Date: 2025-11-07

Forget the old-school way of poking parts through holes. That's for your grandpa's radio. Surface Mount Technology (SMT) is how everything modern gets made. It's faster, cheaper, and lets us build stuff that's tiny and powerful.

The Basic Idea: Just Stick 'Em On

Think of it like this: instead of components with long legs that need holes, we use flat little guys that sit right on the surface of the board. We put down some special sticky solder paste, a super-precise robot places the parts, and then the whole thing goes through an oven. The paste melts, cools down, and boom—everything's locked in place. Done.

The Line: How It Actually Goes Down

It's a four-step dance on a factory floor.

Paste Printing: This is like using a stencil. We take a thin metal sheet (a stencil) with laser-cut holes, lay it on the board, and spread a goop called solder paste over it. The paste squeezes through the holes onto all the spots where we need to make a connection later. It's gotta be just right—not too much, not too little.

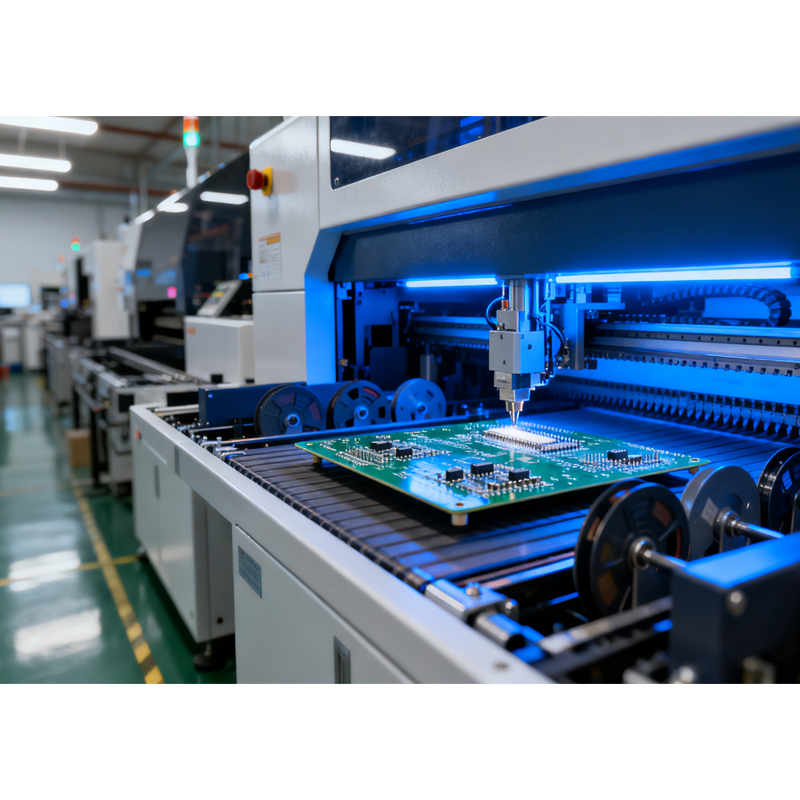

Placing the Parts: This is where it gets cool. A machine, called a pick-and-place, goes to work. It's got little vacuum nozzles that suck up parts from reels and trays. It has a super-powered camera that helps it see exactly where to put them. It slaps those tiny parts onto the paste with crazy accuracy. We're talking about precision within a hair's width. It's insane to watch.

The Magic Oven (Reflow): Now the board takes a ride through the oven. This isn't your average kitchen oven. It's a carefully controlled tunnel with different heat zones. It slowly heats the board up, hangs out at a specific temperature, then hits the peak heat where the solder paste melts and turns liquid, and finally cools it all down. This "temperature curve" is the secret sauce for making strong, reliable connections.

Checking for F*ck-ups (Inspection): Let's be real, sometimes things go wrong. A part might be missing, or there might be too much solder causing a short. So, we check. We use a camera system (Automated Optical Inspection or AOI) that scans every inch of the board to find these defects. For chips where you can't see the connections underneath (like BGAs), we use freaking X-ray machines to see inside. If a board fails, a tech pulls it aside and fixes it.

Why The Hell Is SMT Everywhere?

Simple. It's better than the old way in every way that counts.

It's Tiny: SMT parts have no legs. They sit flat, so we don't need to waste space drilling a million holes. This is the #1 reason your phone can do so much and still fit in your pocket.

It's Stupid Fast: A single machine can place tens of thousands of parts in an hour. Try doing that by hand. This speed is why electronics can be so cheap.

It's Tough: A good SMT solder joint is strong and can handle a lot of shaking and vibration better than an old wire stuck through a hole.

It Handles the Fancy Gear: Want a powerful brain for your gadget? Modern processors and chips only come in SMT packages (like BGAs). The old way simply can't handle them.

Where Is It? Look Around.

Seriously, just look.

In Your Pocket: Your smartphone, your wireless earbuds, your smartwatch.

In Your Car: Your screen, your backup camera, your radar sensors.

In Your House: Your TV, your game console, your router.

In Factories and Hospitals: Everywhere.

The Bottom Line

SMT isn't some fancy optional thing. It's the bedrock of modern electronics. It's the only way we can build the powerful, tiny, and affordable tech we use every day. Without it, we'd be stuck in the Stone Age.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..