Date: 2026-01-08

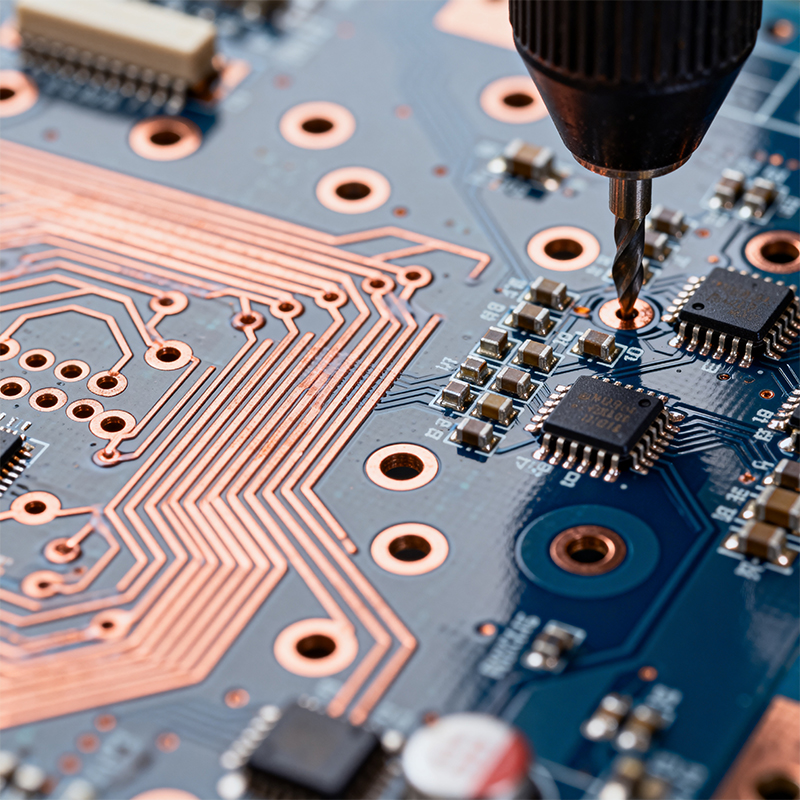

In electronics manufacturing, when the conversation shifts from consumer products to industrial applications—whether for controllers on automated production lines, monitoring devices in harsh environments, or communication systems requiring uninterrupted, long-term operation—the focus naturally converges on one core aspect: long-term reliability.

This means the circuit board must perform well not just in a climate-controlled lab, but also under real-world challenges like temperature swings, vibration, dust, or continuous operation, maintaining stability for years or even decades.

This reliability isn't accidental. It's engineered through a series of deliberate choices in design, materials, and manufacturing processes.

Starting with the Substrate

Industrial projects often prioritize materials with more stable performance. For example, using FR-4 with a high Glass Transition Temperature (High-Tg) ensures the board doesn't soften or deform under sustained heat. For applications demanding exceptional heat dissipation or extreme temperature resistance, specialized materials like metal-core substrates or polyimide may be chosen. The material is the first cornerstone of reliability.

Stricter Process Control & Documentation

While consumer electronics manufacturing balances efficiency and cost, industrial manufacturing prioritizes consistency. This is reflected in the precise control of every process parameter—from the thickness and shape of solder paste deposits to the settings and real-time monitoring of each zone in the reflow oven. Clear standards and complete documentation are in place. This traceability ensures process stability and allows any deviation to be promptly analyzed and corrected.

Testing and Validation Beyond the Basics

Functional testing is only the starting point. To simulate conditions over the product's entire lifecycle, industrial PCBs often undergo a suite of environmental stress tests. Examples include damp heat aging to screen for early failures, thermal cycling to verify the endurance of materials and solder joints through expansion and contraction, and vibration testing to ensure mechanical integrity. These tests aim not just to "pass," but to proactively identify and eliminate potential flaws.

End-to-End Traceability

From batch numbers of key components to production line logs and final test data, all information is systematically recorded and managed. If a rare issue emerges years later in the field, this complete traceability chain helps quickly pinpoint the root cause and implement precise corrective actions, which is vital for maintaining brand reputation and customer trust.

When a design needs to be transformed into an industrial-grade product, the depth of collaboration with the manufacturing partner often determines the outcome.

The Significant Value of Early Design Collaboration

A manufacturer with industrial project experience can provide valuable Design for Manufacturing (DFM) and Design for Reliability (DFR) feedback during the design phase. They might point out that certain component placements hinder heat dissipation or suggest stress relief designs for specific solder joints. At Kaboer in Shenzhen, our engineering team regularly participates in such early reviews, aiming to resolve potential long-term reliability issues before production begins.

Expertise in Supply Chain Management

Industrial projects have higher demands for component quality levels, lifecycle, and supply stability. Whether a manufacturer possesses the capability to manage such a specialized supply chain and ensure the long-term reliability of materials is a critical factor for project success.

Transparent Communication & Shared Standards

Smooth collaboration, starting from defining clear technical specifications and acceptance criteria, through transparent updates on production progress and shared test data, to joint problem-solving when issues arise, is essential for navigating complex industrial projects.

The essence of industrial PCB manufacturing lies in systematically, repeatably, and rigorously building reliability into every product. For Kaboer in Shenzhen, this means operating dedicated production and quality control processes for industrial and high-reliability products within our own factory. We understand that for clients in industrial fields, we are delivering not just a hardware component, but also the confidence for their end product's stable operation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..