Date: 2026-02-03

When you look at a modern circuit board, the hundreds or thousands of tiny components aren’t held on with glue. They’re soldered using a special material called “Surface Mount Solder Paste.” Think of it as a temporarily sticky “metallic glue” that permanently solidifies when heated. It’s this paste that enables the precise, reliable electrical and mechanical connection between components and the board, making it an indispensable key material in modern electronics manufacturing.

Simply put, it’s a homogeneous paste mixture of microscopic solder alloy spheres suspended in chemical flux. At room temperature, it’s tacky like toothpaste, temporarily holding components in place. When heated in a reflow oven, it melts, flows, and then cools to solidify, forming strong solder joints.

To understand how it works, let’s break down its “recipe”:

Metal Alloy Powder: This forms the body of the solder joint, typically making up 85%-90% of the paste by weight. The most common is Tin-Silver-Copper alloy (e.g., SAC305: 96.5% Sn, 3% Ag, 0.5% Cu), prized for its good strength, reliability, and environmental compliance (lead-free).

Flux: This is the paste’s “chemical engine,” comprising about 10-15% by weight. Its role is critical:

Cleans: Removes oxides from component leads and PCB pads before soldering.

Protects: Prevents re-oxidation during the high soldering temperatures.

Reduces Surface Tension: Helps the molten solder alloy “wet” and spread effectively on the surfaces to form shiny, reliable joints.

Vehicle/Carrier System: This is the viscous medium that suspends the metal powder and carries the flux. It determines the paste’s rheological properties (like viscosity and thixotropy), allowing it to print smoothly through stencil apertures and hold its shape afterward without slumping.

The paste proves its value throughout the SMT assembly process:

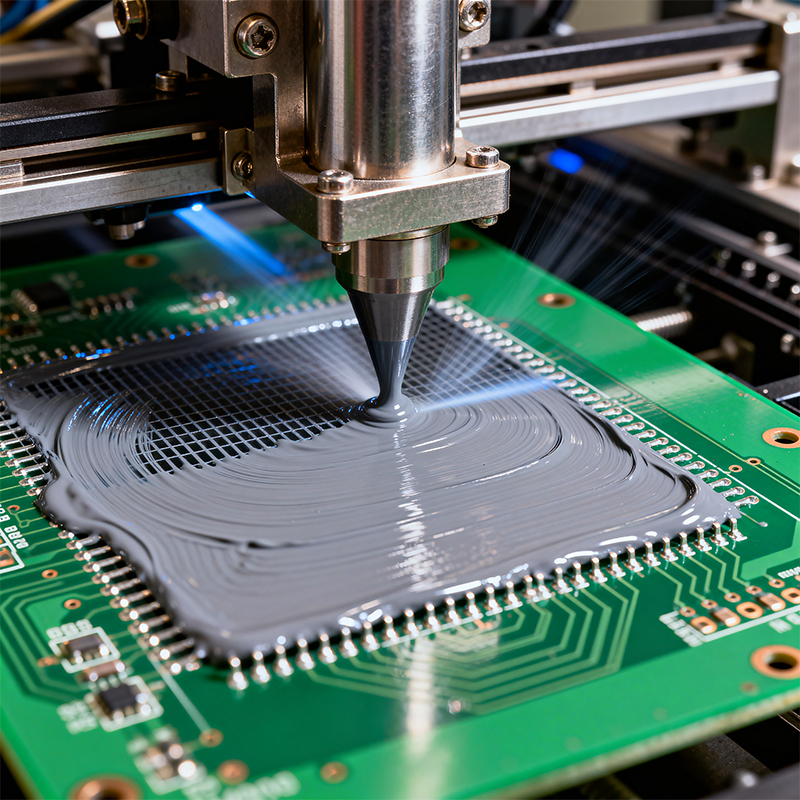

Printing: The paste is precisely deposited through a laser-cut stencil onto the PCB pads, forming little mounds or bricks.

Component Placement: The pick-and-place machine sets components onto these paste bricks. The paste’s tackiness holds them temporarily in place.

Reflow Soldering – The Critical Phase: As the board travels through the reflow oven, the paste undergoes four typical stages:

Preheat: Temperature ramps up slowly. The flux activates, and solvents begin to evaporate.

Soak/Activation: Temperature stabilizes. The flux works aggressively to clean the metal surfaces.

Reflow: Temperature peaks (typically 20-40°C above the alloy’s melting point). The metal powder melts completely into liquid solder spheres. Driven by flux and surface tension, it wets the component leads and board pads, forming a metallurgical bond.

Cooling: Temperature decreases. The liquid alloy solidifies, forming a solid, electrically conductive solder joint. The connection is made.

With many paste options from different suppliers, you can narrow choices based on:

Alloy Composition: Lead-free (SAC series) is the global mainstream for environmental compliance. For special thermal or strength needs, alloys with bismuth or higher silver might be used.

Powder Particle Size: Denoted by “Type” (e.g., Type 3, Type 4). A higher number means finer particles. Finer powder (like Type 4 for pitches below 0.4mm) is for ultra-fine-pitch components but may be more prone to oxidation.

Flux Activity: Typically categorized as ROL0 (low activity, high cleanliness), ROL1 (medium activity, most common), and ROL (high activity for difficult surfaces, residues may need cleaning). ROL0 or ROL1 are standard for electronics.

Viscosity: Like the difference between honey and ketchup. Choose based on print speed and stencil aperture size. High-speed printing or large apertures may require lower viscosity.

Storage & Handling: Paste must be refrigerated (typically 2-10°C), thawed before use, and handled on a “first-in, first-out” basis. Prolonged exposure to air degrades its performance.

Print Quality is Foundational: Printed paste should have well-defined, complete shapes with consistent height. A poor print is very difficult to fix later.

The Reflow Profile is Key: There’s no “universal” temperature profile. It must be set and optimized for the specific paste, board thickness, and components. This is central to achieving high yield.

Surface mount solder paste may seem humble, but it’s the cornerstone of the entire SMT process. It perfectly combines physical connection (metal powder) with chemical process (flux) in one material. Understanding its basic composition and function helps you communicate better with process engineers and choose the right “glue” for your product, ensuring robust and reliable soldering. After all, in electronics manufacturing, the quality of the solder joint directly determines the life of the product.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..