Date: 2026-01-22

Imagine you're designing a device that needs to fold, twist, or fit into a tight, unusual space. Maybe it's a compact camera, a cutting-edge wearable, or a medical probe. The traditional solution? Connect several separate, rigid circuit boards with clunky wires, connectors, and cables. It's bulky, prone to failure, and a nightmare to assemble.

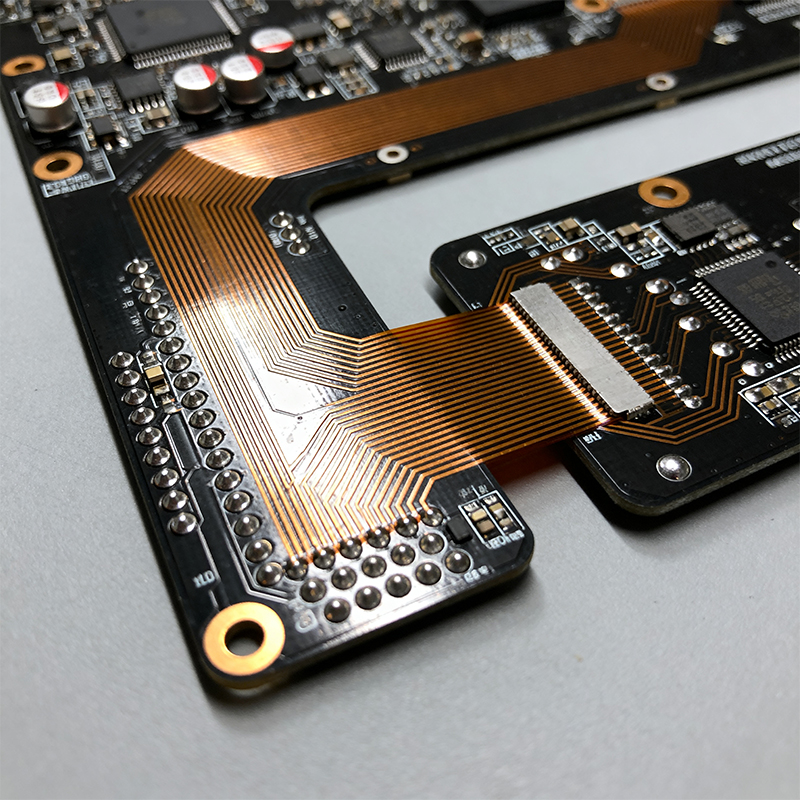

There's a better way. It's called the Rigid Flex PCB. Think of it not as a single board, but as a hybrid puzzle piece that's part solid, part flexible, all made as one continuous, integrated unit. It’s like a sheet of high-tech "paper" that has rigid cardboard sections where you need strength and stability, connected by flexible creases where you need to bend.

Let's break down what makes this technology so special, and why it’s the secret ingredient in so many of today’s sleekest gadgets.

The name says it all. A Rigid Flex PCB is a printed circuit board that combines rigid board sections and flexible circuit sections into a single, unified assembly. They are laminated together in a seamless build-up, with the conductive copper traces running continuously from the rigid areas into the flexible ones.

Here's a simple way to picture it:

Rigid Sections = "The Islands." These are made from standard, sturdy PCB material (like FR4). This is where you mount all your heavy or sensitive components—the processor, memory chips, connectors. They provide a stable, durable platform.

Flexible Sections = "The Bridges." These are made from a thin, bendable polymer film (like polyimide). They act as dynamic, moving connections between the rigid islands, replacing dozens of wires and connectors.

It’s not two different things glued together. It’s one engineered part designed from the start to be both strong and supple where needed.

Designing with Rigid Flex isn't just about being fancy. It solves fundamental engineering problems:

Space and Weight Savings (The Biggest Win): By eliminating connectors, cables, and extra board-to-board interfaces, you can reduce the total volume and weight of your electronics by 30% or more. This is critical for drones, medical implants, and smartphones.

Unmatched Reliability: The single most common point of failure in electronics is the connector. Every plug-and-socket pair is a potential source of corrosion, loosening, or cracking. A rigid flex design is a continuous, solder-free connection. There are fewer interconnects to fail, making the entire system vastly more reliable for products that move, vibrate, or face harsh environments.

3D Design Freedom: You are no longer limited to flat, 2D boards that must be stacked in boxes. A rigid flex assembly can be folded and formed to fit the exact contours of your product's enclosure, like wrapping around a battery or snaking through a hinge. This allows for truly innovative product shapes.

Simplified Assembly: Instead of sourcing, stocking, and assembling multiple rigid boards, cables, and connectors, you have one integrated part to install. This simplifies your bill of materials (BOM) and streamlines the final product assembly line, reducing labor and potential for human error.

Once you know what to look for, you'll find them everywhere advanced packaging is needed:

Consumer Electronics: The folding hinge in a modern flip-style smartphone? Almost certainly a rigid flex. It connects the display to the motherboard while bending tens of thousands of times.

Medical Devices: Small, reliable, and shape-conforming. Used in hearing aids, endoscopic cameras, and wearable monitors.

Automotive & Aerospace: In spaces where vibration resistance and reliability are non-negotiable, like in dashboard displays, sensor arrays, and satellite components.

Industrial & Military: For robust equipment that must endure shock, extreme temperatures, and tight packaging.

Rigid Flex is a powerful tool, but it’s not a universal replacement for standard PCBs.

Higher Initial Cost: The design is more complex, and the manufacturing process is more involved. The upfront engineering and prototyping cost is higher than a simple rigid board.

Design Expertise is Crucial: Designing a rigid flex board is a specialized skill. You need to plan the bend areas carefully (bend radius, dynamic vs. static bends), manage the stack-up of materials, and understand how the board will be folded during final assembly. Poor design can lead to cracked traces in the flex areas.

Prototyping Can Be Slower: Because it's a custom, multi-layer lamination process, getting prototypes can take longer than with standard boards.

This is the most important part. Moving to Rigid Flex isn't just a design change; it's a manufacturing partnership shift. You cannot design it in a vacuum and throw it over the wall to any standard PCB shop.

The manufacturer needs deep, integrated expertise in both rigid PCB fabrication and flex circuit processing. They must understand the unique materials, the precision lamination process, and the specialized handling required.

This is where a company with control over its full process, like Kaboer in Shenzhen, provides a distinct advantage. Our engineers don’t just receive Gerber files; they can collaborate from the early design phase. We can advise on:

Material selection for the right flex-to-rigid transition.

Designing for a reliable bend radius to prevent failure.

Planning for how the assembly will be folded and secured in your product.

Executing the precise SMT assembly on the rigid sections, which often requires special fixtures to support the flexible "tails."

We manage the entire journey—from the complex lamination of the bare board to the careful assembly of components—ensuring the final part is not just a circuit, but a reliable, three-dimensional mechanical component for your product.

Rigid Flex PCB technology is a game-changer for products where space, weight, reliability, and innovative form factors are key competitive advantages. It replaces a tangle of parts with an elegant, integrated solution.

It’s not for every project, but when your design calls for it, choosing the right manufacturing partner is the single most critical decision you’ll make. It requires a team that speaks both the language of advanced circuit design and precision mechanical assembly. When done right, it’s the invisible magic that makes the most impressive modern electronics possible.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..