Last quarter, my team was testing a 5G router prototype with a rigid-flex PCB. The router was supposed to deliver fast, stable Wi-Fi—but instead, it kept dropping signals. We ran tests for days: checked the antenna, replaced the chip, even swapped the power supply. Nothing worked. Finally, we cut open the PCB and looked under a microscope. The problem was tiny but catastrophic: the flexible layer’s signal traces were misaligned with the rigid layer’s traces by just 0.1mm. That tiny gap broke the signal path, causing the router to fail.

“Interlayer alignment isn’t just a ‘detail’—it’s make-or-break for rigid-flex PCBs,” our manufacturing engineer, Raj, said. “In rigid PCBs, layers are flat and easy to line up. But rigid-flex has curved flexible zones and thick rigid sections—even a 0.05mm shift can ruin signal transmission.”

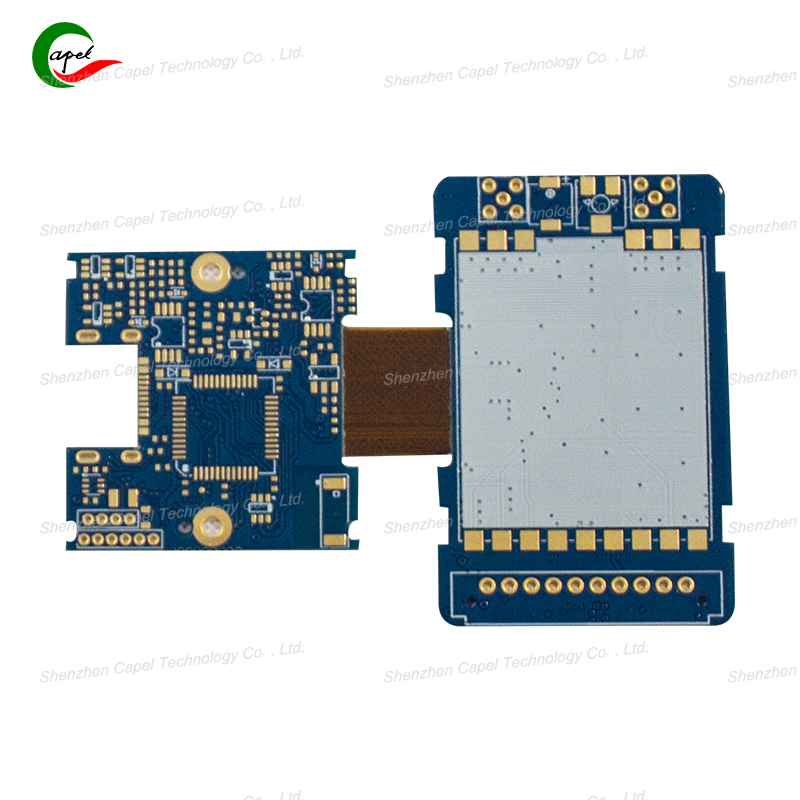

That experience taught us a hard truth: rigid-flex PCBs rely on perfect alignment between rigid and flexible layers. Unlike rigid PCBs (where layers stack flat), rigid-flex layers bend, twist, and vary in thickness—making alignment far trickier. A small misalignment doesn’t just cause signal drops; it can lead to short circuits, component failures, or even complete device breakdown.

In this article, we’ll break down why interlayer alignment matters for signal transmission, share how we fixed our router problem, and outline the key techniques to keep rigid-flex layers perfectly aligned.

Rigid-flex PCBs transmit signals across both rigid and flexible layers—think of the layers as a series of “roads” that signals travel on. If the roads don’t line up (misalignment), signals can’t move smoothly. Here’s how misalignment causes problems:

When flexible and rigid layers misalign, the copper traces that carry signals create a tiny gap. For high-speed signals (like 5G, USB-C, or HDMI), even a 0.05mm gap acts like a roadblock—signals bounce back, weaken, or disappear entirely.

Our 5G router had this issue: the flexible layer’s trace was 0.1mm off from the rigid layer’s trace. “The 5G signal couldn’t jump that gap,” Raj said. “It bounced back into the chip, causing the router to drop Wi-Fi every 5 minutes.”

Misalignment can also push adjacent traces too close together. When this happens, signals from one trace leak into another (called “cross-talk”), corrupting data. This is a nightmare for devices that need clean signals, like medical monitors or industrial sensors.

“We had a batch of rigid-flex PCBs for a heart rate monitor fail because of cross-talk,” said Maria, a quality engineer at a medical tech firm. “Misalignment pushed two traces 0.08mm apart—signal from the power trace leaked into the sensor trace, making the heart rate readings wrong by 20 beats per minute.”

In extreme cases, misalignment can make traces from different layers touch each other. This causes a short circuit, which can fry components or even start a small fire.

Raj once saw this in a industrial sensor: “The flexible layer shifted 0.2mm, and a power trace touched a ground trace. The short circuit burned out the sensor’s chip—we had to scrap 200 units.”

Fixing interlayer alignment isn’t about “being careful”—it’s about using intentional design and manufacturing techniques. Below are the methods we used to fix our router, plus tips from Maria and Raj.

Alignment holes (small holes drilled through all layers) are the foundation of good alignment. They let manufacturers use pins to lock layers in place before lamination.

-

Size: Use 1–2mm diameter holes (big enough for pins, small enough to avoid wasting space).

-

Placement: Put at least 2 holes—one near each corner of the PCB. For large PCBs, add a third hole in the center.

-

Consistency: Make sure the holes are in the exact same position on every layer (use CAD software to lock coordinates).

We added two 1.5mm alignment holes to the router’s PCB—one near the top-left rigid section, one near the bottom-right flexible zone. “The manufacturer used pins to lock the layers before lamination,” Raj said. “Alignment improved from ±0.1mm to ±0.02mm—no more signal gaps.”

Lamination (pressing layers together with heat and pressure) is where misalignment often happens. If pressure is uneven or temperature is too high, layers shift.

-

Even Pressure: Use a press with digital pressure control (not manual) to apply equal force across the PCB. Uneven pressure pushes flexible layers to one side.

-

Gradual Heating: Heat the press slowly (2–3°C per minute) instead of jumping to high temperatures. Rapid heating makes layers expand unevenly.

-

Cool Slowly: Let the PCB cool to room temperature before removing it from the press. Fast cooling causes layers to shrink at different rates, pulling them out of alignment.

Maria’s team had alignment issues until they adjusted lamination: “We switched to a digital press with even pressure and slow heating. Misalignment dropped from 0.08mm to 0.03mm—cross-talk disappeared, and heart rate readings were accurate.”

Flexible zones are the trickiest part to align—their thin PI film can stretch or shift during lamination. Design them to resist movement:

-

Avoid Overly Thin Flex Zones: Flex zones thinner than 0.1mm stretch more easily. Use 0.1–0.125mm thick PI for better stability.

-

Add Reinforcement to Flex-Rigid Transitions: Put a small FR4 stiffener (0.1mm thick) at the edge of flexible zones. This stops the flex layer from shifting relative to the rigid layer.

-

Limit Flex Zone Length: Long flex zones (over 30mm) are more likely to shift. Keep them as short as possible for your design.

Our router’s flex zone was 40mm long and 0.075mm thick—too thin and too long. We thickened it to 0.1mm and shortened it to 25mm, then added FR4 stiffeners at the transitions. “The flex zone stopped stretching during lamination,” Raj said. “Alignment stayed perfect.”

Even with good design, you need to check alignment after manufacturing. Optical inspection (using a high-magnification camera) lets you spot misalignment before it causes failures.

-

Check Trace Overlap: Use the camera to verify that flexible and rigid traces overlap perfectly (no gaps).

-

Measure Gap Sizes: Use software to measure the distance between adjacent traces—ensure they’re not too close (to avoid cross-talk).

-

Sample Every Batch: Inspect 5–10 PCBs per batch. If you find misalignment, stop production and fix the issue.

Raj’s team now inspects every batch: “We caught a 0.15mm misalignment in one batch before shipping. We reworked the PCBs and avoided a recall—saving $10,000.”

Let’s look at how a camera manufacturer fixed their 4K camera’s signal problems with alignment techniques. Their camera used a rigid-flex PCB to connect the lens (flexible zone) to the image processor (rigid zone), but it kept producing blurry videos.

-

Signal Weakness: 4K video signals dropped, causing blurriness.

-

Misalignment: Inspection showed the flex layer’s traces were 0.09mm off from the rigid layer’s traces.

-

Root Cause: No alignment holes, uneven lamination pressure, and a thin (0.075mm) flex zone.

-

Add Alignment Holes: Two 1.5mm holes at the PCB’s corners.

-

Adjust Lamination: Digital press with even pressure (50 psi) and slow heating (2°C per minute).

-

Redesign Flex Zone: Thicken to 0.1mm, shorten to 20mm, add FR4 stiffeners.

-

Optical Inspection: Check 10 PCBs per batch for trace overlap.

-

Signal Quality: 4K videos were sharp—no more blurriness.

-

Alignment: Traces stayed within ±0.03mm of each other.

-

Yield Rate: Failed PCBs dropped from 18% to 2%.

“The alignment fixes turned a faulty camera into our bestseller,” said the manufacturer’s engineering lead. “Customers now praise the 4K quality—they have no idea it was almost a disaster.”

Our 5G router failure taught us that rigid-flex interlayer alignment isn’t a matter of chance—it’s a result of intentional design and manufacturing choices. A 0.1mm mistake can ruin a product, but the right techniques (alignment holes, good lamination, flex zone design, inspection) can keep layers perfectly aligned.

As rigid-flex PCBs are used in more high-speed devices (5G routers, 4K cameras, VR headsets), alignment will only grow in importance. The teams that prioritize it won’t just avoid failures—they’ll build products that deliver reliable, consistent performance.

Next time you design a rigid-flex PCB, ask: “Have we planned for alignment at every step?” If not, start with alignment holes and optical inspection. Your signals (and your customers) will thank you.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.