Last week, I opened my old wireless charger to fix a loose wire—and found a small green board covered in tiny metal lines. I’d seen this “board” in my phone, laptop, and even my coffee maker, but I never knew what it was. My cousin, who fixes electronics, called it a PCB. “It’s the reason your devices work without being a mess of wires,” he said.

Curious, I looked into it—and realized PCBs are the unsung heroes of modern tech. This guide breaks down what PCBs are, what they do, and the different types—no jargon, just simple, real stuff.

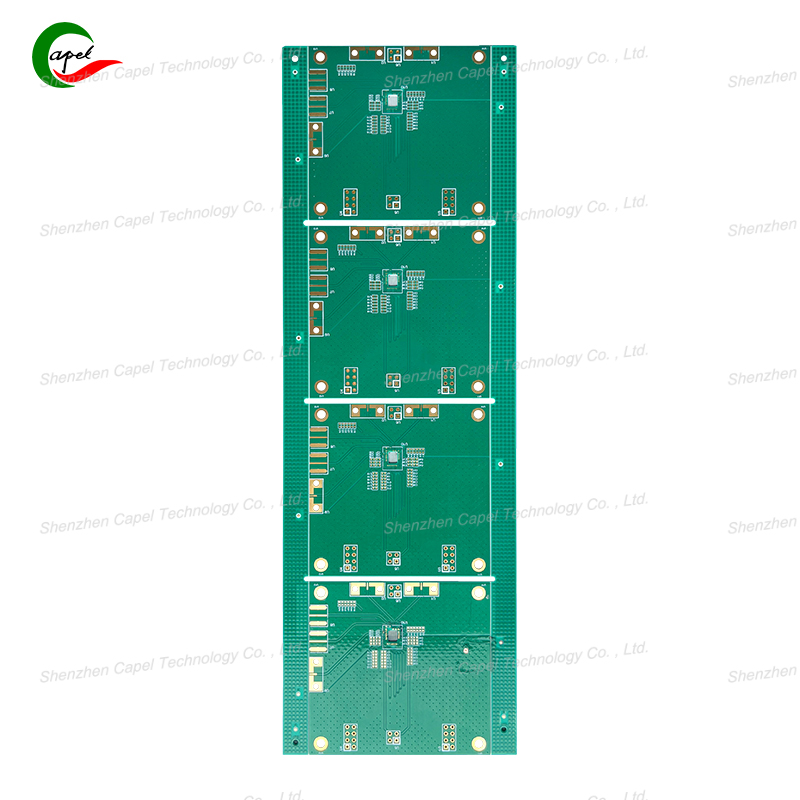

PCB stands for Printed Circuit Board—a flat board that connects and powers the parts of your devices. Think of it like a “road map” for electricity:

- The board itself (usually green) is made of non-conductive material (like plastic) to keep electricity from shorting.

- Thin copper “traces” (the shiny lines) act as roads, carrying power and data between components (resistors, chips, etc.).

Without a PCB, your phone would be a tangled pile of wires—impossible to fit in your pocket.

PCBs have three big jobs that make your devices work:

They link parts like your phone’s camera, battery, and screen. Instead of separate wires for each part, the PCB’s traces do the work—neat and reliable.

They send electricity from the battery to every component. For example, your laptop’s PCB makes sure the keyboard, screen, and processor all get the right amount of power.

The non-conductive board and sealed traces keep components safe from water, dust, and drops. My cousin once fixed a phone that fell in a puddle—“The PCB was sealed, so it still worked,” he said.

Not all PCBs are the same—they’re designed for how a device is used:

- What they are: Hard, inflexible boards (like the one in my wireless charger).

- Where you’ll find them: Laptops, TVs, coffee makers—devices that don’t need to bend.

- Why they matter: Cheap to make and durable for stationary devices.

- What they are: Thin, bendable boards made of soft plastic (like the one in my smartwatch).

- Where you’ll find them: Foldable phones, fitness trackers, medical monitors—devices that curve or move.

- Why they matter: They can bend 10,000+ times without breaking—something rigid PCBs can’t do.

- What they are: A mix of rigid and flexible parts (like the ones in drones).

- Where you’ll find them: Drones, cameras, car electronics—devices that need both stability and flexibility.

- Why they matter: The rigid part holds sensitive components (like chips), while the flexible part fits into tight, curved spaces.

You might never see a PCB, but you use one every day:

- They make devices small (think wireless earbuds instead of bulky headphones).

- They keep devices reliable (no loose wires to break).

- They let devices do more (multi-layer PCBs power phones that take photos, stream videos, and connect to Wi-Fi at once).

Now, when I look at my phone or laptop, I think about the PCB inside. It’s not flashy, but it’s the reason my devices fit in my pocket, work when I need them, and do all the things I love.

Next time you use a device, take a second to appreciate the PCB—it’s the hidden star that makes modern tech possible.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.