Last year, I was a design engineer at a consumer electronics firm working on a foldable phone. We’d shipped 10,000 units with rigid-flex PCBs from Batch A—all worked perfectly. But when Batch B arrived, disaster struck: 80% of the PCBs didn’t fit the phone’s frame. The flexible section was 0.2mm thicker than Batch A, and the rigid zones were misaligned by 1mm. We had to halt production, rework the PCBs, and delay shipping—costing the company $50,000 in downtime.

The problem? No design standardization. Batch A was made by a supplier in Taiwan, Batch B by one in China. Each used different 基材 thicknesses, flex zone layouts, and measurement tolerances. What we thought was “the same PCB” was actually two different designs—and it nearly ruined our product launch.

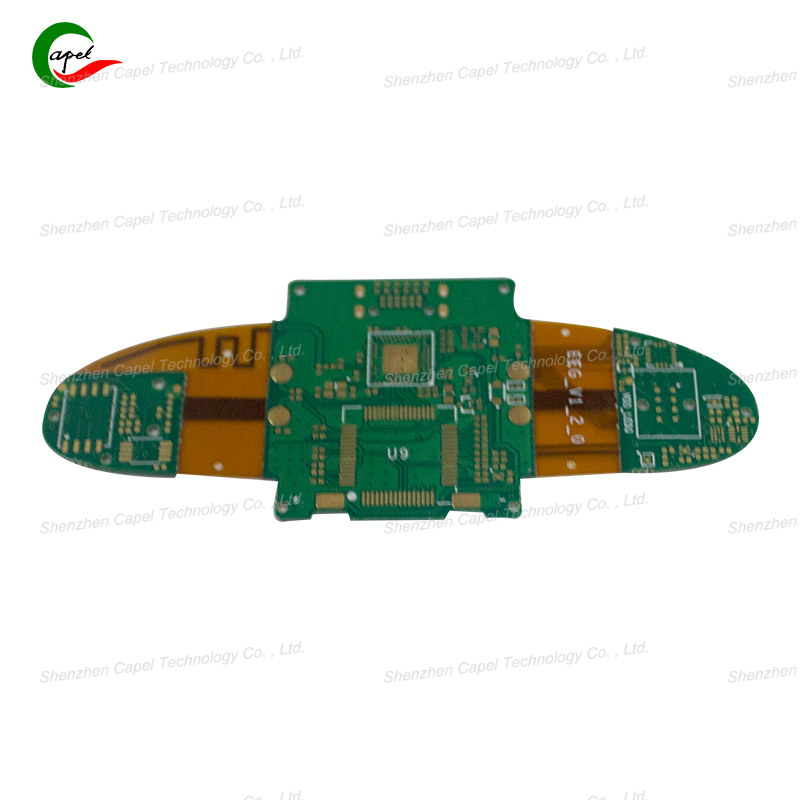

This is a common nightmare with rigid-flex PCBs. Unlike rigid PCBs (which have well-established standards), rigid-flex designs often rely on “custom” choices—supplier-specific materials, vague tolerances, or unrecorded design tweaks. This leads to compatibility issues across batches: PCBs that don’t fit, components that won’t solder, or circuits that fail.

In this article, I’ll share how we fixed our batch compatibility problem, break down the key areas to standardize in rigid-flex design, and explain how small, consistent choices can save you time, money, and headaches.

Most teams blame suppliers for batch issues—but the real problem often starts with vague or missing design standards. Here are the three biggest reasons compatibility fails:

Rigid-flex PCBs use a mix of materials: FR4 for rigid zones, PI (polyimide) for flexible zones, and adhesives to bond them. If your design only says “FR4” and “PI” without details (e.g., thickness, grade), suppliers will use what’s cheapest or most available.

“We specified ‘PI film’ for our flexible zones,” said Raj, a quality manager at an automotive parts firm. “Batch A used 0.075mm DuPont PI; Batch B used 0.125mm generic PI. The thicker PI made the PCB too stiff—our robots couldn’t bend it into the car’s frame.”

Tolerances (allowable variations in size) are critical for rigid-flex PCBs—especially for flex zone dimensions and rigid-flex alignment. If your design says “flex zone width: 5mm” without a tolerance (e.g., ±0.1mm), a supplier might make it 5.2mm in one batch and 4.8mm in the next.

Our foldable phone PCB had this issue: we didn’t specify a tolerance for the flexible section’s thickness. Batch A was 0.3mm (within our unspoken “ideal”), Batch B was 0.5mm—too thick to fit the frame.

It’s common to make small tweaks during the first batch (e.g., adjusting a flex zone’s curve to fix bending). But if those tweaks aren’t documented in a standard, the next supplier (or even the same one) won’t know to copy them.

Maria, an engineer at a medical device firm, saw this: “We tweaked Batch A’s rigid zone placement to fit our sensor. But we didn’t update the design file—Batch B used the original placement, and the sensor wouldn’t mount. We had to scrap 2,000 PCBs.”

Fixing batch issues isn’t about “controlling suppliers”—it’s about creating clear, detailed standards they can follow. Below are the four most important areas to standardize, with examples from our fix.

The first step is to standardize every material in the rigid-flex PCB, including grades, thicknesses, and even suppliers (if critical).

- Rigid FR4: Specify grade (e.g., FR4-TG130), thickness (e.g., 1.6mm), and copper weight (e.g., 1oz).

- Flexible PI: Specify brand/grade (e.g., DuPont Kapton HN), thickness (e.g., 0.075mm), and copper weight (e.g., 0.5oz).

- Adhesives: Specify type (e.g., acrylic), thickness (e.g., 0.05mm), and CTE (e.g., 50 ppm/°C) to match PI/FR4.

We used to say: “FR4 for rigid zones, PI for flex zones.” Now we say: “Rigid zones: FR4-TG130, 1.6mm thick, 1oz copper; Flex zones: DuPont Kapton HN, 0.075mm thick, 0.5oz copper; Adhesive: 3M 9495LE, 0.05mm thick.”

Result: Batch B2 (after standardization) had identical material thicknesses to Batch A—no fit issues.

Tolerances tell suppliers how much variation is acceptable. For rigid-flex PCBs, focus on tolerances that affect fit and function:

- Flex zone dimensions: Width (e.g., 5mm ±0.1mm), thickness (e.g., 0.3mm ±0.05mm).

- Rigid-flex alignment: Distance between rigid zones (e.g., 20mm ±0.05mm).

- Hole positions: For connectors or components (e.g., 10mm ±0.02mm from edge).

We added tolerances to every key dimension: “Flex section thickness: 0.3mm ±0.05mm; Rigid zone alignment: 18mm ±0.05mm.”

Supplier feedback: “Now we know exactly what to make—no more guessing if 0.35mm is okay.”

Flex zones are the most unique part of rigid-flex PCBs—and the most likely to vary between batches. Standardize their design to ensure consistent bending and durability.

- Bend radius: Minimum radius (e.g., 3x flex thickness—so 0.9mm for 0.3mm flex).

- Strain relief loops: Size (e.g., 10mm wide) and placement (e.g., 5mm from rigid-flex transition).

- Cover layers: Material (e.g., PI) and thickness (e.g., 0.025mm) to protect flex traces.

We used to design flex loops “by eye.” Now we specify: “Flex zone bend radius: ≥0.9mm; Strain relief loop: 10mm wide, centered on flex zone; Cover layer: 0.025mm PI on both sides.”

Result: Batch B2’s flex zones bent the same way as Batch A—no stiffness issues.

Even the best standards are useless if no one can find them. Create a single, accessible “Rigid-Flex Design Standard” document that includes:

- Material specs (with links to supplier datasheets).

- Dimensional drawings with tolerances (in PDF and CAD formats).

- Photos of acceptable/unacceptable PCBs (e.g., “good flex loop vs. too tight”).

- Test requirements (e.g., “flex 100x without cracking”).

We uploaded the standard to our shared drive, sent it to all suppliers, and held a 30-minute training call. We also added a “standards check” step in our design review process.

Maria’s team did the same: “Now every engineer and supplier uses the same document. Batch compatibility went from 60% to 99%.”

Standardization doesn’t mean “policing” suppliers—it means partnering with them to meet your needs. Here are three practical ways to enforce standards:

A “golden sample” is a physical PCB from a successful batch (like our Batch A) that meets all your standards. Send it to suppliers with your design docs—they can measure and compare their PCBs to it.

“We sent golden samples to our new Chinese supplier,” Raj said. “They used it to adjust their process—Batch B matched perfectly.”

When new batches arrive, test them against your standards before using them. Focus on critical checks:

- Material thickness (use a caliper).

- Dimensional tolerances (use a coordinate measuring machine, or CMM).

- Flex durability (flex 50x and check for cracks).

“We used to skip incoming inspection—now we test 10 PCBs per batch,” I said. “We caught a 0.1mm flex thickness issue in Batch B1 before it reached production.”

If a supplier struggles to meet your standards, work with them to fix the issue—don’t just switch suppliers. For example, if a supplier can’t hit your flex tolerance, help them adjust their lamination process.

“Our Taiwanese supplier struggled with rigid zone alignment,” Maria said. “We shared our CMM data with them, and they adjusted their drilling machine. Now they meet our tolerance every time.”

After 3 months of standardization, here’s what changed for our foldable phone PCB:

The biggest win? We now use two suppliers (Taiwan and China) interchangeably—their PCBs are identical. “We no longer worry about which supplier ships which batch,” our production manager said. “They all meet the standard.”

Our $50k mistake taught us that rigid-flex PCB compatibility isn’t about “perfect” designs—it’s about consistent ones. Vague specs lead to variable PCBs; clear standards lead to identical batches.

The key steps are simple:

- Standardize materials, tolerances, and flex designs—leave no guesswork.

- Document everything in an easy-to-use guide.

- Partner with suppliers to meet standards (use golden samples and inspection).

As rigid-flex PCBs become more common in foldables, wearables, and cars, standardization will only grow in importance. The teams that get it right won’t just save money—they’ll build products their customers can trust, batch after batch.

Next time you design a rigid-flex PCB, ask: “Would another supplier make this exactly the same way?” If not, it’s time to standardize. Your production line (and your budget) will thank you.