Date: 2025-12-29

PCBA Manufacturing – the industrial process of Printed Circuit Board Assembly – is the critical transformation phase where a bare PCB becomes a functional electronic heart. It encompasses the entire value chain from component procurement and kitting to precision soldering, rigorous testing, and final integration. For global OEMs, EMS partners, and hardware startups, mastering PCBA manufacturing is not just about assembly; it’s about ensuring product reliability, managing supply chain risk, and achieving scalable, cost-effective production.

This definitive guide explores the intricacies, technologies, and strategic considerations of modern PCBA manufacturing.

While assembly is the core action, PCBA Manufacturing represents a full-service ecosystem:

PCB Fabrication: Manufacturing the bare board based on Gerber files.

Component Sourcing & Supply Chain Management: Procuring all parts (from resistors to advanced ICs) against your BOM, managing shortages, lifecycle issues, and counterfeit prevention.

Assembly Processes: Applying both Surface Mount Technology (SMT) and Through-Hole Technology (THT).

Value-Added Services: Conformal coating, potting, system integration (box build), and fulfillment.

Testing & Quality Assurance: Guaranteeing the assembled unit meets all electrical, functional, and reliability specifications.

The Strategic Outcome: A turnkey PCBA partner delivers a ready-to-integrate module, while a consignment model focuses on labor and expertise. The choice fundamentally impacts your operational complexity and risk.

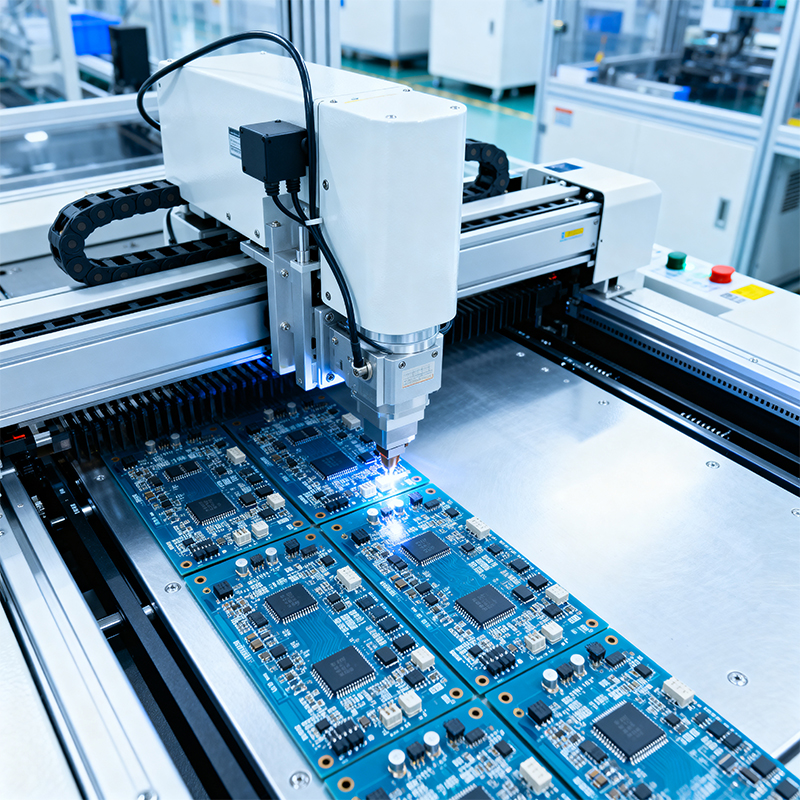

A state-of-the-art facility operates as a seamless, digitally controlled pipeline.

Phase 1: Pre-Production Engineering – The Foundation for Success

Advanced-DFM/A Analysis: Expert engineers analyze your design files not just for manufacturability, but also for Assembly (DFA) and Testability (DFT). They provide actionable feedback on component selection, layout, thermal management, and test point access to prevent costly post-production fixes.

Supply Chain Engagement & Risk Mitigation: For turnkey projects, the manufacturer performs a detailed BOM scrub, identifying long-lead, obsolete, or high-risk components. They propose qualified alternates and secure inventory, often leveraging collective buying power.

Phase 2: SMT Assembly – Precision at High Speed

Solder Paste Printing & 3D SPI: A laser-cut stencil and automated printer deposit solder paste. An inline 3D Solder Paste Inspector (SPI) measures the volume, height, and area of every paste deposit, rejecting boards with insufficient or excessive paste to prevent defects at the source.

High-Speed, Flexible Component Placement: Modern lines combine ultra-fast chip shooters (placing up to 250,000 passive components per hour) with precision flexible placers for BGAs, QFNs, and connectors. Vision systems and force sensors ensure micron-level accuracy.

Controlled Atmosphere Reflow Soldering: The board travels through a multi-zone nitrogen-inerted reflow oven. A meticulously profiled thermal curve ensures optimal solder joint formation for all component types while minimizing thermal stress and oxidation.

Phase 3: THT, Hybrid Assembly & Post-Solder Processes

Automated Through-Hole Insertion: For mixed-technology boards, selective robotic inserters or axial/radial assembly machines place leaded components.

Advanced Soldering: Wave soldering for high-volume THT, or selective soldering robots for precise, localized soldering of connectors or sensitive components, eliminating thermal exposure to nearby SMDs.

Conformal Coating & Potting: Automated spray, selective brush, or dipping systems apply acrylic, silicone, or urethane coatings for protection against moisture, chemicals, and vibration. Potting with epoxy may be used for high-stress environments.

Phase 4: Comprehensive Validation & Final Integration

Automated Optical Inspection (AOI): Post-reflow, 2D and 3D AOI systems compare the board to a golden standard, flagging tombstoning, bridging, polarity, and part presence defects.

X-Ray Inspection (AXI): Essential for hidden solder joints, such as those under Ball Grid Array (BGA) or Land Grid Array (LGA) packages, detecting voids, head-in-pillow, and alignment issues.

Electrical & Functional Testing: This ranges from Flying Probe and In-Circuit Test (ICT) for basic connectivity and component verification, to full Functional Test (FCT) where the board operates in its simulated end-use environment, validating software, firmware, and system-level performance.

System Integration (Box Build): The final PCBA is assembled into its enclosure, connected to displays, wiring harnesses, and other sub-assemblies, tested as a complete unit, and packaged for shipment.

Choosing a manufacturer is a strategic decision. Beyond basic capability, evaluate:

Technological Sophistication: Look for capabilities like 01005 component placement, micro-BGA assembly (<0.3mm pitch), press-fit technology, and automated optical alignment for rigid-flex assemblies.

Quality Certifications & Standards: Compliance with ISO 9001, IATF 16949 (Automotive), ISO 13485 (Medical), and adherence to IPC-A-610 Class 2/3 workmanship standards are non-negotiable for serious manufacturers.

Supply Chain Resilience & Transparency: Assess their component sourcing network, inventory management systems, and ability to provide real-time supply chain visibility and component obsolescence management.

Scalability & Flexibility: Can they efficiently handle your New Product Introduction (NPI) with flexible lines and then transition seamlessly to dedicated high-volume production lines without quality loss?

Engineering Partnership: The best partners act as an extension of your team, providing proactive consultancy during the design phase to optimize cost, reliability, and time-to-market.

Understanding what you pay for is crucial. Costs are typically broken down into:

Non-Recurring Engineering (NRE): One-time costs for stencil creation, test fixture design & programming, and process setup.

Recurring Costs:

Materials: PCBs and components (the largest cost block in turnkey).

Assembly Labor: Direct labor for machine operation, manual assembly, and inspection.

Overhead: Facility, equipment depreciation, and utilities.

Value-Add Services: Coating, testing, box build, and logistics.

Volume is the Key Driver: Unit cost decreases significantly with volume due to amortized NRE and improved material pricing.

Miniaturization & Advanced Packaging: Driving the need for SiP (System-in-Package) and heterogeneous integration assembly.

Industry 4.0 & Smart Factories: Utilization of IoT sensors on production lines for real-time process monitoring, predictive maintenance, and data-driven yield optimization.

Sustainability: Growing demand for lead-free and halogen-free processes, recyclable materials, and energy-efficient manufacturing.

Automation & Robotics: Increased use of collaborative robots (cobots) for material handling and complex final assembly tasks.

In a landscape where PCBA manufacturing is often fragmented across multiple subcontractors, Kaboer offers a fundamentally different proposition: vertical integration and direct accountability through our owned and operated factory in Shenzhen, China.

Why Our Integrated Factory Model Delivers Unmatched Value:

End-to-End Process Sovereignty & Quality Assurance: We control the entire production environment—from the temperature/humidity-controlled SMT floor to the chemical management in coating stations. This allows us to implement and audit stringent process controls (CPk) at every step, ensuring unparalleled consistency. Our investment in SPI, 3D AOI, and high-resolution X-ray is not for audit but for real-time process correction, achieving first-pass yields that dispersed supply chains cannot match.

Deep-Stack Engineering Collaboration: Our engineers engage at the schematic stage. We conduct thermal and signal integrity simulations on your layout, recommend optimal component substitutions for supply or performance, and design custom test fixtures that cover 95%+ fault coverage. This partnership turns manufacturing from a cost center into a competitive advantage.

Supply Chain Agility as a Core Competency: Located in the global electronics epicenter, our procurement team has direct relationships with top-tier distributors and component manufacturers. We don’t just buy parts; we actively manage your BOM for multi-sourcing, lifecycle forecasting, and last-time-buy recommendations, insulating your project from market volatility.

Transparent, Scalable Operational Model: From your first 25-unit engineering build to a 250,000-unit monthly ramp, you work with the same integrated team. Our NPI-dedicated lines allow for agile prototyping, while our high-speed volume lines are calibrated for efficiency. This seamless scalability eliminates the painful and risky handoff between a prototype shop and a mass-production house.

Risk Mitigation and Intellectual Property Security: Operating a single, audited facility under strict confidentiality agreements provides a more secure environment for your IP than multi-tiered subcontracting. Our comprehensive in-house capability reduces external dependencies, mitigating risks related to quality, communication, and scheduling.

For global innovators who view manufacturing as a strategic pillar, not a commodity service, Kaboer provides the control, expertise, and partnership necessary to win in competitive markets. Let us show you how integrated PCBA manufacturing is done.

Q1: What is the difference between Class 2 and Class 3 assembly per IPC-A-610?

A: Class 2 (Dedicated Service Electronic Products) is for devices where extended reliability is desired but not critical (e.g., consumer electronics, general computing). Class 3 (High-Performance Electronic Products) is for devices where continuous performance or performance-on-demand is critical, and failure cannot be tolerated (e.g., life-support, military, aerospace). Class 3 has stricter criteria for solder joint quality, cleanliness, and documentation.

Q2: How do you manage component obsolescence, especially for products with long lifecycles?

A: We employ a proactive strategy: 1) BOM Monitoring with lifecycle status alerts, 2) Last-Time-Buy (LTB) facilitation, 3) Design for Replacement (DFR) to identify and qualify alternates before a crisis, and 4) Component re-balling/re-tinning for critical obsolete ICs.

Q3: What is your approach for sustaining very low Defects Per Million (DPMO) rates in high-volume production?

A: It’s built on a “Quality at the Source” philosophy: in-process verification (SPI, AOI) stops defects from moving to the next station, Statistical Process Control (SPC) charts monitor key parameters, and root cause analysis is mandatory for any escape. We typically target and achieve DPMO rates below 100 for volume runs.

Q4: Can you support both low-volume, high-complexity prototypes and high-volume, cost-sensitive consumer product lines simultaneously?

A: Yes, this is a key strength of our factory layout. We maintain separate, optimized cells for each need. Our NPI Cell is equipped for quick changeovers and handling exotic components. Our Volume Manufacturing Cells are streamlined for maximum throughput of validated designs. The same quality management system governs both, ensuring consistency as projects transition.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..