Date: 2026-01-10

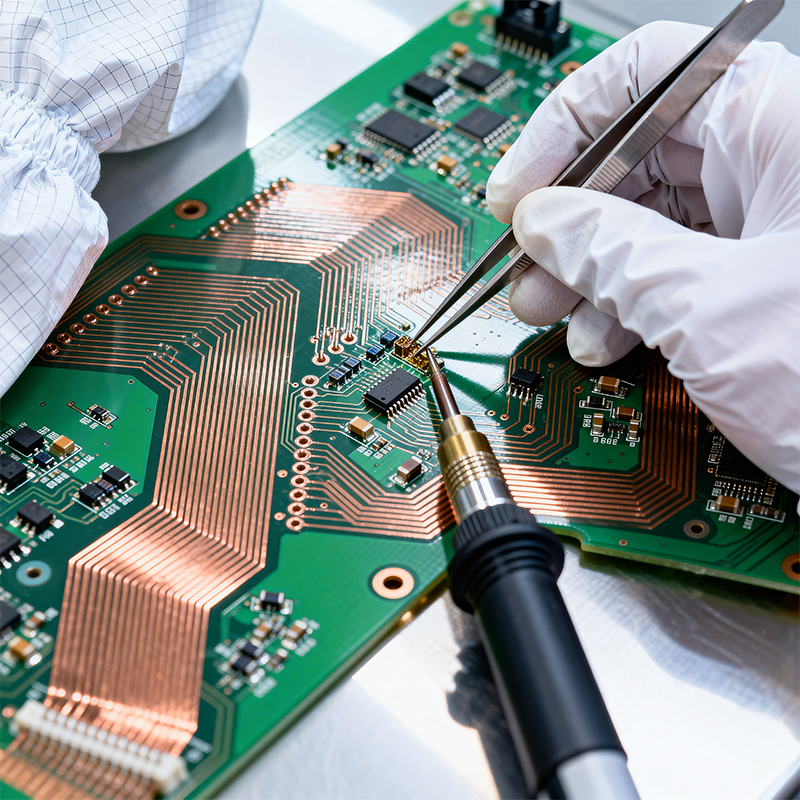

Ever feel like assembling circuit boards looks straightforward on paper, but gets tangled up in reality? You're not alone. Between sourcing tiny components that seem to disappear into thin air, managing a dozen different suppliers, and hoping the solder joints come out right, the process can test anyone's patience.

If you're looking at your next board build and wondering how to make it smoother, let's have a real conversation about what works and what doesn't.

There's a common idea that if you have the design files and the parts, assembling circuit boards is just a matter of time and a steady hand. For a one-off prototype, maybe. But when you need ten, a hundred, or a thousand units that all work exactly the same? That's when the game changes completely.

It becomes less about soldering skill and more about managing a process. A process that includes:

The waiting game: Aligning the delivery of your bare PCBs with the arrival of 50 different component reels from various corners of the globe.

The "oops" factor: A single mis-picked resistor value or a slightly off-center chip placement can scrap an entire batch.

The inspection black hole: How do you really know every one of the 500 boards you just got is perfect? Spot-checking a few isn't enough.

You might be managing assembly in-house or with a small shop. Things often start well, but pressure points appear as you grow:

Your Team Becomes a Logistics Department: Your engineers spend more time tracking packages, arguing with parts suppliers, and debugging assembly faults than they do on actual engineering.

Quality Becomes a Roll of the Dice: One batch is perfect, the next has mysterious failures. Without standardized processes and professional inspection gear, consistency is hard to lock down.

Hidden Costs Start Showing Up: It’s not just the cost of the parts and labor. It's the expedited shipping fees, the yield loss from errors, the inventory of leftover components, and the time cost of delayed product launches.

This is why so many smart companies treat assembling circuit boards as a strategic partnership, not just a task to outsource. They find a dedicated PCBA partner and let them handle the operational heavy lifting.

Think of it like this: you wouldn’t build your own semiconductors from scratch. You'd buy them from a chip fab. Professional board assembly is similar in spirit—it's about leveraging someone else's core infrastructure and expertise so you can focus on yours.

A true partner handles the entire ecosystem:

Procurement & Supply Chain: They have the networks to get real parts, at good prices, and manage shortages.

Process Control: They run calibrated machines (stencil printers, pick-and-place, reflow ovens) and have strict quality gates (AOI, X-ray, testing).

Accountability: One team, one point of contact, responsible for delivering a working, tested product to your door.

At Kaboer, with our own factory in Shenzhen, we’ve built our entire operation around taking the chaos out of assembling circuit boards. We become your on-the-ground production team.

For our clients, the value shows up in day-to-day relief:

We start with a reality check. Before we build anything, our engineers review your files. We'll flag things like parts that are notorious for being hard to source or design quirks that could cause assembly headaches. It’s our job to see these things coming.

We act as your supply chain buffer. Sourcing is what we do all day, every day. We know the reliable vendors, we spot the risky ones, and we manage the inventory so you don't have to.

We obsess over consistency. Our factory floor is set up for repeatability. From the temperature of our solder paste to the programming of our inspection cameras, we control the variables so you get predictable results.

You get a single, clear outcome. Instead of a pile of parts and a stack of bare boards, you receive fully assembled, tested PCBAs, ready for the next step in your production line.

Ask yourself a few honest questions:

Is my team spending too much time on board assembly logistics?

Am I confident in the consistent quality of every unit I ship?

Could my product get to market faster if this process was more streamlined?

If you answered "yes" to any of these, it might be time to explore what a professional assembly partnership looks like. It’s not about giving up control; it’s about gaining a more reliable and efficient kind of control through the right partner.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..