Three months ago, my team was testing a 5G router prototype built with a rigid-flex PCB. We’d spent weeks tuning the antenna and optimizing the chip, but when we ran speed tests, the results were disastrous: instead of the promised 1.2 Gbps, the router only hit 500 Mbps. Worse, the signal dropped every time we moved the router’s flexible antenna arm.

We brought in our signal specialist, Dr. Eliza, who hooked the PCB up to a network analyzer. The screen told the story: the impedance of the rigid-flex transition zone was all over the place—jumping from 50Ω (our target) to 75Ω, then dropping to 30Ω. “Impedance mismatch is killing your signal,” she said, pointing to the erratic graph. “High-frequency signals (like 5G’s 28 GHz) can’t handle even small impedance shifts—they reflect back instead of passing through.”

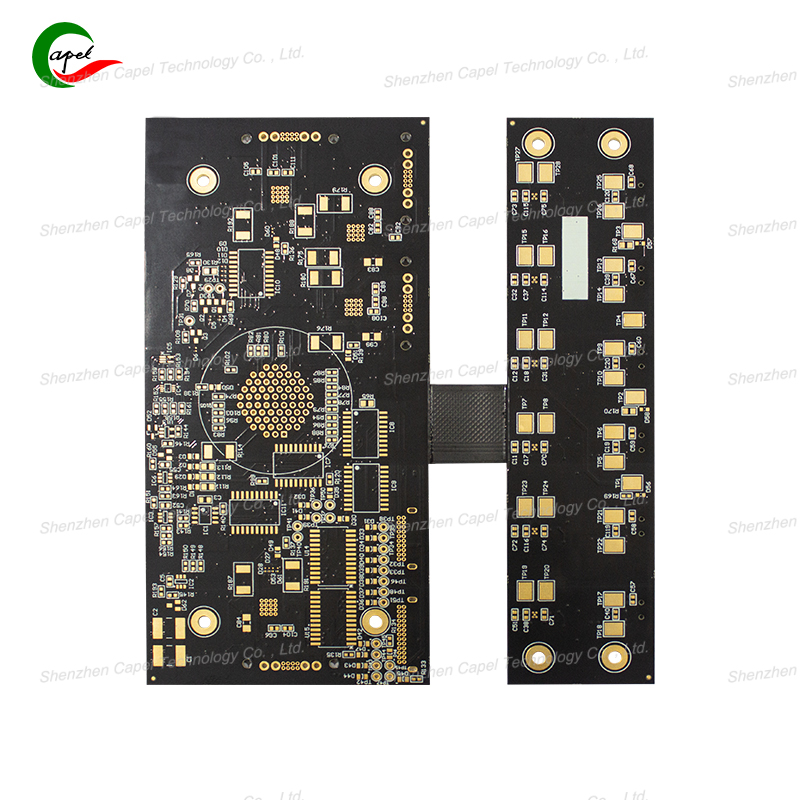

That moment was a wake-up call. For high-frequency devices (5G gear, millimeter-wave sensors, IoT hubs), rigid-flex PCB impedance isn’t just a “technical detail”—it’s the difference between a product that works and one that fails. Traditional rigid PCBs have consistent impedance, but rigid-flex’s mix of FR4 (rigid) and PI (flexible) materials makes impedance control far trickier.

First, let’s keep it simple: impedance is a measure of how much a PCB resists the flow of electrical signals. For high-frequency signals (1 GHz+), two rules apply:

- Impedance must be consistent: If impedance changes along the signal path (e.g., from 50Ω to 75Ω), part of the signal reflects back to the source instead of reaching its destination. This causes signal loss, delays, or dropouts.

- Impedance must match components: Antennas, chips, and connectors are designed for a specific impedance (usually 50Ω for RF signals). A mismatch here is like plugging a 110V device into a 220V outlet—signals get “fried” or lost.

Our 5G router failed both rules. The rigid-flex transition zone’s erratic impedance caused 40% of the 5G signal to reflect back, cutting speed in half. “At 28 GHz, even a 5Ω shift can cause 10% signal loss,” Dr. Eliza said. “Your transition zone was shifting by 45Ω—disaster.”

Rigid PCBs use a single material (FR4) with consistent properties, so impedance is easy to keep steady. Rigid-flex PCBs mix FR4 (rigid sections) and PI (flexible sections)—and these materials have very different electrical properties, which wreak havoc on impedance:

Dielectric constant (εr) measures how a material slows down electrical signals. FR4 has a dielectric constant of ~4.4, while PI film is ~3.5. When a signal moves from FR4 to PI (at the rigid-flex transition), the change in εr causes impedance to jump.

“In your router, the signal went from FR4 (εr=4.4) to PI (εr=3.5) at the transition,” Dr. Eliza explained. “That alone pushed impedance from 50Ω to 65Ω—before we even account for other issues.”

Rigid FR4 sections are thick (1.6mm typical), while flexible PI sections are thin (0.1mm typical). This thickness difference changes the distance between the signal trace and the ground plane—another key factor in impedance. A thinner material means a smaller distance, which lowers impedance.

“Your PI section was half the thickness of the FR4 section,” Dr. Eliza said. “That dropped impedance from 65Ω to 30Ω—creating a huge mismatch.”

During manufacturing, flexible sections are often etched with slightly narrower traces than rigid sections (to fit the thin PI film). Narrower traces increase impedance—adding another layer of mismatch.

“We measured your traces: 0.2mm wide on FR4, 0.15mm on PI,” Dr. Eliza said. “That 0.05mm difference added 10Ω to the impedance—making the total shift 45Ω.”

Fixing our router’s impedance issues wasn’t about “perfect” design—it was about balancing the differences between FR4 and PI. Below are the tips that got our impedance stable at 50Ω and restored the router’s 1.2 Gbps speed:

To smooth the εr change between FR4 and PI, add a thin layer of dielectric material (called a “transition layer”) at the rigid-flex boundary. Choose a material with a dielectric constant halfway between FR4 (4.4) and PI (3.5)—like a modified epoxy with εr=3.9.

We added a 0.1mm-thick transition layer between the FR4 and PI sections. This slowed the εr change from “4.4→3.5” to “4.4→3.9→3.5,” cutting the impedance jump from 15Ω to 5Ω.

Impedance at the transition zone stayed within 50Ω ±5Ω—well within the 5G signal’s tolerance.

Compensate for thickness differences between FR4 and PI by adjusting trace widths. Thinner PI sections need wider traces to keep impedance consistent (wider traces lower impedance, offsetting the thickness effect).

- FR4 section: Kept traces at 0.2mm (matches our 50Ω target for 1.6mm FR4).

- PI section: Widened traces to 0.25mm (offsets the thinner 0.1mm PI, keeping impedance at 50Ω).

“Use an impedance calculator tool (like Polar Instruments’ Si9000) to map trace width to material thickness. For PI, you’ll almost always need wider traces than FR4.”

The ground plane (a copper layer under the signal trace) is critical for impedance control. In rigid-flex PCBs, make sure the ground plane’s size and distance from the signal trace are the same in both rigid and flexible sections.

- In FR4: Ground plane was 0.8mm below the signal trace.

- In PI: We thinned the PI layer slightly (to 0.08mm) and kept the ground plane 0.8mm below the trace—matching the FR4 design.

Thickness-related impedance shifts dropped from 35Ω to 3Ω.

Don’t wait until prototypes fail—test impedance at every stage:

- Design Stage: Use simulation tools to predict impedance shifts.

- Prototype Stage: Use a network analyzer to measure impedance at the rigid-flex transition, trace bends, and component connections.

- Production Stage: Sample 5–10 PCBs per batch and test impedance—catch manufacturing errors (like uneven trace etching) early.

We tested 10 prototype PCBs after making our changes. All had impedance within 50Ω ±3Ω—no more wild shifts. Mass production batches stayed consistent too.

After implementing these tips, we retested the 5G router:

- Speed: Hit 1.18 Gbps—almost our 1.2 Gbps target.

- Signal Stability: No drops when moving the flexible antenna arm (impedance stayed steady at 50Ω ±4Ω).

- Range: Reached 300 meters (up from 150 meters before)—less signal reflection meant more distance.

A local telecom company tested the router and was impressed: “We’ve seen rigid-flex 5G routers fail because of impedance issues,” their engineer said. “Yours is the first that performs as well as rigid PCB models—without the bulk.”

Our 5G router disaster taught us that rigid-flex PCBs need intentional impedance design—especially for high-frequency signals. The mix of FR4 and PI creates unique challenges, but they’re solvable with transition layers, adjusted trace widths, consistent ground planes, and early testing.

As devices push to higher frequencies (5G, 6G, millimeter-wave), impedance control will only grow more critical. Rigid-flex PCBs offer the flexibility to build smaller, more versatile devices—but only if you get impedance right.

Next time you design a rigid-flex PCB for high-frequency signals, ask: “Have we accounted for FR4-PI differences?” If not, start with an impedance calculator and a transition layer. Your signal quality (and your product’s success) will depend on it.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.