Date: 2026-02-03

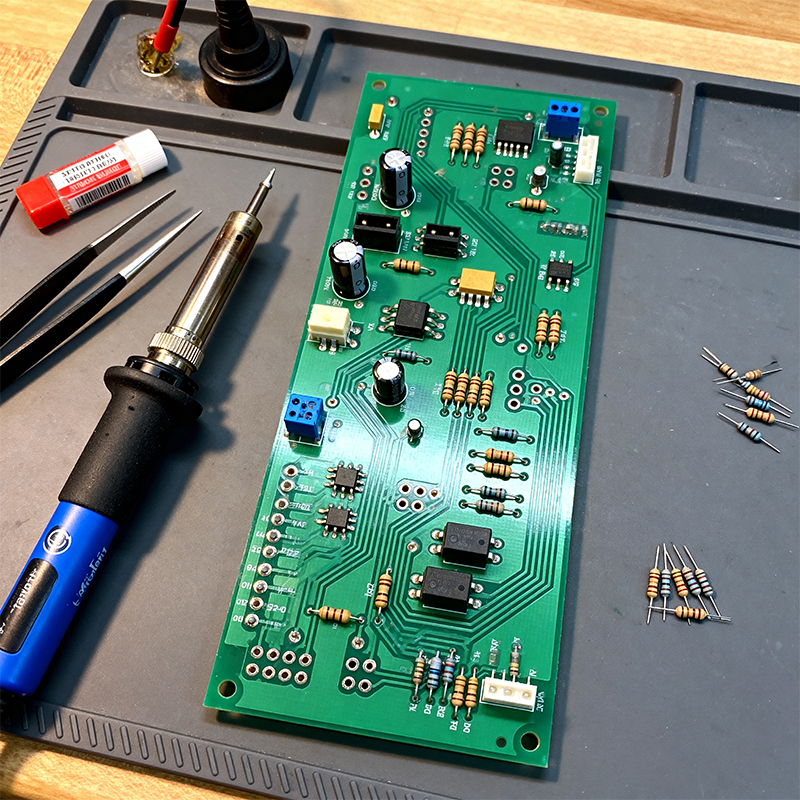

For many electronics hobbyists, students, and hardware startups, making a DIY PCB is a rewarding challenge. It allows you to quickly turn a schematic into a physical board, test ideas, and gain a fundamental understanding of electronics manufacturing. This guide walks you through popular DIY methods and explores the path to professional manufacturing when your project evolves from a "proof-of-concept" to a "reliable product."

Here are the most accessible ways to make PCBs at home or in a small workshop:

1. The Toner Transfer Method

This is the most popular and low-cost approach. First, print your PCB layout (mirrored) onto special glossy paper using a laser printer. Then, use a hot clothes iron or a dedicated transfer press to heat-press the toner onto a copper-clad board. Finally, immerse the board in an etching solution (like ferric chloride). The exposed copper is dissolved, leaving behind your circuit traces.

Pros: Low equipment cost (iron, printer), suitable for simple single-layer boards.

Cons: Success heavily depends on transfer quality; requires handling corrosive chemicals; limited to relatively wide traces.

2. The Photoetching Method

This method offers better precision. You start with a pre-sensitized copper board coated with a photoresist film. Place a transparent film with your printed circuit artwork on the board and expose it to UV light. The exposed photoresist hardens. Develop the board in a chemical solution to wash away the unexposed resist, revealing the copper to be etched.

Pros: Capable of finer traces and pads.

Cons: More process steps, requires a dim environment, and pre-sensitized boards are more expensive.

3. CNC Milling / Engraving

Using a small desktop CNC machine, a milling bit physically removes unwanted copper from the board based on your design file, carving out the traces.

Pros: No chemicals needed; clean process; allows instant modifications and can also cut the board outline.

Cons: Higher initial machine cost; slow milling speed; generates noise and dust; challenging for very fine traces.

The core value of DIY PCB fabrication lies in rapid prototyping and the joy of learning. It can yield results within hours and is perfect for education, art projects, or very early-stage functional verification.

However, as your project goals shift from "making it work" to "making it reliable and marketable," the limitations of DIY become apparent:

| Consideration | DIY PCB Fabrication | Professional PCB Manufacturing (e.g., Kaboer) |

|---|---|---|

| Capability & Precision | Typically limited to 1 or 2 layers with trace/space >0.3mm. Vias, solder mask, and silkscreen are difficult. | Easy production of multilayer boards, blind/buried vias, supports <0.1mm traces, automatic solder mask & silkscreen. |

| Materials & Reliability | Basic FR4 material, no testing. Long-term reliability, insulation, and thermal performance are uncertain. | Certified materials, electrical testing, impedance control, ensuring performance and long-term stability. |

| Surface Finish | Usually bare copper, prone to oxidation, poor solderability, not suitable for storage. | Multiple finishes (ENIG, HASL, OSP) for excellent solderability and oxidation resistance. |

| Efficiency & Scale | Manual process. One board can take half a day. Cannot produce perfectly identical copies. | Fully automated. Standard prototypes in 24-48 hours. Seamlessly scales from small to large batches. |

| True Cost | Low material cost per experiment, but high time cost and failure rate. Includes hidden equipment/chemical management costs. | Low per-unit cost at scale. Frees your time from manual labor for higher-value design and development work. |

If your circuit involves microcontrollers, dense components, or high-speed signals, or if you plan to build even a few dozen units for testing, moving to a professional service becomes essential.

It's not just about quality, but efficiency and scalability. A professional manufacturer provides:

Design for Manufacturing (DFM) Checks: Identifies potential issues before production.

A Reliable Supply Chain: Ensures consistent materials and processes for every order.

Repeatable Quality: Guarantees your 1st prototype and your 1000th unit perform identically.

Understanding the joys and limits of DIY highlights the value of professional manufacturing. This is the core support Shenzhen Kaboer Technology offers to makers, hardware startups, and electronics manufacturers worldwide.

Based in Shenzhen, the heart of global electronics manufacturing, we operate our own advanced PCBA factory. We deeply understand the pains of transitioning from a "desktop prototype" to a "market-ready product."

Choosing Kaboer means you can:

Seamlessly Transition Your Design: Whether you started with a DIY proof-of-concept or designed directly in an EDA tool, simply send us your Gerber and BOM files. We'll transform them into industrial-quality boards.

Get "Prototype Speed" with "Production Quality": Our processes are optimized for small-batch and prototype orders, offering competitive pricing and fast turnaround for high-quality boards suitable for rigorous testing and early sales.

Focus on Core Innovation: Leave the complexities of fabrication, component sourcing, and quality control to us. Free your team to focus on product design, software, and market strategy.

DIY PCB fabrication is a wonderful start to the electronics journey—it ignites ideas and teaches fundamentals. And when your idea is ready for the world, you need a reliable professional partner to make it a robust, scalable reality.

Ready to turn your great design into a manufacturable product? Contact Kaboer today, and let's start with a professional prototype.

Kaboer manufacturing PCBs since 2009. Professional technology and high-precision Printed Circuit Boards involved in Medical, IOT, UAV, Aviation, Automotive, Aerospace, Industrial Control, Artificial Intelligence, Consumer Electronics etc..