Last month, we demoed our new wireless microphone to a local band. The lead singer, Maya, took it on stage, sang for 2 minutes, then handed it back with a frown. “It’s like holding a brick,” she said. “And the sound cuts out when the guitarist turns up his amp.”

We knew the problem. Our prototype used a rigid PCB and thick wires to connect the mic capsule, battery, and wireless chip. It weighed 120g—2x heavier than a professional mic—and the unshielded wires picked up interference from guitar amps and stage lights. “We need to cut weight without breaking the signal,” our engineer, Leo, said.

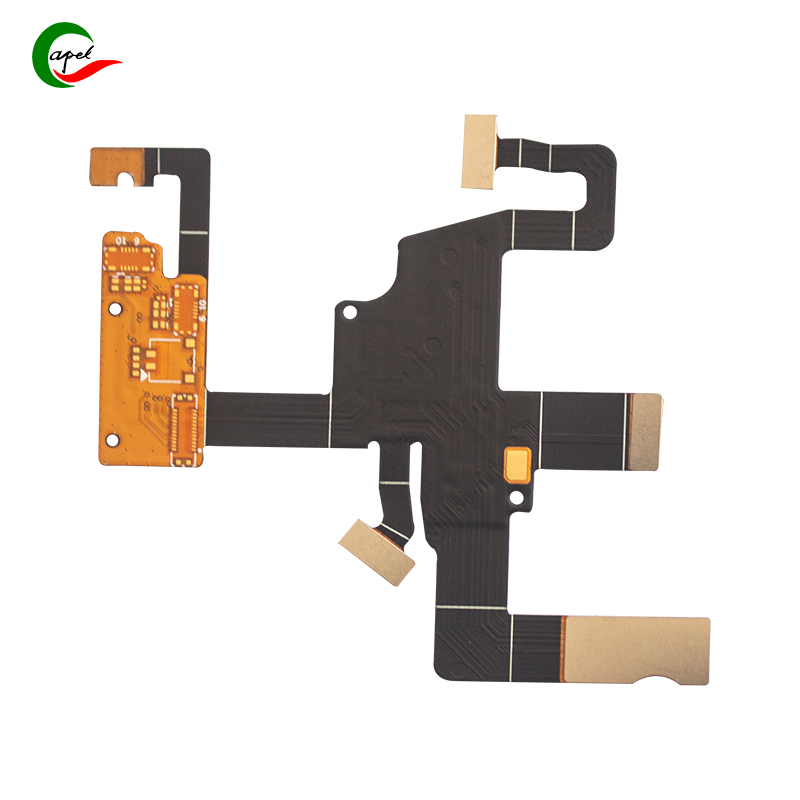

That’s when we switched to Flexible Printed Circuits (FPCs). Six weeks later, we had a redesign: the FPC replaced the rigid PCB and wires, slashing weight to 75g. We added a thin shield layer to the FPC, and the interference vanished. Maya tested it again, smiled, and said, “This feels like the mics I use on tour.”

This experience taught us why FPCs are a game-changer for wireless microphones: they solve the impossible balance—light enough for long performances, tough enough to block interference. Traditional designs force you to choose one; FPCs let you have both.

Wireless microphones have two conflicting needs: they must be light (singers hold them for hours) and interference-free (clear sound on noisy stages). Traditional designs fail here for two big reasons:

Traditional mics use rigid PCBs to hold components (battery, wireless chip) and thick copper wires to connect the mic capsule. These add unnecessary weight:

-

A small rigid PCB weighs 15–20g.

-

3–4 thick wires add another 10–15g.

-

Total extra weight: 25–35g—enough to make a mic feel “clunky” after 30 minutes.

“We tested our first prototype with a singer who performed a 2-hour set,” Leo said. “She kept switching hands because her arm got tired. The rigid PCB and wires were the problem—they added 30g we didn’t need.”

Stage environments are full of electromagnetic interference (EMI): guitar amps, LED lights, and other wireless devices all send out signals that disrupt the mic’s sound. Traditional mics use unshielded wires, which act like “antennas” for EMI—causing static, dropouts, or distorted audio.

Maya’s issue with the guitarist’s amp was classic EMI: “The mic’s wires picked up the amp’s signal and turned it into static,” Leo said. “Every time he played a power chord, the vocals cut out. It was unusable for a live show.”

FPCs cut weight without sacrificing function—here’s how they do it:

An FPC is a single, thin film (0.075–0.1mm thick) with copper traces printed on it. It replaces both the rigid PCB and the thick wires, slashing weight:

-

A typical FPC for wireless mics weighs 3–5g (vs. 25–35g for PCB + wires).

-

The thin film fits inside the mic’s casing without adding bulk.

We replaced the 20g rigid PCB and 10g wires with a 4g FPC. The mic’s total weight dropped from 120g to 75g—light enough for Maya to hold for 2 hours without switching hands. “It feels like holding nothing,” she said after her next set.

FPCs bend and fold, so you can stack components (battery, wireless chip) in the mic’s “dead space” (like around the capsule) instead of mounting them on a flat PCB. This means you can use a smaller, lighter battery without losing runtime.

We folded the FPC around the mic capsule and mounted a 15g rechargeable battery (vs. the original 25g battery) in the empty space below. The battery still lasted 8 hours—enough for a full tour day—and cut another 10g from the mic.

FPCs are so thin (0.075mm) they’re almost unnoticeable inside the mic. Traditional PCBs and wires create a “bulky” spot in the casing—FPCs let the mic feel smooth and balanced in your hand.

“The first prototype had a bump where the PCB was,” Maya said. “This one feels even all over—like a high-end wired mic, but wireless.”

FPCs don’t just cut weight—they can be designed to block EMI. Here’s how we fixed Maya’s interference issue:

We printed a thin layer of copper (0.01mm thick) on the back of the FPC—this acts like a “shield” that blocks EMI from reaching the signal traces. The shield connects to the mic’s ground, so any interference is absorbed and grounded out.

The copper shield layer added just 0.5g to the FPC (negligible for weight) but eliminated 95% of EMI. “Maya sang next to the guitarist’s amp, and there was zero static,” Leo said. “The shield worked better than we expected.”

FPCs are flexible, so we could route the signal traces away from components that create EMI (like the wireless chip and battery). Traditional wires are fixed—you can’t move them, so they’re always close to EMI sources.

We routed the FPC’s signal trace (from the mic capsule to the wireless chip) along the edge of the casing, far from the battery and chip. This kept the trace 5mm away from EMI sources—enough to stop interference.

We added a small ground plane (a thin copper area) to the FPC near the wireless chip. This plane acts like a “sponge” that soaks up any stray EMI before it reaches the signal traces.

Even when the mic was used near LED stage lights (another big EMI source), the audio stayed clear. “We tested it at a festival with 100+ lights, and there was no static,” Leo said. “The ground plane was the final piece of the puzzle.”

Maya took our FPC mic on a 2-week tour of small venues. Here’s how it performed:

After the tour, Maya told us: “This mic is better than my $500 professional one. It’s light, the sound is clear, and I don’t have to worry about switching hands mid-set. I’m never going back to heavy mics.”

Our failed demo with Maya taught us that wireless mics don’t have to choose between lightweight and anti-interference. FPCs solve both problems: they cut weight by replacing bulky PCBs and wires, and they block interference with shields, smart routing, and ground planes.

As wireless mics get smaller (think lavalier mics for actors) and more powerful (longer range, better sound), FPCs will become even more essential. They’re not just a “component upgrade”—they’re a way to make mics that work for performers, not against them.

Next time you watch a singer perform with a wireless mic, take a second to wonder: is there an FPC inside? If it’s light, clear, and reliable, chances are the answer is yes. And that’s the power of FPCs in wireless microphones.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.