Date: 2025-12-16

In the fast-paced world of electronics development, the leap from a validated design to a successful product can feel daunting. Committing to massive production runs too early carries significant financial risk. This is where Low Volume Circuit Board Assembly becomes not just a service, but a critical strategic partner for innovators, startups, and established companies alike.

For manufacturers outside of China looking to develop, test, and launch products efficiently, mastering the "low volume" phase is the key to de-risking innovation and accelerating time-to-market.

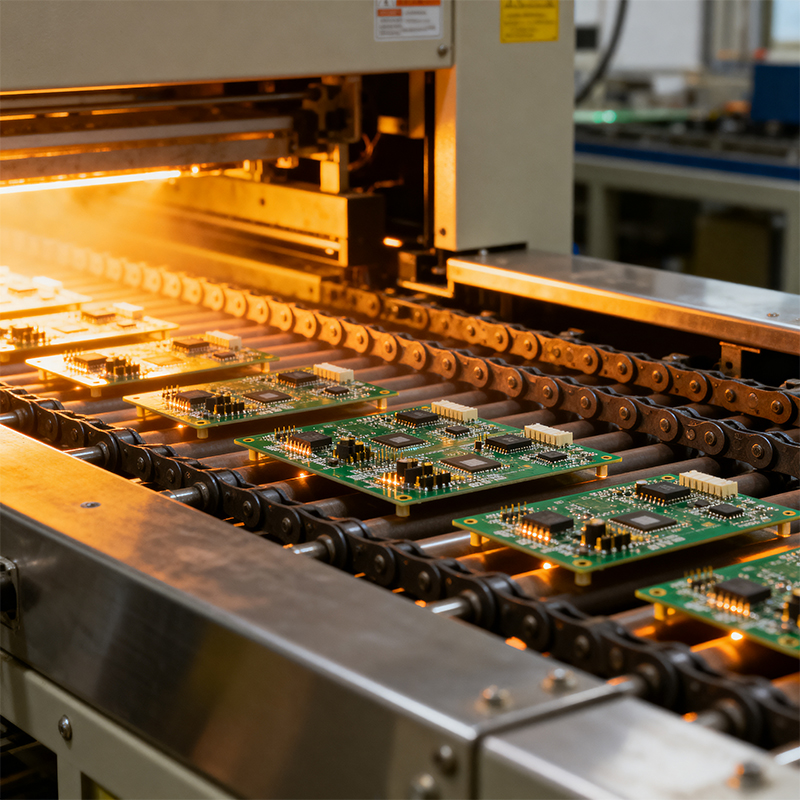

Low Volume Circuit Board Assembly refers to the professional manufacturing and assembly of printed circuit boards (PCBs) in smaller quantities, typically ranging from as few as 5 to 10 prototype units up to several hundred or a few thousand pieces.

It’s a specialized service model designed to bridge the gap between one-off engineering prototypes and full-scale mass production. Unlike high-volume lines optimized for a single, repetitive task, low-volume assembly focuses on flexibility, rapid turnaround, and meticulous attention to detail across a variety of designs.

Why is this phase so crucial? It serves multiple, interconnected strategic purposes:

1. De-risking Your Investment & Validating Design

Before investing tens or hundreds of thousands of dollars in mass production, you need real-world proof. Low-volume runs allow you to:

Build and test fully functional units that are identical to your final product in quality.

Conduct rigorous Design for Manufacturability (DFM) validation in a real production environment, catching issues that simulation might miss.

Perform certifications, field trials, and beta testing with actual users to gather feedback and prove reliability.

2. Accelerating Market Entry and Iteration

Speed is a competitive advantage. Low-volume assembly services offer significantly faster lead times than mass production tooling and setup.

Go-to-Market Faster: Launch a minimum viable product (MVP) to capture early adopters and generate initial revenue.

Iterate Rapidly: Implement design changes, component swaps, or firmware updates based on real feedback and build an improved version without being stuck with obsolete inventory.

3. Enabling Flexible Market Testing

Instead of guessing market demand, you can test it.

Gauge True Demand: Produce enough units for a targeted launch in a specific region or channel.

Manage Cash Flow: Avoid tying up capital in large inventory before sales are confirmed.

Support Niche or Custom Products: Perfect for producing limited runs of specialized industrial, medical, or aerospace products where volumes are inherently low.

4. Securing Your Supply Chain

A low-volume run is the perfect opportunity to:

Audit and qualify your manufacturing partner before scaling up.

Validate component supply and build relationships with distributors.

Lock in processes and documentation that will ensure consistency when you ramp to high volume.

Startups & Entrepreneurs: Validating a first product with limited capital.

R&D Departments: Developing next-generation technology or proof-of-concept systems.

Established Companies: Launching a new product line or updating an existing one.

All Industries requiring pre-production validation: Medical Devices, Aerospace, Automotive, Industrial IoT, Telecom.

Low-volume assembly comes with its own set of challenges that generic manufacturers may struggle with:

High Setup Cost per Unit: Without optimization, NRE (Non-Recurring Engineering) costs can dominate.

Component Sourcing for Small Quantities: Distributors often have high minimum order quantities (MOQs).

Requirement for High-Mix Flexibility: Production lines must handle frequent changeovers efficiently.

Need for Intensive Communication & Collaboration: Every project is unique and requires close partnership.

At Kaboer, based in the global electronics hub of Shenzhen, we understand that the low-volume phase is where great products are proven. Our factory and business model are built to support this critical stage with agility and precision.

We specialize in turning your validated design into a batch of high-quality, fully assembled boards—ready for your testing, certification, or market launch. We provide the dedicated engineering support, flexible sourcing solutions for small quantities, and a transparent process you need to move forward with confidence. Our goal is to be the reliable, responsive partner that helps you bridge the gap from a great idea to a successful product, one efficient low-volume run at a time.

For manufacturers looking to navigate the path from prototype to production with minimized risk and maximized agility, a focused low-volume assembly strategy is indispensable.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..