Date: 2025-12-20

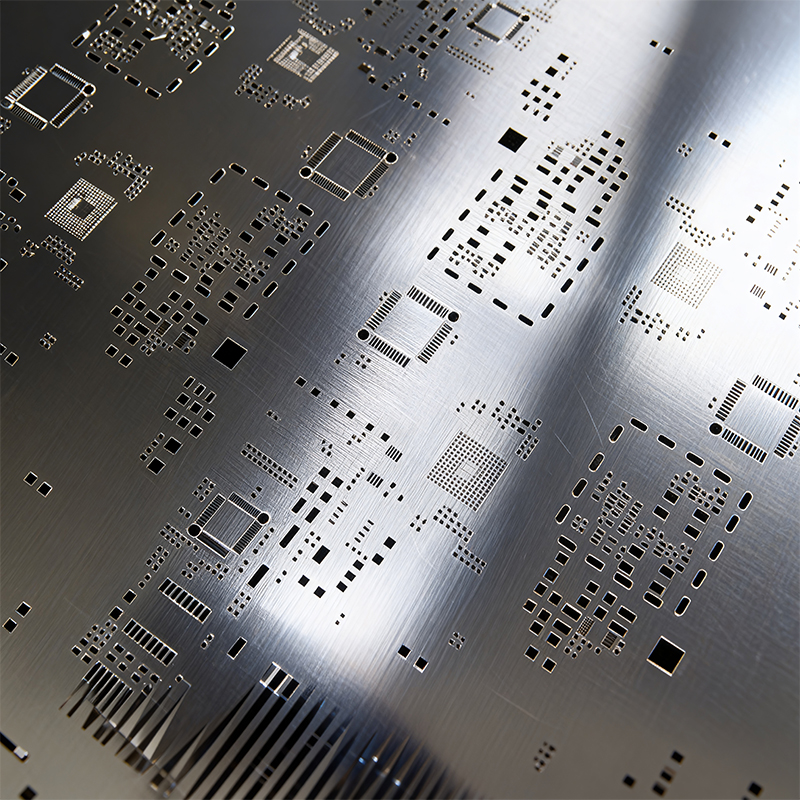

An SMT stencil is the precision tool at the heart of the modern electronics assembly line. It’s a thin sheet of metal—most often laser-cut stainless steel—that acts as a precise template for applying solder paste onto a printed circuit board (PCB). This critical step in Surface Mount Technology (SMT) manufacturing determines solder joint volume, placement accuracy, and ultimately, the functional reliability of the final electronic assembly.

Think of it this way: if the SMT assembly process is like building a micro-city of electronic components, the SMT stencil is the master blueprint that lays down the exact “cement” (solder paste) in the exact locations before the “buildings” (components) are placed. A flawless print is the non-negotiable foundation for a high-yield, reliable production run.

A stencil’s impact is felt at the very first step of SMT assembly and echoes throughout the entire process.

The Domino Effect of Stencil Quality:

Print Quality: Determines solder paste volume and alignment.

Placement Success: Components rely on precise, consistent paste deposits for proper self-alignment during reflow.

Reflow Outcome: Correct paste volume leads to reliable solder joints; incorrect volume causes defects.

Final Yield & Reliability: The cumulative result of steps 1-3 directly impacts functional yield and long-term product durability.

Common defects like solder bridging (shorts), insufficient solder (opens), and tombstoning (components standing up) can often be traced back to suboptimal stencil design or condition.

Not all SMT stencils are created equal. The choice depends on your board’s complexity, component mix, and volume requirements.

1. Laser-Cut Stainless Steel Stencils

Process: A CO2 or fiber laser vaporizes material to create apertures.

Best For: The majority of SMT applications; offers the best balance of precision, durability, and cost.

Kaboer’s Approach: We use high-end laser systems to ensure smooth aperture walls, minimizing paste drag and clogging for consistent prints.

2. Electroformed Nickel Stencils

Process: Created additively through nickel plating around a patterned mandrel.

Best For: Ultra-fine-pitch components (<0.4mm pitch, 01005/0201 sizes) where superior aperture wall smoothness is critical for paste release.

Key Advantage: Creates near-perfect trapezoidal apertures for excellent paste transfer efficiency.

3. Nano-Coated Stencils

Process: A laser-cut stencil treated with a ultra-smooth, non-stick coating (e.g., nickel-PTFE).

Best For: High-volume production where maximizing uptime is key; coating reduces paste adhesion, extending time between cleanings.

Our Use Case: We often recommend this for long production runs to reduce stoppages and maintain consistent paste volume.

4. Step Stencils (Hybrid Stencils)

Process: Features two or more foil thicknesses within one stencil, achieved via chemical etching or multi-layer lamination.

Best For: Mixed-technology boards requiring different solder volumes (e.g., fine-pitch ICs alongside large connectors or QFNs).

Design Insight: Our engineers can identify during DFM if a step stencil is needed to optimize paste volumes across varied components.

Understanding these specifications is crucial for specifying or evaluating an SMT stencil.

| Parameter | Typical Specification | Why It Matters |

|---|---|---|

| Foil Thickness | 100µm (4mil) - 150µm (6mil) | Directly controls solder paste volume deposited. Thinner for fine-pitch, thicker for high thermal mass components. |

| Aperture Design | Slightly modified from pad size | Apertures are often designed 1:1 with the pad or slightly undersized/oversized to optimize the solder joint shape and prevent defects. |

| Area Ratio (AR) | AR > 0.66 is target | AR = (Area of Aperture Opening) / (Area of Aperture Wall). This is the most critical rule. An AR below ~0.66 risks poor paste release, especially for small components. |

| Aspect Ratio | Aspect Ratio > 1.5 is target | Aspect Ratio = (Width of Aperture) / (Foil Thickness). Another key metric for paste release reliability. |

| Electropolishing | Standard or Enhanced | A post-laser electrochemical process that smooths aperture walls, improving paste release and reducing clogging. |

Pro Tip: A skilled PCBA partner will calculate the Area and Aspect Ratios for your smallest components during the DFM stage and suggest design adjustments (to pads or stencil specifications) if they fall into a risky zone.

Even with a good design, process issues can arise. Here’s a quick diagnostic guide:

| Problem | Potential Stencil-Related Cause | Corrective Action |

|---|---|---|

| Insufficient Solder Paste | Apertures clogged with dried paste; Stencil lifting too fast; Low Area Ratio design. | Increase stencil cleaning frequency; Adjust printer separation speed; Review aperture design for small components. |

| Solder Paste Smearing/Bridging | Worn or damaged stencil bottom; Poor gasketting (seal) between stencil and PCB; Squeegee pressure too high. | Inspect and replace damaged stencil; Ensure proper under-board support; Reduce squeegee pressure. |

| Uneven Paste Deposits | Warped stencil foil; Insufficient stencil tension; Worn squeegee blade. | Check stencil tension spec (should be 35-50 N/cm²); Replace stencil if warped; Implement regular squeegee blade replacement. |

| Poor Release for Fine-Pitch | Rough aperture walls; Inadequate Area Ratio. | Use electroformed or nano-coated stencils for fine-pitch; Revisit aperture design with your assembler. |

At Kaboer, based in Shenzhen, China, we view the SMT stencil not as a commodity, but as a critical process variable. Our integrated PCBA manufacturing approach ensures stencil performance is optimized from the very beginning.

Our Stencil-Centric Process Flow:

Proactive DFM & Stencil Strategy:

Before any tool is made, our engineers analyze your Gerber files. We automatically flag any pad geometries with challenging Area Ratios and provide actionable feedback. We’ll advise on the optimal stencil type (laser-cut, electroformed, nano-coated) and thickness based on your specific component mix.

Precision Stencil Fabrication & Qualification:

We partner with top-tier stencil vendors or manage in-house specifications to procure stencils built to exacting standards. Each new stencil undergoes a First Article Inspection and print trial, using Solder Paste Inspection (SPI) equipment to verify paste volume and alignment meet our stringent criteria.

Controlled Printing Process:

On our SMT lines, stencil printers are meticulously calibrated. Parameters like pressure, speed, and separation are documented for each product. We use SPI as a closed-loop feedback tool to make micro-adjustments, ensuring print consistency throughout the production run.

Lifecycle Management:

We track stencil usage and cleaning cycles. Our preventative maintenance schedule ensures stencils are re-coated or retired before print quality degrades, protecting your production yield.

For global electronics brands, this level of control is invaluable. It transforms the SMT stencil from a potential source of variation into a guaranteed foundation for manufacturing consistency. When you partner with Kaboer, you’re not just buying assembly capacity; you’re accessing a process engineering mindset that manages these critical details, allowing you to scale production with confidence.

To gauge a manufacturer’s expertise, consider asking:

“How do you determine the optimal stencil thickness and type for a new design?”

“Do you perform Area/Aspect Ratio analysis during DFM, and how do you resolve risky findings?”

“What is your process for validating and documenting a new stencil before production?”

“How do you monitor and maintain stencil performance during a long production run?”

The depth of their answers will reveal their commitment to process excellence.

In the pursuit of zero-defect manufacturing, mastery over the SMT stencil process is not an advanced topic—it’s a fundamental requirement. By investing in proper stencil design, specification, and process control, you build resilience into your supply chain from the very first step. Partnering with an assembler like Kaboer, who treats this tool with engineering rigor, ensures that this foundational element becomes a pillar of your product’s quality and reliability.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..