Date: 2026-01-10

If you're looking into surface mount for your product, you're probably trying to solve a practical puzzle. Maybe it's about making your device smaller, fitting in more features, or figuring out how to manufacture it efficiently. It's a term that comes up whenever modern electronics are being built, and understanding its real-world impact is key.

Let's walk through what surface mount actually means on the factory floor and how it influences your design, costs, and timeline.

In simple terms, surface mount refers to the method of placing electronic components directly onto the surface of a circuit board. The components (called SMDs or Surface Mount Devices) sit flat and are soldered to pads on the board.

The alternative is the older through-hole method, where component leads go into drilled holes. Think of it like the difference between gluing a tile onto a floor (surface mount) versus plugging a peg into a hole (through-hole). This fundamental shift is why our devices have gotten so much smaller and more powerful.

Beyond just enabling miniaturization, surface mount brings concrete advantages that matter when you're managing a production schedule and budget:

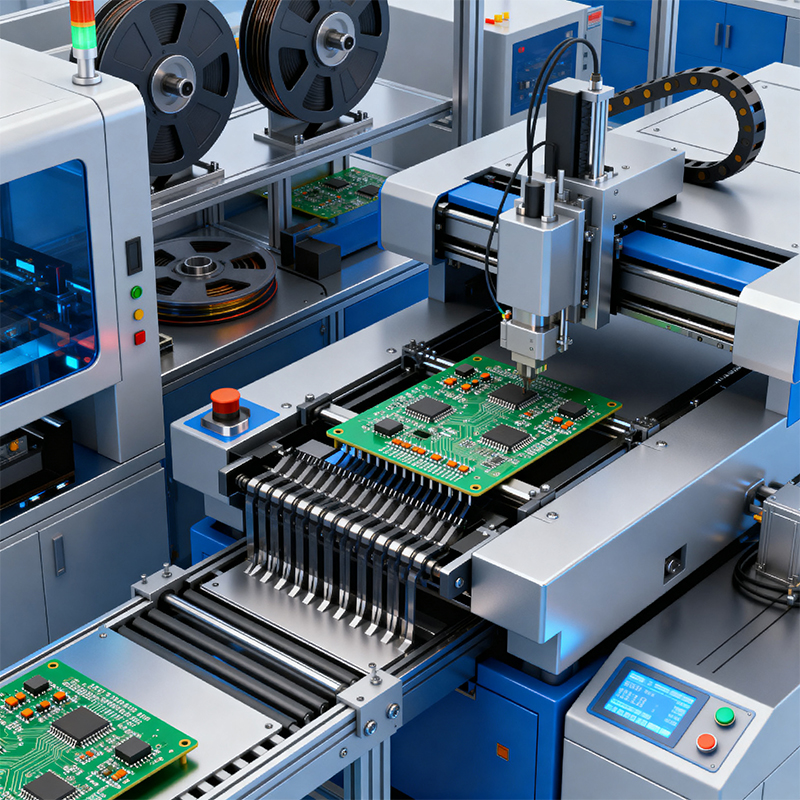

It's Built for Automation: Surface mount assembly lines are fast. Automated machines can place tens of thousands of tiny components per hour with extreme precision. This speed translates directly into the ability to scale up production without a proportional increase in time or assembly cost.

It Opens Up Component Options: The latest chips, sensors, and microcontrollers are almost exclusively designed as surface-mount packages. Using SMDs gives you access to better performance and newer technology.

It Can Lower Overall Costs: While the upfront setup requires precision tooling (like stencils), the high speed and reduced board material (fewer drilled holes) often lead to a lower cost per unit in volume production.

Adopting surface mount isn't just a switch you flip. A few practical points need attention to ensure a smooth process:

Design for Manufacturing (DFM) is Crucial: Your PCB layout needs to be designed with the assembly process in mind. Proper pad sizes, spacing between components, and thermal relief patterns are not optional—they're essential for a board that can be reliably built.

The Right Partner Makes All the Difference: Not all assembly houses are equal. Successful surface mount production depends on precise equipment (like pick-and-place machines and reflow ovens), strict process control, and thorough inspection (using AOI or X-ray).

Supply Chain Becomes More Critical: Using hundreds of tiny SMDs means managing a complex bill of materials. Ensuring a reliable supply of authentic components is a significant part of the battle.

This is where partnering with a dedicated surface mount expert streamlines the journey from design to delivery. They handle the intricacies so you don't have to.

A good partner manages the entire ecosystem:

Pre-Production Review: They analyze your design files to spot potential manufacturing issues before the board is ever made.

Component Sourcing & Management: They procure all the necessary SMDs, verifying quality and managing inventory.

Precision Assembly: They run the automated lines, control the soldering process, and perform rigorous inspections.

Testing & Final QC: They ensure the assembled boards function correctly before they ship.

At Kaboer, our factory in Shenzhen is built around surface mount excellence. We see ourselves as an extension of your production team, focusing on the reliability and efficiency of this core process.

For our clients, this translates to:

Fewer Headaches: We take on the burden of process optimization and supply chain management.

Higher Consistency: Our controlled environment and automated inspection aim for the same high quality on every board, from the first prototype to the thousandth unit.

A Clearer Path to Market: With the assembly complexities in expert hands, you can focus on product development and business growth.

For nearly all modern electronic products, the answer is yes. The real question is: do you have the expertise and infrastructure in-house to execute it flawlessly, or would partnering with a specialist free up your team and de-risk the process?

For teams that want to leverage the benefits of surface mount without getting bogged down in its operational details, finding a capable manufacturing partner is often the most strategic and efficient path forward.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..