Date: 2025-11-03

Let's break down what makes single-sided circuit boards tick. These are your straightforward, no-nonsense boards where everything happens on one side - perfect for simpler electronics that don't need all the fancy stuff.

What Goes Into These Boards

First, you've got your base material - think of it as the foundation:

Paper-based boards (FR-1/XPC): Cheap and cheerful, good for basic household gadgets

Fiberglass boards (FR-4): The tough guys - handle heat better and last longer

Composite boards (CEM-1/CEM-3): Middle-of-the-road option

Aluminum boards: The cool customers - literally. They're built to handle heat in things like LED lights

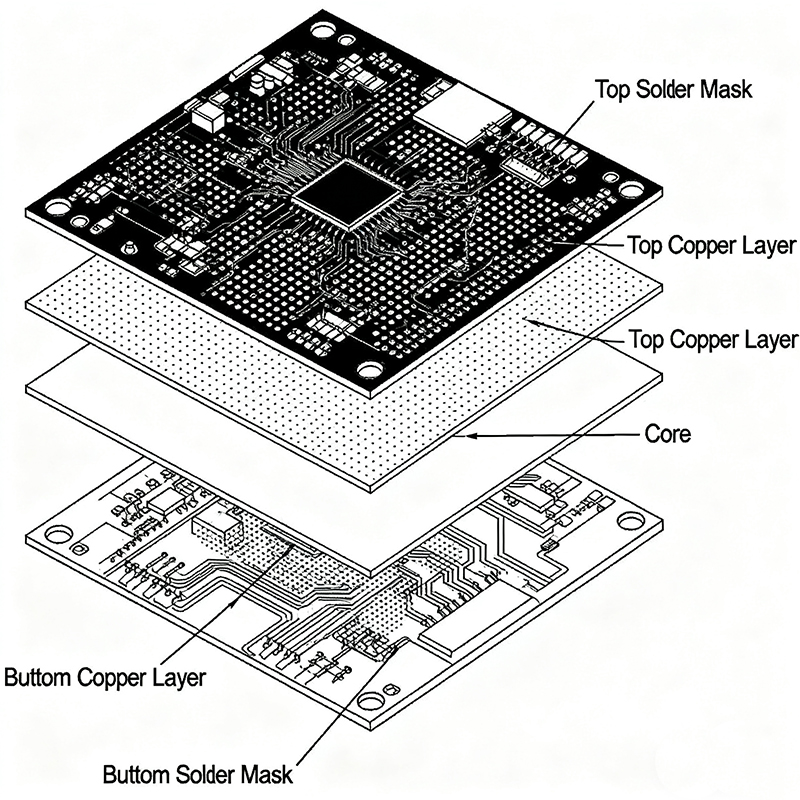

Then you've got the copper layer - that's your wiring. It's etched to create the actual circuit paths. For heavier electrical loads, we make the copper thicker so it can handle the current.

The solder mask is like a protective jacket over your copper wiring (usually green, but we can do other colors). It keeps things from shorting out and protects against damage.

Finally, the silkscreen is basically the labeling - it tells your assembly team where everything goes and helps with troubleshooting later.

Making It All Work Together

When we design these boards:

We think about heat management - putting hot components where they can breathe or using special boards that dissipate heat better.

We group similar functions together to avoid interference - keep the power stuff away from the sensitive signal areas.

We make sure there's enough room for assembly and repairs - nobody wants components crammed so tight you can't work on them.

The wiring follows some basic rules:

Ground lines need to be nice and wide

We avoid running sensitive signals parallel to each other for long distances

Sometimes we need to use jumper wires when circuits have to cross

How We Build These Things

The manufacturing process is pretty straightforward:

We start with a blank board and use a stencil to create the circuit pattern, then etch away the excess copper.

For putting components on:

Wave soldering works great for through-hole parts

Reflow soldering is better for surface-mount components

We finish the surface depending on what you need:

Tin coating: Good basic protection, budget-friendly

OSP: Thin protective layer, great for multiple heating cycles

Gold plating: Premium finish, super flat and durable

Making Sure It All Works Right

Before anything ships:

We test for shorts and opens

We check that components are working properly

We run stress tests to make sure the board can handle real-world use

We follow all the environmental regulations too - no lead, no halogens, all the good stuff.

The bottom line? Single-sided PCBA is your reliable workhorse - not overcomplicated, cost-effective, and perfect for applications where you don't need all the bells and whistles of more complex board designs.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..