Last month, I sat down with Maria, a senior electronics engineer at a leading wearables company, as she tore apart a faulty smart bracelet in her lab. “Look at this,” she said, pointing to a thin, wavy circuit board snaking around the bracelet’s curved frame—an FPC, or Flexible Printed Circuit. “This little piece makes or breaks the user experience. If its power drain is too high, the bracelet dies by lunch. If it’s not flexible enough, it cracks when someone bends their wrist. And the rigid-flex PCB inside? The tiny holes connecting its layers? One off-center drill, and the whole thing is garbage.”

Maria’s frustration is relatable to anyone in wearable tech. Smart bracelets aren’t just fashion accessories—users demand 5+ days of battery life, durability for workouts, and a slim, comfortable fit. None of this is possible without two critical engineering feats: FPCs that balance low power use with flexible design, and rigid-flex PCBs with pinpoint-precise micro-holes. Let’s pull back the curtain on how these technologies work, with real stories from factories and labs.

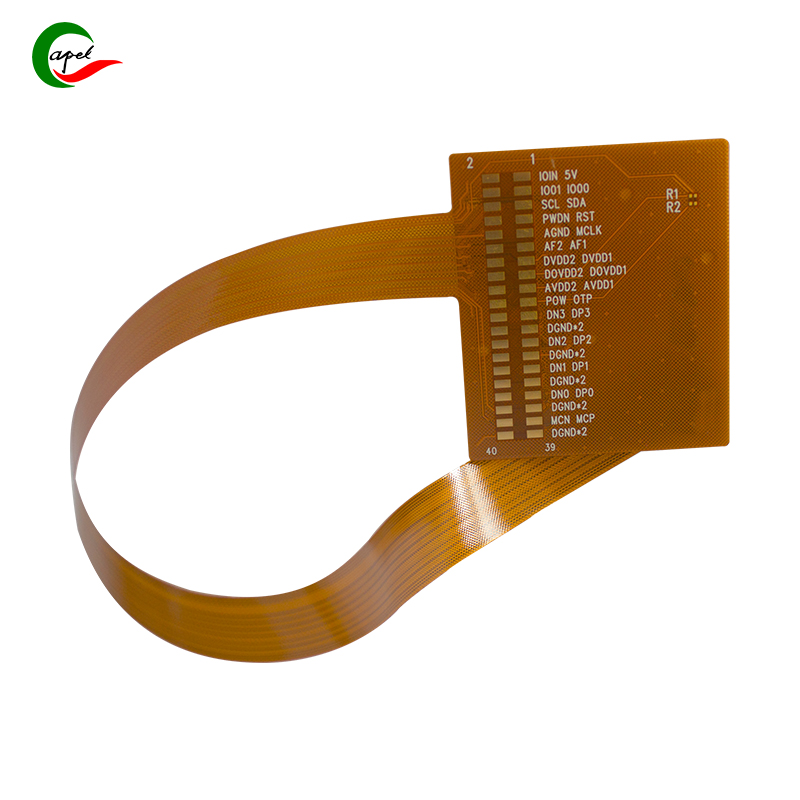

An FPC is the “backbone” of a smart bracelet. Unlike rigid PCBs, it bends with the device’s curved shape, fitting seamlessly under the wrist. But flexibility alone isn’t enough—if the FPC wastes power, users will abandon the product. The key is to design circuits that sip, not gulp, energy while leveraging the FPC’s flexible structure.

Maria’s team learned this lesson the hard way in 2022. They were developing a budget smart bracelet and used a standard voltage regulator (a component that stabilizes power) on the FPC. “We thought it was fine—until testing showed the battery died in 2 days instead of 5,” she recalled. The problem? The regulator drew 10 microamps of current even when idle—too much for a device that spends 90% of its time in “sleep mode.”

They swapped it for a low-quiescent-current (low-IQ) regulator that uses just 0.5 microamps when idle. But there was a catch: the new regulator was slightly larger, and the FPC’s tight bend radius (just 2mm) risked cracking the component’s solder joints. “We had to reposition it along the FPC’s ‘gentle curve’—the part that bends the least,” Maria said. “By matching the component’s size to the FPC’s flexibility, we cut idle power use by 95% and avoided cracks.”

This is the first rule of FPC power adaptation: choose components with ultra-low power needs and place them where the FPC bends the least. For example:

- Microcontrollers (MCUs): Use “ultra-low-power” models (like Texas Instruments’ MSP430) that draw <1 microamp in sleep mode.

- Sensors: Opt for motion sensors (e.g., Bosch’s BMA423) that auto-switch to low-power mode when not in use.

- Placement: Keep larger, rigid components (like regulators) on straight sections of the FPC; reserve curved areas for thin, flexible traces (the copper paths that carry electricity).

The traces on an FPC are like tiny roads for electricity—wider or longer roads waste more power (due to “resistance”). But making them too thin risks breaking when the FPC bends. Maria’s team solved this with a “golden middle” approach:

- Trace Width: They use 0.1mm-wide traces (thinner than a human hair) for low-current paths (like sensor signals), which cut resistance by 30% compared to 0.2mm traces. For higher-current paths (like battery connections), they use 0.3mm traces to avoid overheating.

- Trace Length: They “route” traces in the shortest path possible. For example, instead of a trace looping around the FPC’s edge (adding 5mm of length), they run it straight across a flexible section—saving 15% of power loss.

- Bend Zones: They avoid placing traces in the FPC’s “high-bend” areas (like the wrist’s inner curve). If a trace must be there, they coat it with a thin layer of polyimide (a flexible polymer) to prevent cracking.

In 2023, this design cut power loss in their FPCs by 22%—enough to add an extra day of battery life to their smart bracelet.

Smart bracelets don’t use all components at once. When you’re sleeping, the heart rate sensor works, but the touchscreen doesn’t. Maria’s team uses “power gating”—a circuit design that shuts off power to idle components—directly on the FPC.

They added tiny, flexible switches (called “MOSFETs”) to the FPC that disconnect power to the touchscreen, Bluetooth module, and LED display when not in use. For example:

- When the bracelet is in “sleep mode,” the Bluetooth module’s power is cut off, saving 80% of its usual 5mA current draw.

- When the user stops moving (e.g., sitting at a desk), the motion sensor’s power is reduced to 0.1mA (from 1mA).

The challenge? The MOSFETs had to be small enough to fit on the FPC and flexible enough to bend. They used surface-mount MOSFETs (size: 0.6mm x 0.3mm) placed on a straight section of the FPC—no cracks, no power waste.

If the FPC is the bracelet’s backbone, the rigid-flex PCB is its “brain center.” It combines rigid sections (for mounting components like the MCU) with flexible sections (for connecting to the FPC), and it relies on tiny “micro-holes” (diameters ≤0.2mm) to connect layers of the board. A single off-center hole can break the circuit—so precision is everything.

Rigid-flex PCBs are a mix of rigid FR4 (a fiberglass material) and flexible polyimide (PI). When you drill a micro-hole through both, two problems arise:

- Material Drift: FR4 is hard and dense; PI is soft and flexible. When the drill bit hits PI, it loses resistance and “pulls” off course—like a drill bit slipping on wood vs. metal.

- Heat Damage: Drilling micro-holes generates heat. PI melts at lower temperatures than FR4, so too much heat can warp the flexible section, throwing the drill off track.

In 2022, a factory in Vietnam (working with Maria’s company) faced this exact issue. They were drilling 0.15mm holes in rigid-flex PCBs for a smart bracelet, and 12% of the boards failed because holes were off-center by 30 microns (barely visible, but enough to break connections).

The factory switched to an adaptive drilling machine—a system that adjusts speed and feed rate (how fast the drill moves into the board) based on the material it’s cutting. Here’s how it works:

- When drilling FR4: The machine uses high speed (70,000 RPM) and moderate feed rate (40 mm/min) to cut through the hard material cleanly.

- When it hits PI: Sensors in the machine detect a drop in torque (since PI is softer), so it slows the speed to 50,000 RPM and increases the feed rate to 50 mm/min. This reduces heat and prevents the drill from pulling.

The result? The failure rate dropped from 12% to 2%. “It’s like using a different drill bit for wood and metal—you don’t use the same speed for both,” said Minh, the factory’s lead technician.

PI bends when drilled, so the factory added a temporary support layer to the rigid-flex PCB before drilling. The layer is a thin sheet of aluminum (0.1mm thick) bonded to the PI section—like a “crutch” that keeps it flat.

After drilling, the aluminum is peeled off, leaving perfect micro-holes. Minh explained: “Before, the PI would flex up when the drill hit it, making the hole off-center. With the aluminum, it stays flat—no more drift.” This cut errors by another 30%.

Even with adaptive drilling and support layers, mistakes happen. The factory added a machine vision system—a high-resolution camera that takes a photo of each hole as it’s drilled. AI software measures the hole’s position and diameter; if it’s off by more than 10 microns, the machine stops and alerts a technician.

Before, the factory would test holes after drilling 100 boards—wasting time and materials. Now, errors are caught immediately. “We used to throw away 50 boards a day because of bad holes,” Minh said. “Now it’s 5. That’s a huge saving.”

When you strap on a smart bracelet, you’re not just wearing a device—you’re wearing years of engineering tweaks: an FPC with traces thin enough to save power but strong enough to bend, a rigid-flex PCB with micro-holes drilled to the precision of a Swiss watch.

Maria summed it up best: “Users don’t care about FPCs or micro-holes. They care if the battery lasts and if it doesn’t break. Our job is to make the invisible engineering work for them.”

As wearables get smaller (think smart rings or skin patches), the stakes will only get higher. FPCs will need to be even more power-efficient, and rigid-flex PCBs will need even smaller holes (0.1mm or less). But with adaptive design, smart materials, and real-time monitoring, the next generation of wearables will be slimmer, tougher, and longer-lasting than ever.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.