Date: 2025-12-10

Hey there! If you're reading this, chances are you already know what a PCB is. But do you really understand how this little green (or sometimes other colors) board became the foundation of our digital world? Or more practically—when your project needs reliable, high-quality PCBs, who should you turn to? I'm from the Kaboer team, and we've been in the PCB industry for over a decade. Today, let's chat about "what's on the board."

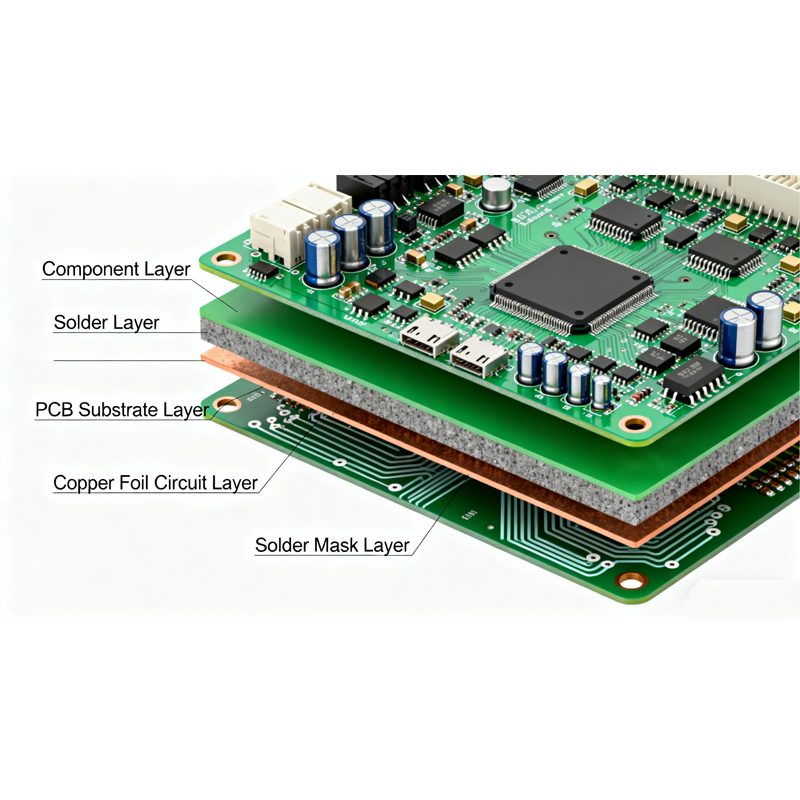

PCB stands for Printed Circuit Board. Simply put, it's the platform that connects a bunch of electronic components, allowing them to "talk" and "cooperate." Imagine your smartphone without a PCB—it would just be a pile of separate chips, resistors, and capacitors with no idea how to communicate. The PCB is their "social network," providing precise pathways for electrical currents and data.

But a PCB is much more than just a connector. Modern PCBs are:

Miniaturization marvels: Today's multilayer boards can pack dozens of circuit layers into a space the size of your thumbnail

Thermal management experts: Well-designed PCBs effectively dissipate heat, protecting sensitive components

Signal integrity guardians: Through careful layout and impedance control, they ensure high-speed signals don't degrade

Mechanical support structures: Providing a solid mounting platform for all kinds of components

We often joke that making PCBs is like high-tech "baking"—it requires precise recipes, strict procedures, and lots of quality control. Here's the simplified process:

Design Phase: Engineers use CAD software to draw circuit diagrams, determine component placement, and route traces. At Kaboer, we recommend clients work with us at this stage—we can help optimize your design, avoid common manufacturability issues, and save you time and money.

Material Preparation: Most PCBs use FR-4 fiberglass substrate, but depending on the application, we also work with high-frequency materials, flexible materials, or metal-clad substrates. Material choice directly impacts the final product's performance and reliability.

Pattern Transfer: The circuit pattern is transferred to the copper layer through photolithography. This step requires extreme precision—a deviation of a few microns in a trace could scrap the entire board.

Etching and Drilling: Unwanted copper is removed, and holes are drilled for mounting and vias. Modern PCBs can have thousands of micro-vias, with diameters thinner than a human hair.

Lamination (Multilayer Boards): Multiple layers are pressed together to form multilayer boards. Alignment precision is critical—we use laser alignment systems to ensure layer-to-layer registration errors are less than 25 microns.

Surface Finish: Different finishes are chosen based on application: HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold), immersion silver, or immersion tin. Each has its pros and cons, and we recommend what's best for your specific needs.

Testing and Inspection: Last but definitely not least, every PCB undergoes automated optical inspection, electrical testing, and sometimes X-ray inspection. At Kaboer, we perform 100% electrical testing, ensuring every board that reaches our customers is flawless.

Consumer Electronics: The most obvious application. Your smartphone likely contains 10-15 different PCBs, including the mainboard, camera modules, display driver boards, etc. Our clients include several leading phone manufacturers. We provide them with High-Density Interconnect (HDI) boards supporting the latest technologies like 5G and foldable displays.

Automotive Industry: Modern cars are data centers on wheels. From engine control units to Advanced Driver Assistance Systems (ADAS), a single vehicle might contain over 150 PCBs. We specialize in automotive-grade PCBs that can withstand extreme temperatures, vibration, and humidity, meeting stringent standards like AEC-Q100.

Medical Devices: Here, reliability is directly tied to life and death. We manufacture PCBs for pacemakers, ventilators, and medical imaging equipment, following the ISO 13485 medical device quality management system to ensure every board is perfect.

Industrial Equipment: Factory automation, robotics, and energy management systems need PCBs that can work reliably long-term in harsh industrial environments. We use heavy copper foils, special coatings, and high-Tg materials to ensure these boards can handle the challenge.

IoT and Wearables: Miniaturization and low power consumption are key here. We manufacture flexible PCBs and rigid-flex boards for smartwatches, health monitors, and various sensors.

Aerospace and Defense: Absolute reliability in extreme environments. We provide PCBs for these applications that comply with AS9100 standards, using special materials and processes to ensure they function even under extreme conditions.

High-Density Interconnect (HDI): Using micro-vias, buried vias, and blind vias to achieve more complex interconnections in smaller spaces. This is crucial for smartphones, tablets, and other compact devices.

Flexible PCBs: Circuit boards that can bend, fold, or even stretch, opening new possibilities for wearables and compact electronics.

High-Speed Materials: As data rates climb to 10Gbps and beyond, traditional FR-4 materials can't keep up. We offer a range of low-loss materials supporting next-generation communication standards.

Embedded Components: Resistors, capacitors, and even chips embedded within the PCB itself, further reducing size and improving performance.

Advanced Thermal Management: For high-power applications, we provide metal-clad substrates, thermal vias, and special thermally conductive materials to ensure heat is effectively dissipated.

Let me share a real example: A client came to us with a beautiful design that was yielding only 65% with their previous supplier. After analysis, we identified several manufacturability issues with the design itself—pads too small, insufficient clearances, no consideration for thermal expansion. We redesigned and optimized it, increasing yield to over 98% while reducing manufacturing costs by 20%. That's the value of expertise.

At Kaboer, we believe a good PCB supplier should:

Offer Design Support: The best suppliers get involved at the design stage. Our engineering team can review your design, identify potential issues, and suggest improvements. This can prevent costly late-stage modifications and production delays.

Have Strong Manufacturing Capabilities: We've invested in the latest equipment, including laser drillers, automated optical inspection systems, and flying probe testers. But what we're more proud of is our process expertise—knowing how to adjust parameters for the best results.

Maintain Strict Quality Standards: We're certified to ISO 9001, IATF 16949 (automotive), and ISO 13485 (medical). More importantly, we've built a comprehensive quality control system with checkpoints at every step, from raw material inspection to final shipment.

Provide Transparent Communication: We understand it can be unsettling to hand off a critical component to someone else. So we provide regular progress updates, quick responses to inquiries, and honest communication when issues arise.

Be Flexible and Responsive: Whether you need 10 prototypes or 100,000 production units, we can handle it. Our supply chain management ensures we can accommodate demand fluctuations and deliver on time.

When evaluating potential suppliers, don't just ask about price and lead time. Ask these questions:

Can you provide design review and optimization suggestions?

How do you handle impedance control requirements?

For multilayer boards, can you provide stack-up design and simulation support?

What quality certifications does your factory hold?

How do you manage material traceability?

When problems occur, how do you handle and communicate them?

What test and inspection reports can you provide?

At Kaboer, we have clear answers to all these questions, and we encourage potential clients to visit our factory to see our capabilities firsthand.

Smaller But Smarter: As IoT and wearables proliferate, demand for miniaturized PCBs will continue growing, but these boards will integrate more functionality.

Sustainability: Eco-friendly materials, recyclability, and energy-efficient manufacturing processes are becoming increasingly important. We're investing in green technologies to reduce our products' environmental footprint.

Higher Integration: PCBs will increasingly integrate antennas, sensors, and other functions, becoming true "system-in-package" solutions.

Faster Data Rates: With 5G and future 6G, demand for PCBs supporting extremely high frequencies will increase.

The PCB might not be the flashiest part of your product, but it's absolutely one of the most critical. A poorly designed or manufactured PCB can cause the entire product to fail, resulting in significant financial and reputational damage.

That's why choosing a PCB supplier isn't a price-based commodity purchase but a capability- and trust-based partnership selection. At Kaboer, we don't just manufacture PCBs; we provide solutions. We take the time to understand your application, challenges, and goals, then use our expertise to help you achieve them.

So next time you have a project that needs PCBs, remember: this little board carries your entire product. Make sure it gets the attention and expertise it deserves.

Whether you're designing the next world-changing device or just need a reliable production partner, Kaboer is ready to help. Contact us, and let's discuss how to turn your ideas into reality. With our extensive experience and global client base, we might just have the solution you need.

Remember, the best products are built on the best foundations. And the PCB is that foundation.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..