipping or cutting corners on FPC (Flexible Printed Circuit) and PCB (Printed Circuit Board) reliability testing.

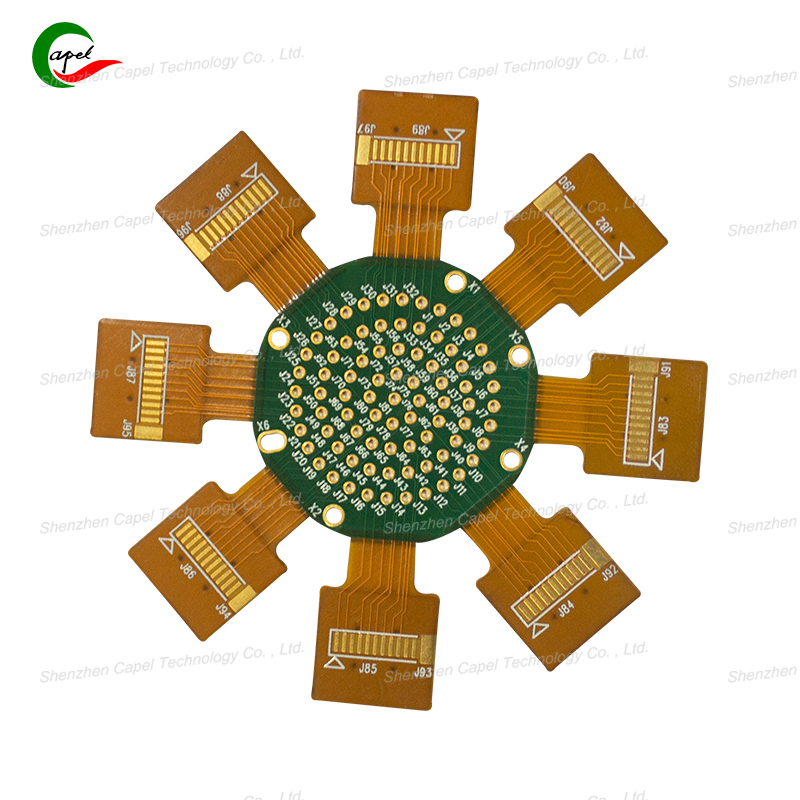

FPCs and PCBs are the "nervous systems" of electronics, but they’re fragile: FPCs bend thousands of times, while PCBs face heat, moisture, and vibration. Without rigorous testing, even a tiny flaw (like a cracked copper trace or loose solder) can turn into a big problem. Here are the 4 essential testing methods that every manufacturer must use to guarantee quality.

Before any other tests, you need to check if the FPC/PCB conducts electricity correctly. The most common method is Continuity Testing—using a multimeter or automated test equipment (ATE) to verify that current flows smoothly between all intended points. For example, a smartphone PCB has hundreds of connections; a single broken path can make the camera or charging port stop working.

Another key test is Insulation Resistance Testing. It measures how well the PCB’s non-conductive layers block unwanted current (e.g., between adjacent copper traces). A leading laptop brand once avoided a recall by catching low insulation resistance in 5% of its PCBs—this issue would have caused short circuits over time.

Electronics don’t live in perfect conditions—they get hot in pockets, wet in rain, and shaken in bags. That’s why environmental testing is critical:

-

Temperature Cycling Test: FPCs/PCBs are exposed to extreme temperatures (e.g., -40°C to 85°C) repeatedly. This mimics seasonal changes or device overheating. Apple tests its watch FPCs through 1,000 temperature cycles—if the circuits break, the watch won’t survive a cold winter day.

-

Moisture Resistance Test: Using a humidity chamber, samples are kept at 95% humidity and 60°C for weeks. Samsung uses this test for its foldable phone PCBs—any water damage would make the screen unresponsive.

-

Vibration Test: Devices are shaken at frequencies similar to car rides or backpacks. Tesla tests its EV PCBs this way—loose connections could cause critical system failures.

For FPCs (used in foldable phones, smartwatches), bend testing is non-negotiable. Machines fold FPCs back and forth—sometimes 200,000 times—to mimic real use. A Chinese tech firm once failed this test: its foldable phone FPCs cracked after 50,000 folds, leading to a product delay.

For PCBs (used in laptops, TVs), torsion testing checks if the board can handle slight twisting (e.g., when a laptop is opened roughly). Manufacturers also do solder joint strength testing—pulling on components to ensure they don’t fall off. Dell uses this for its laptop PCBs—weak solder joints would make the keyboard or trackpad fail.

Reliability testing isn’t a "nice-to-have"—it’s the only way to make sure FPCs/PCBs work when customers need them. A single untested batch can cost millions in recalls, lost sales, and damaged reputation. By using these 4 methods, manufacturers don’t just build better electronics—they build trust with every user. Whether it’s a smartwatch tracking a workout or a medical device saving a life, reliable FPCs/PCBs start with rigorous testing.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.