Last harvest, Carlos, an Iowa farm manager, watched his $20k precision sprayer die mid-field. A rainstorm had seeped into the sensor module, frying its rigid PCB. “We lost three days of spraying waiting for a replacement,” he said.

This is common in smart agriculture. Today’s farms use sensors, drones, and irrigation controllers—all relying on PCBs. But outdoor farms are harsh: extreme temps, moisture, dust, and vibration. Traditional rigid PCBs fail here, but FPCs (Flexible Printed Circuits) and rigid-flex boards work. Below, we’ll break down their strengths and how to choose.

Rigid PCBs can’t handle four farm threats:

- Extreme Temps: FR4 cracks when paired with components that expand differently (e.g., sensors in -25°C winters).

- Moisture: Rain/dew seeps in, corroding traces (Carlos’s sprayer issue).

- Dust: Debris clogs vents, causing overheating (irrigation controllers fail often).

- Vibration: Tractor/sprayer shakes loosen connectors (drone scanners lose signal).

FPCs (thin, flexible PI-based circuits) excel in specific cases:

FPCs bend with shakes, protecting solder joints. Maria, an ag tech engineer, switched soil sensors to FPCs: “Failure rate dropped from 20% to 2%—no more cracked joints from tractor vibration.”

FPCs (0.1mm thick) fit small, sealed enclosures (keeping dust out) and cut drone weight. Carlos’s drone now flies 35 mins/charge (vs. 20 mins with rigid PCBs).

- Tractor sensors, drones, portable soil testers.

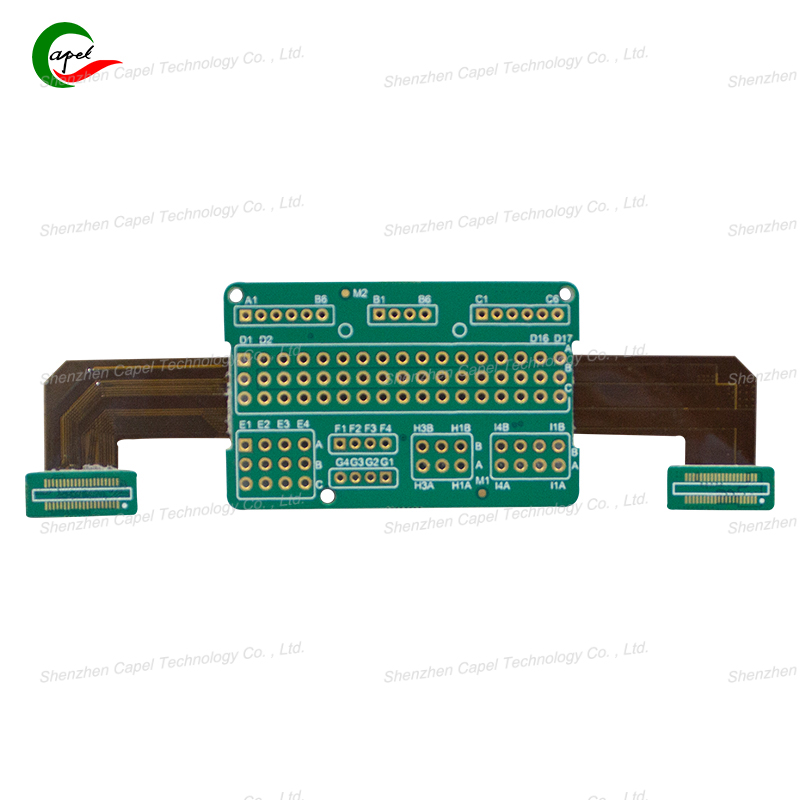

Rigid-flex (FR4 + flexible PI) balances stability and flexibility:

Rigid sections hold microchips; flexible parts absorb vibration. Maria’s sprayer control modules now use rigid-flex: “No more failures—microcontrollers stay stable, sensors bend with shakes.”

PI sections handle -30°C to 50°C swings; fewer connectors mean less dust. Raj’s Indian farm uses rigid-flex for irrigation controllers: “Works year-round—no dust clogs, no cracked joints.”

- Precision sprayers, year-round irrigation, harvester yield monitors.

Ask three questions:

- Need lightweight/compact? FPCs (drones, portables).

- Need stable components? Rigid-flex (sprayers, yield monitors).

- Main threat: vibration vs. temps? FPCs (vibration); rigid-flex (temps/dust).

Case Study: A Brazilian farm cut failures from 20% to 2% by choosing FPCs for sensors/drones and rigid-flex for sprayers. Yields rose 8%—all from better PCBs.

Rigid PCBs aren’t built for farms. FPCs and rigid-flex handle moisture, vibration, and temps—saving time and money. Next time you pick a PCB, ask: “Can it survive the field?” If not, choose FPC or rigid-flex. Your crops will thank you.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.