Rigid PCB Sizes: What’s the Best Fit, and What’s the Manufacturing Limit?

Date: 2025-09-28

If you’re building electronics—whether it’s a DIY project, a small gadget, or a big industrial machine—you might wonder: How big should my rigid PCB be? And is there a point where a PCB gets too big (or too small) to make? Let’s break this down simply, with no confusing jargon—just what you need to know to pick the right size.

There’s no one “perfect” size—because it depends on what you’re using the PCB for. But here are the key things that decide the right size, with real examples:

This is the most basic rule. If you’re making a small Bluetooth speaker, your PCB can’t be bigger than the speaker’s case. For example:

- A phone’s PCB is tiny (usually around 5x8cm) because it has to fit inside the phone’s slim body.

- A desktop computer’s motherboard (a big rigid PCB) is around 30x24cm—because it needs to hold the CPU, RAM, and other large parts, and fit inside the computer case.

If you have a lot of parts (like chips, sensors, or capacitors), you need a bigger PCB to fit them without overlapping. For example:

- A simple LED light’s PCB is small (2x3cm) because it only needs a few components (a resistor, an LED).

- An industrial control panel’s PCB is bigger (15x20cm) because it has to connect multiple sensors, buttons, and display screens.

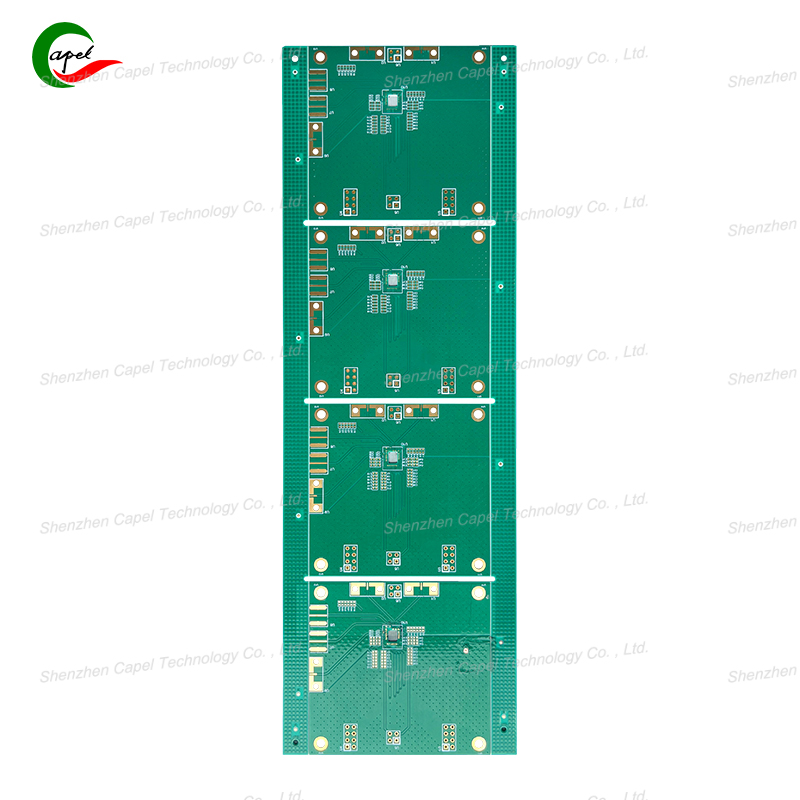

Super small or super big PCBs cost more to make. Most factories work best with PCBs between 5x5cm and 30x40cm—this size range is easy to handle with standard machines, so it’s cheaper for you. For example:

- A PCB smaller than 3x3cm is hard to grip with manufacturing machines (like those that drill holes), so factories charge extra to make it.

- A PCB bigger than 40x50cm needs special machines to print the circuit, which also adds cost.

For most projects, a rigid PCB between 5x5cm and 30x40cm is the sweet spot—it fits most devices, holds enough components, and is affordable to make.

Factories can’t make rigid PCBs infinitely big or small—their machines and materials have limits. Here’s what you need to know:

The practical limit for a rigid PCB is around 1x1cm—but even that is tricky. Here’s why:

- Machines can’t easily place tiny components (like 01005-sized chips, which are smaller than a grain of sand) on a PCB this small without missing.

- Drilling small holes (needed to connect components) is hard—holes smaller than 0.1mm can break the drill bit.

Most projects don’t need PCBs this small. If you need something tiny, you’ll probably use a flexible PCB instead (they’re easier to make in small sizes).

The largest standard rigid PCB most factories can make is around 60x120cm—but this is rare. Here’s why it’s hard to go bigger:

- The substrate (the hard base of the PCB) bends when it’s too big. A PCB bigger than 120cm will start to sag during manufacturing, which messes up the circuit printing.

- Standard machines (like those that apply solder mask) can’t reach across a PCB bigger than 60x120cm—factories need custom-built machines, which are expensive.

For example:

- A big TV’s main PCB is around 40x50cm—this is near the limit of what standard factories can make affordably.

- If you need a PCB bigger than 60x120cm, you’ll have to split it into multiple smaller PCBs and connect them with wires (this is cheaper than making one giant PCB).

It’s not just size—thickness and component density matter too:

- Thickness: Most rigid PCBs are between 0.8mm and 2mm thick. Thinner than 0.8mm, the PCB breaks easily; thicker than 3mm, machines can’t drill holes all the way through.

- Component density: You can’t cram too many parts onto a small PCB. If components are too close, they’ll overheat or short-circuit.

The “best” rigid PCB size isn’t about a number—it’s about what fits your device, holds your parts, and doesn’t cost a fortune. And while factories have limits, they’re flexible enough to handle most projects (from tiny LED PCBs to big motherboards). If you’re unsure, ask your PCB manufacturer—they’ll help you pick a size that works.

related link: