Date: 2026-02-05

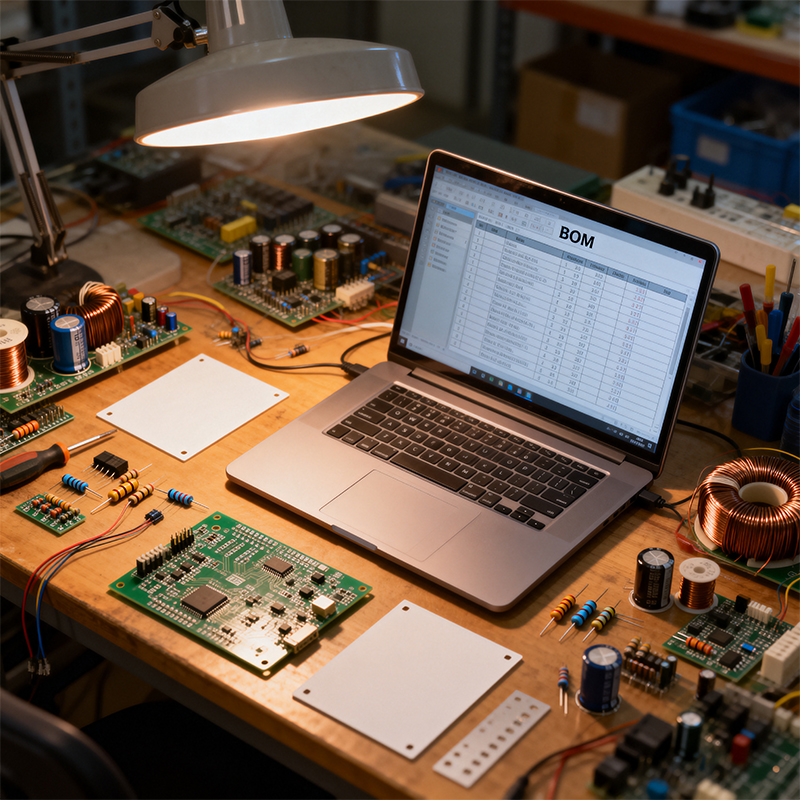

Imagine following a new recipe—it lists all required ingredients, exact amounts, preparation steps, and even recommends specific kitchenware brands. In electronics manufacturing, the Bill of Materials (BOM) is this "recipe," and the sample BOM is the special version you use when trying the dish for the first time.

Simply put, a BOM is a detailed list of all materials, components, and parts needed to build a product. It tells the manufacturing team: "To make this product, we need these specific things, in these quantities, combined in this way." The sample BOM is a version specifically prepared for creating the first prototypes or test samples.

While sample BOMs and production BOMs may look similar, they serve completely different purposes:

Characteristics of Sample BOM:

Flexibility prioritized: Allows alternative components for testing

Small-quantity procurement: Components may come from distributor stock rather than directly from factories

Design-oriented: Focus on function verification rather than cost optimization

Frequent changes: Rapid iteration based on test results

Potentially simplified documentation: Some manufacturing details may not yet be finalized

Characteristics of Production BOM:

Cost-optimized: Value-engineered to select the most cost-effective components

Stable supply chain: Long-term relationships with qualified suppliers ensure steady supply

Manufacturing-optimized: Considers production efficiency, testing processes, and manufacturability

Strict change control: Any modifications require formal engineering change processes

Complete, precise documentation: Includes all manufacturing, testing, and compliance details

Key difference example: In the sample phase, you might use a standard development board module (like an Arduino) to quickly test concepts, while in production, you'd design a custom PCB and use a lower-cost microcontroller chip.

A complete sample BOM is like a detailed product "ID card" and "instruction manual," typically containing:

1. Basic Project Information

Product name and model number

BOM version and date

Creator and review status

Sample purpose description (functional verification, certification testing, etc.)

2. Main Bill of Materials

This is the core table of the BOM, usually including:

Item number: Unique identifier for each component (1, 2, 3...)

Component number/Part number: Manufacturer's or internal unique identifier

Description: Clear explanation of what the component is

Quantity: How many are needed per sample

Reference designator: Location on the circuit diagram (e.g., R1, C5, U3)

Package/Specifications: Physical dimensions and technical specifications

Manufacturer and manufacturer part number: Specific source information

Supplier and supplier part number: Procurement source information

Notes/Alternatives: Important notes or alternative options

3. Additional Information

Special assembly instructions

Testing requirements and procedures

Safety and compliance considerations

Version history record

1. Design Verification Roadmap

The sample BOM is the first physical representation of the design team's ideas. It ensures that all theoretical designs have corresponding actually available components. For example, a "5V voltage regulator" in the design would be specified as "Texas Instruments TPS7A4700RGWR 5V 1A Low Dropout Regulator" in the BOM.

2. Procurement Guide

For the procurement team, the sample BOM is a precise shopping list. It clearly indicates what needs to be purchased, in what quantities, and from which reliable sources. A good sample BOM also provides alternative component options in case the preferred components are unavailable.

3. Cost Estimation Foundation

Through the sample BOM, teams can preliminarily understand the product cost structure. Although component prices in the sample phase may be relatively high (small quantity purchases), this provides a cost baseline, helping to identify expensive components that could be cost-reduced in the future.

4. Manufacturing Preparation

The sample BOM is the production team's first step in preparing manufacturing processes. It helps identify components requiring special handling or tools, such as miniature components needing manual soldering or heat sinks requiring specific installation procedures.

5. Testing and Certification Framework

For products requiring certification (such as FCC, CE), the sample BOM ensures test samples match the final product. Certification bodies typically require the BOM as part of the test documentation.

Step 1: Start with Design Files

Most sample BOMs originate from Electronic Design Automation (EDA) tool outputs. After schematic design is complete, EDA software can generate an initial BOM listing all circuit components. But this is just the starting point—significant manual addition of critical information is needed.

Step 2: Fill in Component Details

For each component in the BOM, supplement with:

Complete manufacturer name and accurate part number

Preferred supplier information

Package and specification details

Any special requirements or considerations

Step 3: Consider Alternatives

During the sample phase, supply chain flexibility is crucial. Identify 2-3 alternative options for critical components and document them in the BOM. This prevents entire sample production from stalling due to a single component shortage.

Step 4: Review and Verification

Invite representatives from design, procurement, and manufacturing teams to jointly review the sample BOM. This cross-checking process can uncover potential issues such as:

Designs using discontinued components

Extremely long lead times for certain components

Compatibility issues between components

Underestimated manufacturing difficulties

Step 5: Version Control and Distribution

The sample BOM is a "living document" that will be frequently updated during testing and iteration. Establishing a clear version control system is crucial:

Update version numbers with each change

Record what changed, why, and when

Ensure all team members use the same version

Pitfall 1: Incomplete Information

Problem: BOM only lists component types, missing specific manufacturer part numbers.

Consequence: Procurement team may order wrong components, delaying sample production.

Solution: Establish a BOM review checklist ensuring each entry has complete information.

Pitfall 2: Ignoring Supply Chain Realities

Problem: Some components in the BOM have lead times as long as 20 weeks.

Consequence: Significant delays in sample production.

Solution: Early involvement of procurement team to provide component availability feedback.

Pitfall 3: Version Confusion

Problem: Team members use different BOM versions.

Consequence: Manufactured samples don't match the design.

Solution: Use centralized BOM management systems ensuring a single source of truth.

Pitfall 4: Lack of Alternatives

Problem: Critical components have only one option.

Consequence: When that component is unavailable, the entire project stalls.

Solution: Identify at least one alternative for each critical component.

Pitfall 5: Overlooking Manufacturing Feasibility

Problem: BOM includes miniature components extremely difficult to hand-solder.

Consequence: Poor sample production quality, unreliable test results.

Solution: Early manufacturing team involvement in BOM reviews.

Intelligent BOM Systems

Future BOM systems will integrate artificial intelligence and machine learning capabilities, able to:

Automatically identify component compatibility issues

Predict component supply risks based on historical data

Recommend alternative components based on design parameters

Update cost and lead time information in real-time

Sustainability Integration

2026 sample BOMs will pay more attention to environmental and social responsibility:

Marking components' environmental certification status

Identifying conflict mineral usage

Assessing carbon footprint and recyclability

Tracking supply chain transparency

Cloud Collaboration Platforms

Cloud-based BOM management systems will support real-time collaboration for global teams:

Multi-location simultaneous access and editing

Automatic change synchronization

Integrated chat and comment features

Direct connections to supplier systems

Digital Twin Integration

Sample BOMs will be tightly connected to products' digital twin models:

BOM changes automatically update virtual prototypes

Virtual testing validates BOM selections

Predicting product performance with different BOM scenarios

A sample BOM is much more than a shopping list—it's the first detailed map in the product development journey. It connects design concepts with physical reality, theoretical calculations with actual performance, team vision with market acceptance.

Creating a good sample BOM requires multidisciplinary collaboration: the technical vision of design teams, the supply chain wisdom of procurement teams, the practical knowledge of manufacturing teams, and the overall coordination of project management. When these perspectives merge into a clear, complete, and practical sample BOM, the chances of product success increase significantly.

Remember, in electronics product development, problems discovered and resolved during the sample phase are 10 to 100 times cheaper than those found during production. The sample BOM is one of your most important tools in this critical phase—worth investing time to get right.

Whether you're creating your first sample BOM or have managed dozens, continuously improving your BOM process can bring faster time-to-market, lower development costs, and higher final quality to your products. In this sense, a sample BOM is not just a list—it's the first cornerstone of product excellence.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..