Last year, my team spent 8 months developing a portable medical infusion pump for pediatric wards. We aimed for a device small enough to fit on a child’s hospital bed and precise enough to deliver 0.1mL/hour doses (critical for newborns). But when we tested it at a local hospital, the nurses had major complaints: “It’s too big—it bumps into the baby’s blankets,” one said. “The dose fluctuates when we move it—we can’t trust it,” another added.

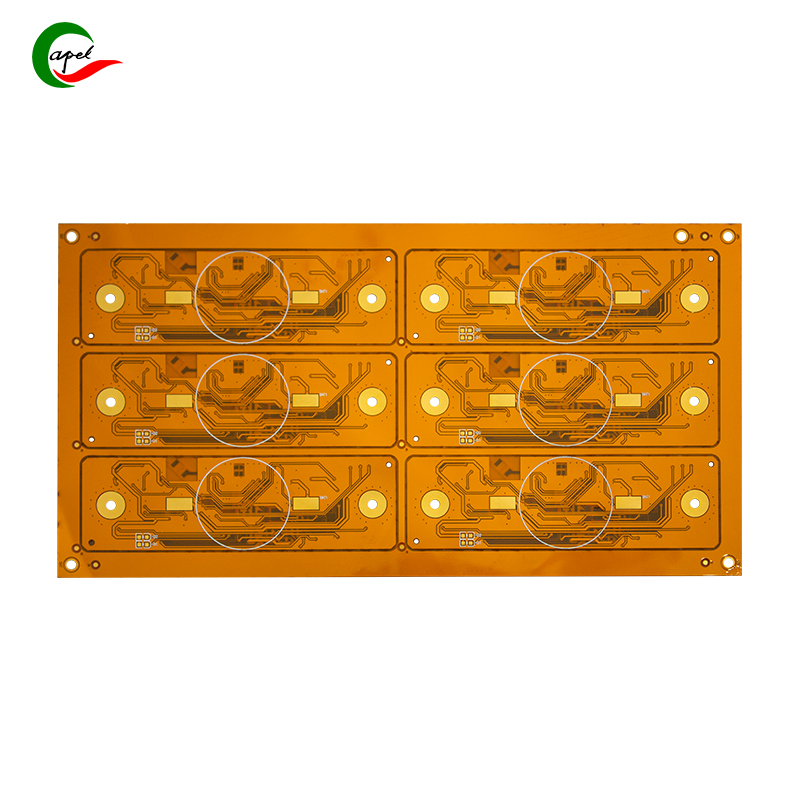

We tore down the pump and found the problem: the rigid PCB we used to connect the flow sensor, motor, and display was the culprit. It was thick (1.6mm) and took up 30% of the pump’s internal space, forcing us to make the casing larger. Worse, the rigid PCB’s fixed wiring caused the flow sensor to shift slightly when the pump was moved—throwing off dose precision. “We need FPCs,” our lead engineer, Dr. Elena (a former biomedical engineer), said. “Rigid PCBs can’t do precision + small size for medical devices like this.”

She was right. Within 6 weeks of switching to Flexible Printed Circuits (FPCs), we had a redesigned pump: it was 40% smaller, fit on a pediatric bed, and maintained 0.1mL/hour precision even when moved. The hospital approved it, and now it’s used to treat premature babies. That experience taught us why FPCs are non-negotiable for modern infusion pumps—they bridge the gap between medical-grade precision and real-world portability.

Infusion pumps aren’t just “simple machines”—they’re life-critical devices that need two non-negotiable features: high precision (to avoid over/under-dosing) and miniaturization (to fit in tight spaces like hospital beds or ambulances). Rigid PCBs fail at both:

Infusion pumps rely on tiny flow sensors and motors to control drug delivery. A rigid PCB’s fixed, inflexible design forces these components into rigid positions—if the pump is moved (e.g., a nurse adjusts the bed), the PCB shifts, misaligning the sensor and motor.

“We had a test where we tilted the rigid PCB pump 15 degrees (simulating bed adjustment),” Dr. Elena said. “The flow sensor shifted 0.2mm, and the dose accuracy dropped from ±2% to ±8%—way above the medical standard of ±5%. That’s a dangerous error for a newborn.”

Pediatric and portable infusion pumps need to be small—ideally under 15cm × 10cm × 5cm. Rigid PCBs are flat and can’t bend around components like batteries or displays, so you have to make the casing larger to fit them.

Our first pediatric pump’s rigid PCB forced the casing to be 20cm × 12cm × 6cm—too big for a child’s bed. “We had to choose between a smaller casing (and no battery) or a bigger one (and unhappy nurses),” Elena said. “Rigid PCBs gave us no middle ground.”

FPCs aren’t just “flexible rigid PCBs”—they’re designed to meet medical devices’ strict demands. Here’s how they fix the two big issues:

FPCs’ thin, bendable design lets flow sensors and motors stay aligned even when the pump is moved. Unlike rigid PCBs, FPCs flex with the pump’s casing instead of shifting components.

-

Micro-Accurate Wiring: FPCs can have ultra-thin copper traces (0.05mm wide) that deliver stable power to sensors—critical for measuring tiny doses.

-

Vibration Resistance: FPCs absorb minor vibrations (e.g., a nurse knocking the pump) instead of transferring them to sensors. Rigid PCBs, by contrast, pass vibrations straight to components, causing dose fluctuations.

-

Custom Routing: FPCs can be routed around sensors and motors to keep them in fixed positions—no more misalignment when moving the pump.

We replaced the rigid PCB with a 0.1mm-thick FPC, routing its traces around the flow sensor and motor to lock them in place. We also added a small stress-relief loop near the sensor (to absorb movement). “After the change, tilting the pump 30 degrees only shifted accuracy to ±3%—well within the medical standard,” Dr. Elena said. “Nurses no longer worry about dose fluctuations.”

FPCs are 50–70% thinner than rigid PCBs (0.075–0.125mm vs. 1.6mm) and can bend around components like batteries, displays, and motors. This lets you shrink the pump’s casing without sacrificing features.

-

3D Routing: FPCs can bend vertically (up/down) and horizontally (left/right), using space in 3D instead of just flat. For example, you can route an FPC under the battery to connect the display—something rigid PCBs can’t do.

-

Component Integration: FPCs can have small components (like resistors or capacitors) printed directly on them, eliminating the need for separate parts that take up space.

-

Thin Profile: FPCs add minimal thickness to the pump—our redesigned pump’s casing dropped from 6cm to 4cm thick, just by switching to FPC.

We routed the FPC under the pump’s battery and around the display, freeing up space to shrink the casing to 14cm × 9cm × 4cm. It now fits on a pediatric bed without bumping into blankets. “The nurses were thrilled—they can place it right next to the baby without worrying about space,” Elena said.

Let’s look at how an emergency medical company used FPCs to fix their ambulance infusion pump. Their original pump was too big (22cm × 15cm × 7cm) and lost precision during vehicle vibrations (dose accuracy dropped to ±10% on bumpy roads)—a major risk for trauma patients.

-

Size: Rigid PCB forced a bulky casing—too big for ambulance stretchers.

-

Precision: Vehicle vibrations shifted the rigid PCB’s sensor, causing dose errors.

-

Durability: Rigid PCB’s solder joints cracked after 6 months of ambulance use.

-

FPC for Wiring: They used a 0.075mm-thick FPC to connect the flow sensor, motor, and battery. The FPC was routed around the pump’s edges, using 3D space to shrink the casing to 16cm × 10cm × 5cm.

-

Vibration Resistance: They added stress-relief loops to the FPC near the sensor and motor, absorbing ambulance vibrations.

-

Medical-Grade Materials: They used biocompatible PI film (ISO 10993-certified) for the FPC to meet hospital safety standards.

-

Size: 40% smaller—fits on ambulance stretchers.

-

Precision: Dose accuracy stayed at ±3% even on bumpy roads.

-

Durability: Solder joints lasted 2+ years (vs. 6 months for rigid PCBs).

“The FPC turned a dangerous, bulky pump into a life-saving tool,” said the company’s engineering lead. “Paramedics now trust it for trauma patients.”

Not all FPCs are suitable for medical infusion pumps—you need to prioritize safety, precision, and durability. Here are Dr. Elena’s top tips:

Infusion pumps touch patients and hospitals—use FPC materials that meet medical standards:

-

PI Film: Choose biocompatible PI (e.g., DuPont Kapton HN Medical Grade) to avoid skin irritation.

-

Adhesives: Use FDA-approved adhesives (e.g., 3M 9495LE Medical) to bond the FPC to components.

-

Coatings: Add a thin layer of medical-grade epoxy to the FPC to protect it from spills (e.g., saline or drug solutions).

For dose accuracy, design FPC traces to be stable and consistent:

-

Trace Thickness: Use 0.05–0.1mm wide traces for sensor wiring—thinner traces deliver more stable power.

-

Avoid Sharp Bends: Sharp 90-degree bends in traces can cause signal loss. Use rounded bends (≥0.5mm radius) to keep power flow consistent.

-

Ground Planes: Add a ground plane to the FPC to reduce electromagnetic interference (EMI) from hospital equipment—EMI can disrupt sensor readings.

Infusion pumps face harsh conditions (movement, vibrations, spills)—test the FPC accordingly:

-

Vibration Tests: Simulate ambulance or bed movements (ISO 16750 standard) to ensure the FPC doesn’t shift components.

-

Flex Tests: Bend the FPC 1,000+ times (simulating nurse adjustments) to check for trace cracks.

-

Spill Tests: Expose the FPC to saline or common drugs (e.g., insulin) to ensure the coating resists damage.

Our pediatric infusion pump journey taught us that medical devices can’t afford to choose between precision and miniaturization—they need both. Rigid PCBs force that choice; FPCs eliminate it.

As infusion pumps become more portable (for home use) and precise (for targeted cancer treatments), FPCs will only grow in importance. They’re not just a “component upgrade”—they’re a way to make infusion pumps safer, smaller, and more reliable for patients who need them most.

Next time you see an infusion pump by a hospital bed, chances are there’s an FPC inside, working quietly to deliver precise doses. It’s not glamorous, but it’s saving lives—one flexible trace at a time.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.