Date: 2025-12-10

Hey folks in the engineering and product design world! Let’s talk about a topic that seems simple but is actually critical—standard PCB thickness. I bet you’ve probably never lost sleep over this spec, but you might start after reading this. At Kaboer, we have this conversation with customers daily because it directly impacts product performance, cost, and reliability.

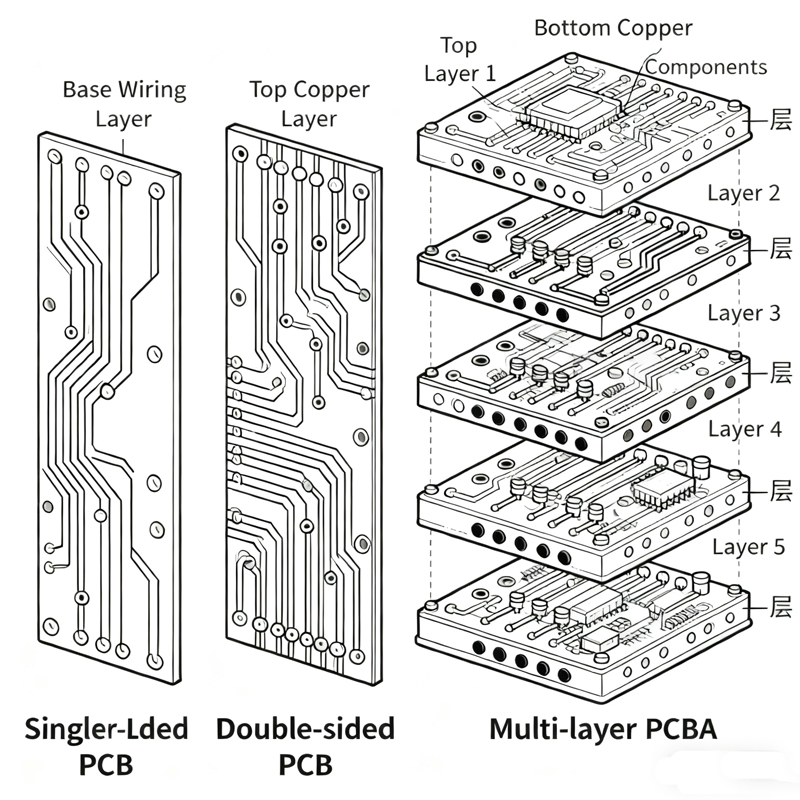

Let’s start with the basics. When people talk about PCB thickness, most think about the base material thickness—that insulating layer, usually FR-4 fiberglass. But honestly, the finished PCB thickness actually includes more: the base material, copper layers (maybe multiple), solder mask, silkscreen, even the surface finish.

In the industry, when we say “standard thickness,” we’re usually referring to 1.6mm (about 0.063 inches). That number has been around for decades and has become the default. But why? Because it hits a sweet spot between strength, cost, and availability.

Mechanical Stability: Boards that are too thin can bend or break, especially during assembly or under physical stress. Too thick? They might eat up your precious space, especially in those ever-shrinking devices.

Electrical Performance: Thickness affects impedance control, signal integrity, and heat dissipation. High-frequency applications? That demands even tighter thickness consistency.

Assembly Compatibility: Connectors, sockets, and enclosures are often designed for specific board thicknesses. If you deviate too much, you might run into fit issues.

Cost Considerations: Standard thickness means standard materials, standard processes, and naturally, lower costs. Special thickness? That’s a special price tag.

0.8mm (about 0.031 inches):

A favorite for slim electronics. Think ultra-thin smartphones, wearables (like fitness trackers), credit-card-sized gadgets. It’s sturdy enough for daily use but keeps your product sleek. At Kaboer, we make a lot of boards at this thickness for consumer electronics clients, but with one key piece of advice: for larger boards, you might need additional support or stiffeners.

1.0mm (about 0.039 inches):

A great middle ground. More robust than 0.8mm but not too thick. Common in compact devices, IoT sensors, some automotive modules, and industrial controllers. If you’re unsure what to pick, 1.0mm is often a safe bet.

1.2mm (about 0.047 inches):

Gaining popularity where more mechanical strength is needed without going full 1.6mm. Some mid-sized consumer devices, many industrial boards, and specific automotive applications go for this. At Kaboer, we’re seeing more clients move from 1.6mm to 1.2mm to save space without sacrificing too much strength.

1.6mm (about 0.063 inches):

The real “industry veteran.” Why is it so common? Because it offers great strength, good manufacturability, and compatibility with most standard connectors. From power boards and LED lighting to large industrial controllers and plenty of automotive electronics, 1.6mm is almost everywhere. At Kaboer, we stockpile materials at this thickness, so lead times are usually the shortest and costs most competitive.

2.0mm (about 0.079 inches) and above:

When you need real ruggedness, this is where you go. High-power devices, heavy industrial equipment, boards that need to withstand vibration and shock (think agricultural or construction machinery), and certain military/aerospace applications. Thickness can go up to 3.2mm or more. But note, as thickness increases, so do drilling and plating challenges.

When you step into 4-layer, 6-layer, 8-layer, or more, thickness isn’t just about the base material anymore. You need to consider:

The thickness of each dielectric layer

Copper layer thickness (usually 0.5 oz, 1 oz, or 2 oz)

Layer-to-layer alignment

At Kaboer, we often help clients optimize their stack-up. For example, a 1.6mm 6-layer board can have multiple “stack-up configurations”—different combinations of dielectric thicknesses. Which one you choose depends on your signal integrity needs, thermal requirements, and manufacturing capabilities. This is where experience really pays off.

Ask yourself these questions:

What are the mechanical requirements?

How large is the board? Larger boards often need to be thicker to prevent flexing.

Will it face vibration or shock?

Are there heavy components on it?

Will it be mounted in a rack or enclosure?

What are the electrical requirements?

Any impedance control needs? (Thickness is key in impedance calculations)

Is it high power? Need better heat dissipation?

High-frequency signals?

What are the assembly and space constraints?

How much room is in the enclosure?

What types of connectors are used? (Some have strict board thickness limits)

Through-hole or surface-mount assembly?

What are the cost considerations?

Standard thickness is almost always cheaper

Special thickness might mean longer lead times and higher costs

At Kaboer, we follow a simple rule: Stick to standard thickness unless you have a really good reason not to. That advice has saved clients countless hours and dollars.

“Thicker is always stronger”: Not necessarily. A well-designed thin board with smart component placement and mechanical support can be plenty strong.

“Thickness doesn’t affect electrical performance”: Wrong. Thickness impacts impedance, crosstalk, and heat dissipation—all critical for high-speed or high-power circuits.

“I can specify any thickness I want”: Technically yes, but economically maybe not wise. Special thicknesses can mean special material orders, longer lead times, and higher costs.

“All 1.6mm boards from all suppliers are the same”: Absolutely not. Material quality, manufacturing processes, and consistency controls make a world of difference. That’s where suppliers like Kaboer stand out—we make sure every board you get meets spec.

With years of serving global clients, we’ve developed a system:

Early Design Consultation: Reach out before your layout is frozen. We can review your design and advise on thickness, considering mechanical, electrical, and manufacturability factors. One preventive conversation can avoid costly changes later.

Material Selection Guidance: Different applications need different materials. High-speed digital? We’d suggest low-loss materials. High-temperature environment? High-Tg materials might be the answer. We help you choose the right material for your thickness needs.

Stack-up Design Optimization: For multilayer boards, we provide detailed stack-up drawings and recommendations, making sure signal integrity, power integrity, and manufacturability are all considered.

Seamless Prototype-to-Production Transition: We ensure your prototypes and production boards use the same thickness and materials, avoiding surprises.

Rigorous Quality Control: We measure thickness on every material batch and monitor it throughout production. We aim for ±10% tolerance, even tighter for critical applications.

Real Example: Recently, a client came to us with an 8-layer board design where they’d specified 1.2mm thickness. After review, we found their impedance requirements couldn’t actually be met at that thickness. We suggested moving to 1.6mm with an adjusted stack-up, meeting their electrical needs with only a slight increase in overall thickness. They avoided potential post-production issues.

Don’t forget, the final board thickness also includes surface finish (like ENIG, HASL, or immersion tin) and solder mask. While these usually add just microns, in ultra-precision applications, every micron counts.

The rise of mobile devices and wearables is driving demand for thinner PCBs. But at the same time, reliability expectations are higher. At Kaboer, we’ve invested in advanced equipment that can handle thinner materials while maintaining top quality standards.

We’re also seeing interest in “mixed-thickness” boards—different areas of the same board with different thicknesses. It’s challenging, but with precision routing and lamination techniques, we can make it happen.

PCB thickness might seem like just a number on a spec sheet, but it matters. The right choice can make your product more reliable, better performing, and cheaper to build. The wrong choice can lead to assembly headaches, field failures, or unnecessary costs.

That’s why partnering with an experienced provider is so valuable. At Kaboer, we don’t just take orders—we provide solutions. We understand how thickness affects every aspect of your design, and we use that knowledge to help you get the best result.

So next time you’re kicking off a new project, think about PCB thickness early. Better yet, reach out to us and let’s discuss. With our experience serving thousands of clients worldwide, we might just have the insight you need.

Remember, the best designs are those that meet both technical requirements and real-world manufacturing constraints. And choosing the right PCB thickness is at the heart of that balance.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..