Last spring, Elena, a production engineer at a European electronics firm, faced a crisis: 30% of 500 shipped wearable health sensors were dead on arrival. “We opened one, and under the microscope, the accelerometer’s solder joint on the flexible zone was cracked,” she said. “It looked fine after assembly—but the second the PCB bent, it broke.”

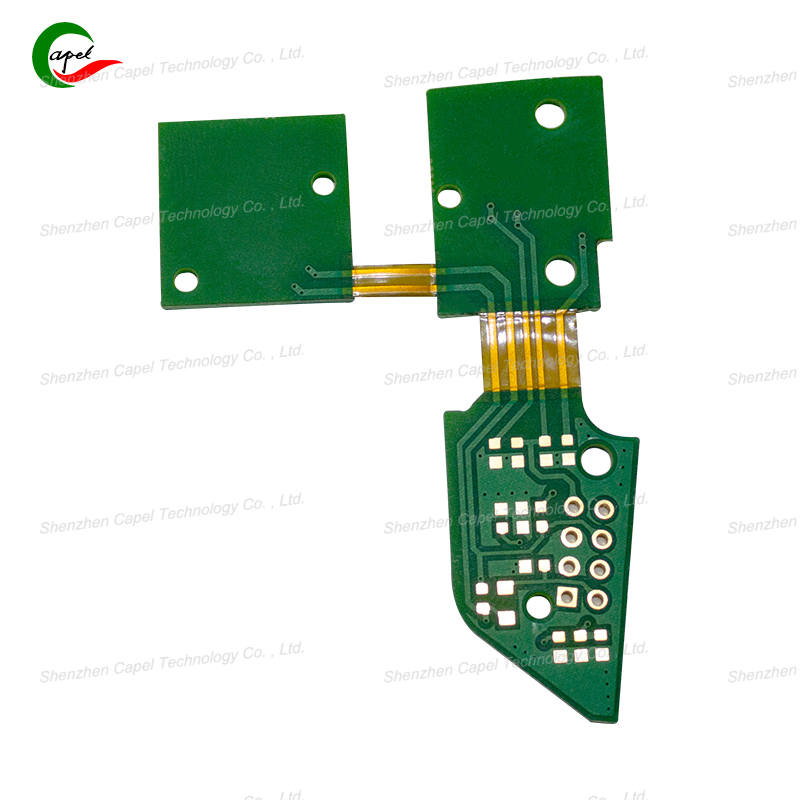

This is the hidden hurdle of rigid-flex PCB surface mount technology (SMT): rigid zones (for microcontrollers, etc.) solder easily, just like traditional PCBs. But flexible zones? They’re tricky. Soldering a rigid component (a resistor, sensor) to a bendable polyimide (PI) layer creates a weak point—one wrong step, and the joint fails when the PCB flexes.

Below, we’ll break down the real challenges of soldering on flexible zones, share engineer stories, and outline proven fixes to keep joints strong.

Traditional rigid PCB SMT works because the board stays flat during reflow. Rigid-flex PCBs change that—flexible PI zones have three traits that ruin soldering:

When heated in a reflow oven, FR4 (rigid) expands at ~13 ppm/°C, while PI (flexible) expands at ~60 ppm/°C—almost 5x faster. Imagine soldering a capacitor (CTE ~7 ppm/°C) to PI: the PI stretches, the capacitor doesn’t, and molten solder cracks as it cools.

“We had foldable phone PCBs where this happened,” said Raj, an Indian process engineer. “Joints looked perfect, but after 10 folds, 20% failed. The mismatch weakened them from the start.”

PI zones are thin (0.1mm) and unsupported—they curl or bow in the oven. This shifts components (so joints are off-center) or creates uneven solder (too much in one spot, too little in another).

Elena’s sensors had this issue: “Oven footage showed the flexible zone curling. The accelerometer shifted 0.1mm—enough to make the joint snap when bent.”

PI pads are smoother than FR4, so solder paste (sticky solder + flux) doesn’t stick well. This causes “tombstoning”: one end of a component (like a 0402 resistor) falls off during reflow, standing up like a tombstone.

“Tombstoning ruined 100 PCBs for us,” Raj said. “The paste slid off the PI pad—no adhesion, no good joint.”

Engineers have tested solutions to these issues—here are the most effective:

Fight thermal mismatch with flexible solder paste (elastic flux residue that stretches with PI) and a slower reflow profile:

-

Preheat: 3–4 minutes to 150°C (slower than rigid PCBs) to align expansion.

-

Peak temp: 230–240°C (5–10°C lower) to reduce PI stretch.

-

Cool: 2–3 minutes to 50°C (slower) to avoid stress.

Elena’s team switched to Henkel’s flexible paste: “Crack rate dropped 80%. The residue bends with the PCB.”

Use temporary or permanent stiffeners (thin aluminum/FR4) to keep PI zones flat during soldering:

-

Temporary: Glued on pre-soldering, peeled off after (great for wearables). “Aluminum stiffeners stopped our curling—no component shift,” Elena said.

-

Permanent: Bonded to zones with components (ideal for non-bending areas, like drone camera sensors).

A Taiwanese firm used permanent FR4 stiffeners: “Joints held up through 500+ flight hours—no failures,” said Mei, their quality manager.

Make PI pads “stickier” with ENIG (Electroless Nickel Immersion Gold)—a rough coating that grabs solder paste. For high temps, use ENEPIG; for low cost, OSP.

Raj’s team added ENIG: “Tombstoning went from 15% to 0.5%. Paste sticks like glue now.” Also, clean PI with plasma first—“Removes oil/dust, instantly boosting adhesion,” Mei said.

A U.S. medical firm made implantable heart monitors with 25% failure rates—solder joints on flexible zones broke when patients moved. Here’s their fix:

-

Thermal mismatch: Sensor (CTE 6 ppm/°C) vs. PI (60 ppm/°C) = cracked joints.

-

Warping: PI curled, shifting tiny 0201 resistors.

-

Poor adhesion: Paste slid off PI pads.

-

Switched to Kester’s flexible solder paste + slow reflow (4min preheat, 235°C peak, 3min cool).

-

Used 0.15mm temporary aluminum stiffeners.

-

Added ENIG + plasma cleaning.

-

Failure rate dropped to 0.8%.

-

Joints survive 10,000+ flexes (5+ years of use).

-

Saved $200k in scrap/rework.

“For medical devices, this isn’t just cost-saving—it’s patient safety,” said Lisa, their engineering director.

Elena, Raj, and Lisa learned this: flexible zone soldering works if you stop treating it like rigid PCB soldering. Use flexible paste, stiffeners, and ENIG—tools tailored to PI’s unique traits.

As rigid-flex PCBs grow in foldables, medical gear, and more, mastering these fixes will be key. Next time you solder a flexible zone, ask: “Am I adapting for PI?” If yes, your joints will hold.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.