Date: 2025-10-31

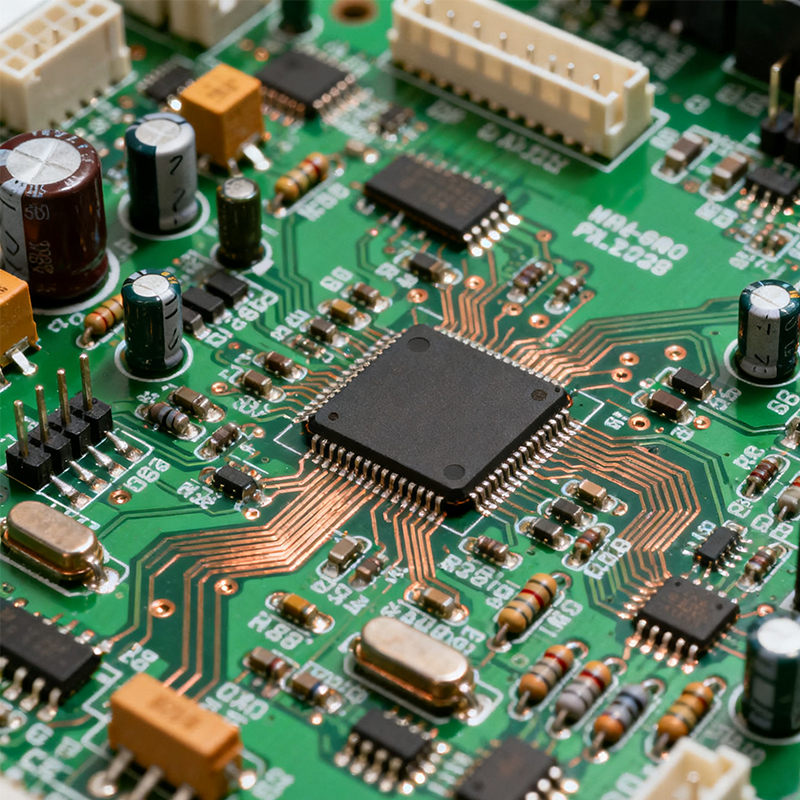

You know that frustrating moment when you spot those tiny solder balls scattered across your boards after reflow? They're not just cosmetic issues - these little troublemakers can actually cause short circuits and random failures in your products. We see this way too often in PCBA lines.

Here's how we're tackling this problem head-on:

We use a two-step approach that's both smart and effective. First, we prevent excess solder from being applied using precision stencil printing. Then, we zap away any remaining residue with targeted laser cleaning. It's like having a skilled surgeon for your PCBA boards.

When you work with us on this:

We'll walk you through our process in simple terms. "We're using laser settings that remove solder balls without damaging your components" - no confusing technical talk.

We customize the approach for your specific boards. High-density designs? Fine-pitch components? We've dealt with them all and know how to adjust our methods accordingly.

You'll see actual before-and-after photos of your boards, plus test data showing the improvement. We believe in showing you real results, not just making claims.

Why this solution actually works:

Your boards stop failing from random short circuits

You save money by reducing scrap and rework

Your customers get more reliable products

The numbers speak for themselves - we're seeing 90% fewer short circuit issues with this method. The precision printing prevents most problems upfront, while the laser cleaning catches anything that slips through.

We use this for everything from consumer electronics to medical devices where reliability is critical. The process works because it's both precise and thorough.

If you're tired of solder balls causing headaches in your production line, this two-step approach could be your answer. We're helping manufacturers create cleaner, more reliable boards by tackling solder residue at the source. Your yield improves, your costs go down, and you can finally stop worrying about those pesky solder balls ruining your boards.

We've helped companies just like yours solve this exact problem. The solution is here - you just need the right partner to make it work for you.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..