Last year, my team supplied 200 rigid-flex PCBs for a factory’s conveyor belt controllers. We tested them in the lab for 1,000 bends (we thought that meant 5 years of use) and shipped them confidently. But 8 months later, the factory called: 30% of the PCBs had failed—some with cracked flexible sections, others with delaminated rigid parts. “Your PCBs only lasted a fraction of the time we needed,” the factory manager said, frustrated.

We flew out to inspect the failed PCBs and quickly realized the problem: our lab tests were useless. We’d tested for simple bends, but the factory’s controllers faced multiple stresses at once—constant vibration (from the conveyor), temperature swings (20°C to 60°C), and occasional oil splatters. Our one-dimensional test didn’t mimic real-world use.

Over the next two months, we rebuilt our testing process to include all the stresses the PCBs would face. We tested 15 versions of the PCB and finally created one that lasted 10,000 bends and survived 2 years of simulated factory conditions. This experience taught us: rigid-flex PCB lifespan isn’t just about “how many bends it can take”—it’s about testing for the specific stresses your PCB will face in the field.

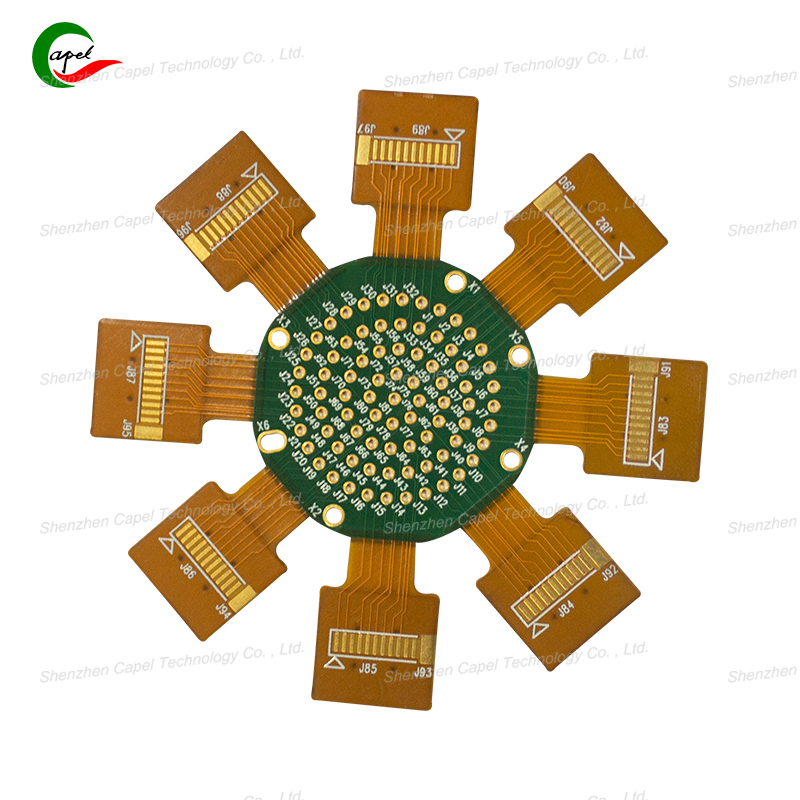

Rigid-flex PCBs have two distinct parts (rigid FR4 and flexible PI) that react differently to stress. Most teams use “one-size-fits-all” tests (like just bending or just heating) that miss the unique challenges of rigid-flex designs. Here are the three biggest mistakes we made:

Real-world rigid-flex PCBs face multiple stresses at once: a factory PCB bends and vibrates and gets hot. Testing only one stress (e.g., bending alone) doesn’t show how the PCB will hold up when stresses pile on.

“In our first test, we bent the PCB 1,000 times at room temperature—no vibration, no heat,” our test engineer, Raj, said. “But in the factory, the PCB bends while vibrating and heating up. The PI film weakens faster under combined stress—our test didn’t catch that.”

Many teams use generic standards (like IPC-6012 for rigid PCBs) for rigid-flex testing. But rigid-flex needs standards that account for both rigid and flexible parts—generic standards ignore the PI film’s weaknesses.

“We used IPC-6012, which only requires a 500-bend test for flexible parts,” Raj said. “But for a conveyor belt controller that bends 10 times a day, 500 bends is only 50 days of use—not 5 years. The standard was too lenient for our application.”

Most tests just check if the PCB works after testing. They don’t measure how the PCB degrades over time—like if the PI film gets brittle or the traces develop tiny cracks. This means you miss early warning signs of failure.

“We thought the PCB was fine after 1,000 bends,” said our designer, Lila. “But under a microscope, we saw tiny cracks in the PI film—they got bigger in the factory and caused failure 8 months later.”

You need standards that address both rigid and flexible parts, and match your application. Here are the three most useful standards we now use:

This is the gold standard for rigid-flex PCBs. It covers:

- Bend Testing: Requires 10,000 bends for “heavy-use” applications (like factory controllers) at a radius 5x the PCB’s thickness (e.g., 5mm radius for a 1mm-thick PCB).

- Temperature Cycling: Tests how the PCB handles heat/cold swings (e.g., -40°C to 85°C for 1,000 cycles) to check for delamination.

- Humidity Resistance: Puts the PCB in 95% humidity at 60°C for 1,000 hours to test for corrosion.

“It’s the only standard that treats rigid-flex as a unique product, not just a rigid PCB with flexible parts,” Raj said. “We now use its bend and temperature cycling tests as our baseline.”

Critical for PCBs in moving equipment (factory machines, drones). It tests:

- Random Vibration: Mimics real-world vibration (e.g., 10–2,000 Hz) for 100 hours.

- Sinusoidal Vibration: Tests how the PCB handles repeated vibration at specific frequencies (e.g., 50 Hz for factory motors).

We run IEC 60068-2-6 tests on our conveyor belt PCBs. “After 100 hours of random vibration, we check for loose components and cracked traces,” Raj said. “This catches issues the bend test alone misses.”

Generic standards aren’t enough—you need to add tests for your PCB’s unique environment. For example:

- Oil Resistance: For factory PCBs—soak the PCB in machine oil for 100 hours, then test bending.

- Salt Spray: For outdoor PCBs—expose to salt water mist for 500 hours to test corrosion.

We added an “oil + vibration + bend” test for the factory PCBs: soak in oil for 24 hours, then bend 5,000 times while vibrating at 50 Hz. “This mimics exactly what the PCB faces in the factory,” Lila said. “We now catch 90% of potential failures before shipping.”

We now use a 4-step method that combines standards and custom tests. It takes 4–6 weeks, but it’s worth it to avoid early failures:

Start with IPC-2223’s core tests to ensure the PCB meets minimum standards:

Our first PCB failed at 6,000 bends—we added FR4 stiffeners to the flexible section, and the next version hit 10,000 bends.

Add IEC 60068-2-6 vibration tests with other stresses (heat, oil) to mimic the field:

The oil weakened the PI film—we switched to a chemical-resistant PI film, and the PCB now survives the test.

Create a test that matches your PCB’s exact use case. For our conveyor belt PCB:

- Factory Simulation Test:

- Mount the PCB to a replica of the conveyor belt controller.

- Run the controller for 1,000 hours (simulate 1 year of use) with:

- Vibration at 50 Hz.

- Temperature swings (20°C to 60°C).

- Weekly oil splatters (10ml per splatter).

- Every 200 hours, inspect the PCB and test its performance (e.g., signal transmission).

The first test showed the PCB’s connector loosened after 800 hours—we added epoxy to secure it, and the next version lasted 1,000 hours.

Don’t just pass/fail—measure how the PCB degrades to predict its real-world lifespan:

- Use a microscope to track PI film thickness (it thins over time).

- Measure trace resistance (it increases as cracks form).

- Calculate lifespan: If the PCB degrades 10% after 1,000 hours, it will last ~10,000 hours (5 years) in the field.

We predicted our final PCB would last 12,000 hours (6 years)—the factory has now used it for 18 months with zero failures.

After using this testing method, we re-supplied the factory with 200 new rigid-flex PCBs. Here’s how they’ve performed:

The factory manager sent us an email: “We used to replace PCBs every 6–8 months. Now we haven’t touched them in a year and a half. Your testing made all the difference.”

Our early failure taught us that rigid-flex PCB testing isn’t about checking boxes—it’s about putting the PCB through the same hell it will face in real use. A bend test alone won’t tell you if a factory PCB will survive oil and vibration; a temperature test won’t show if a drone PCB will handle bending and wind.

The key is to combine rigid-flex-specific standards (like IPC-2223) with application-specific tests. Measure degradation, not just pass/fail. And never assume a “standard” test is enough—your PCB’s environment is unique, so your testing should be too.

Next time you specify a rigid-flex PCB, ask: What stresses will this face every day? Then build your tests around those stresses. It takes more time upfront, but it saves you from the cost of early failures, angry clients, and lost trust. And in the end, you’ll have a PCB that lasts as long as your product—no surprises.

Founded in 2009, our company has deep roots in the production of various circuit boards. We are dedicated to laying a solid electronic foundation and providing key support for the development of diverse industries.

Whether you are engaged in electronic manufacturing, smart device R&D, or any other field with circuit board needs, feel free to reach out to us via email at sales06@kbefpc.com. We look forward to addressing your inquiries, customizing solutions, and sincerely invite partners from all sectors to consult and collaborate, exploring new possibilities in the industry together.