Date: 2025-12-16

As you embark on an electronics project, the terms “PCB” and “PCBA” appear frequently. While they sound similar and are often used interchangeably, they represent two distinct, sequential stages in the manufacturing process. For manufacturers aiming to efficiently manage their supply chain and product development, a clear understanding of the difference is crucial.

As a professional PCBA manufacturer, Kaboer understands the importance of this distinction in communication and project management. Let's break it down for you.

PCB, or Printed Circuit Board, is the physical foundation and structural core of an electronic product. Think of it as the city's groundwork, road plan, and building lots.

What it is: A substrate made of insulating material (like FR-4 fiberglass) with a精密 network of copper traces etched onto it and holes drilled for component placement. Its familiar green (or other color) appearance comes from the protective “solder mask” coating.

What it does:

Mechanical Support: Provides a solid platform to mount all electronic components.

Electrical Connectivity: Offers预定的, reliable electrical pathways between components through its copper traces, allowing current and signals to flow.

Foundation for Signal Integrity: Good PCB design is fundamental for ensuring high-speed signal quality, minimizing interference, and managing heat.

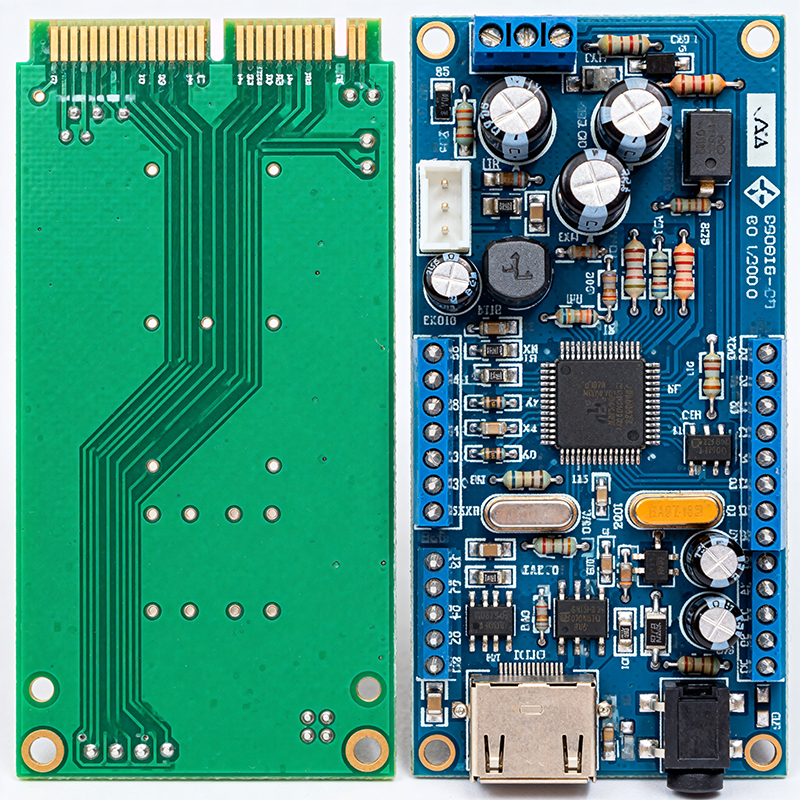

In simple terms, a PCB is a “bare board.” It has all the connection potential but possesses no electronic function by itself. It's like a city plan with only roads and foundations, but no buildings, vehicles, or residents.

PCBA, or Printed Circuit Board Assembly, is the next stage and where functionality is realized. Continuing the analogy, the PCBA is the fully built, lit-up, and operational city.

What it is: PCBA = PCB + All Electronic Components + Assembly Process. It refers to the complete functional module created by accurately placing and soldering all necessary components (resistors, capacitors, chips, connectors, etc.) onto their designated locations on the PCB using精密 processes like SMT and through-hole technology.

What it does:

Enables Electronic Function: Transforms design concepts into具体, working electronic circuits. Only at the PCBA stage can the board be powered on to perform its intended tasks (e.g., processing data, controlling motors, transmitting signals).

Forms the Product Core: The PCBA is often the “mainboard” or “core module” of an electronic device, the physical embodiment of its intelligence and functionality.

Embodies Quality & Reliability: The quality of the assembly process directly determines the final product's performance and long-term reliability.

| Aspect | PCB (Printed Circuit Board) | PCBA (Printed Circuit Board Assembly) |

|---|---|---|

| Nature | Structural item, a blank interconnection substrate. | Functional item, an assembled electronic component. |

| Physical State | Bare board, typically just substrate, copper, and solder mask. | Board populated with soldered components, visually rich. |

| Functional State | Passive, possesses no electronic function. | Active, can perform designed functions when powered. |

| Manufacturing Flow | Involves fabrication processes: imaging, etching, drilling, lamination. | Involves assembly processes: paste printing, component placement, reflow soldering, testing. |

| Supply Chain Stage | Upstream raw material in electronics manufacturing. | Mid-stream core component, ready for final product integration. |

| Industry Terms | Often called “bare board,” “unpopulated board.” | Often called “board,” “module,” “mainboard.” |

Precise Communication: Using the correct term with suppliers (e.g., board houses vs. assemblers) prevents misunderstandings and ensures you get the right quote and deliverable. Requesting a “PCB” should get you bare boards; requesting a “PCBA” should get you assembled, tested modules.

Project Management: It helps you clearly delineate project phases. PCB design and fabrication is one stage, while PCBA assembly and testing is the subsequent, distinct stage, often handled by different specialists.

Cost & Accountability Clarity: Their cost structures and supply chain focuses differ. PCB cost lies in materials and fabrication complexity; PCBA cost adds component sourcing, assembly, and testing. Clear distinction aids in cost analysis and vendor management.

In Shenzhen, China, Kaboer specializes in the PCBA stage. We take your designed PCB files and component list, and leverage our own modern factory and成熟 supply chain to complete the entire process—from component procurement and precision SMT placement to comprehensive functional testing—delivering a reliable, ready-to-use PCBA to you.

We understand that between a quality PCB and a high-performance PCBA lies expert craftsmanship and rigorous quality control. This is precisely our expertise: accurately transforming your design blueprint into the intelligent heart that powers your product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..